Navico INC Belcher Rd, Suite 128, Largo, Florida 33773, USA Telephone Facsimile

|

|

|

- Florence Flowers

- 6 years ago

- Views:

Transcription

1 YP500

2 E03270 Issue 1.0 Navico Ltd Star Lane, Margate, Kent CT9 4NP, UK Telephone +44 (0) Facsimile +44 (0) sales@navico.co.uk 51º21.87N 001º23.43E Navico INC Belcher Rd, Suite 128, Largo, Florida 33773, USA Telephone Facsimile navico@aol.com Navico France SARL Urba Parc 3, 75 Rue Rateau 93120, La Courneuve, Paris, France Telephone +33 (0) Facsimile +33 (0) navicofrance@compuserve.com Navico Deutschland GmbH Lollfuß 43-45, D Schleswig, Germany Telephone Facsimile navicod@aol.com Navico Ltd The technical data, information and illustrations contained in this publication were to the best of our knowledge correct at the time of going to print. We reserve the right to change specifications, equipment, installation and maintenance instructions without notice as part of our policy of continuous development and improvement. No part of this publication may be reproduced, stored in a retrieval system or transmitted in any form, electronic or otherwise without prior permission from Navico Ltd. No liability can be accepted for any inaccuracies or omissions in the publication, although every care has been taken to make it as complete and accurate as possible. MDL 27/2/1998 apple

3 6.6 Service & Warranty This unit is guaranteed for 12 months from date of retail sale. If it is necessary to have the unit repaired, return it carriage prepaid to the agent in the country of purchase with a copy of the receipted invoice showing the date of purchase. Where possible, return all the components unless you are certain that you have located the source of the fault. If the original packing is not available, ensure that it is well cushioned in packing; the rigours of freight handling can be very different from the loads encountered in the marine environment for which the unit is designed. If returning the YLA500 drive for service, ensure that the reservoir breather cap is removed and replaced with the transit cap fitted when the unit was first supplied For Worldwide Warranty details, please refer to the Warranty Card supplied with this unit. A list of official worldwide Navico dealers is included in the Warranty Card. 1. General 2. Operation CONTENTS 1.1 Introduction 1.2 Technical Summary 2.1 General 2.2 Autopilot Mode (Compass) 2.3 Adjusting Course 2.4 Steer To Wind 2.5 Navlock 2.6 Autotack Autotacking in Compass Mode Autotacking in Wind Mode Autotacking in NavLock Mode 3. Performance Optimisation 4. Installation 5. Commissioning 6. Appendix 3.1 Rudder Movement (Gain) Adjusting Gain 3.2 Seastate 3.3 Autotrim 4.1 Drive Installation 4.2 Installation Checklist - YLA Linear Feedback Unit YLF Fitting Control Unit YC Fitting Compass Unit PHS Fitting Course Computer YCP Electrical Installation 4.8 Interfacing via NMEA 5.1 Commissioning Checks 5.2 Compass Orientation 5.3 Setting Rudder Limits 5.4 Seatrial / Compass Calibration 6.1 Advice On Operation 6.2 Warning 6.3 NMEA Sentences Received 6.4 Fault Finding 6.5 Optional Accessories 6.6 Service & Warranty

4 1 General 1.1 Introduction The Navico Yachtpilot is a powerful and compact below deck autopilot suitable for mechanically steered sailboats up to 14m (45 Ft) in length. Combining highly sophisticated electronics with advanced software and powerful drives, it is capable of providing reliable and accurate steering performance under a variety of different conditions with minimal current consumption. The Yachtpilot has been designed so that while it represents the state of the art in marine autopilots with many advanced features, it remains very simple to operate, using only five keys to access all functions. The status of the unit is indicated clearly by five LEDs. To ensure the best results from your Yachtpilot it is essential that the unit is installed correctly - please read this manual thoroughly before attempting installation and use. Thank you for choosing Navico We hope you will also be interested in our full range of marine electronic equipment, which are all manufactured to the same high standards as the Yachtpilot. Please contact your nearest Navico dealer for a catalogue showing our increasing range of high tech navigational instruments, GPS, autopilots, radar and VHF radio sets. Navico operate a policy of continual development and reserve the right to alter and improve the specification of their products without notice. In the event of the Yachtpilot YP500 failing, the LED located under the terminal bay cover can be used to identify the potential source of the problem - Flashes Diagnosis Fault Location 1 Pump activated, but no rudder movement detected YLA500, YLF500 2 Invalid rudder feedback reading from YLF500 YLF500 4 Current limit exceeded YLA500, YCP500 5 Control unit not connected YC500 6 No compass data received PHS500 7 No compass/controls detected YC500, PHS500, YCP500 8 Rudder limits not set / calibration failed YLF500, YCP Optional Accessories The following optional accessories for the Yachtpilot YP500 are available from your Navico dealer. Please quote the correct part number when ordering. A U T O Yachtpilot is a Registered Trade Mark of Navico Ltd LIGHT SET ALARM DODGE / 38 mm (1.5 in) 150 mm (5.9 in) 19 mm (0.75 in) 69 mm (2.7 in) 68 mm (2.67 in) GAIN 40 mm (1.6 in) PJB500 PJB mm (6.52 in) GAIN POWERPILOT 110 mm (4.33 in) 94 mm (3.7 in) YCJ500 Additional Control Station + Junction Box PYR500 Hand Remote + Junction Box YCP mm (2.0 in) 188 mm (7.4 in) mm (25.64 in) midstroke 219 mm (8.76 in) max

5 6.4 Fault Finding Symptom Pilot will not enter mode. Yachtpilot drops back into Standby Mode. Helm is hard over and alarm is continuously on. Loss of course in Steer To Wind Mode Cannot select NavLock Mode Cannot select Steer To Wind Mode Autotack function not working Pilot will not allow rudder travel limits to be set Pilot does not maintain an accurate course in Compass Mode. Compass will not auto calibrate Pilot consistently over or under compensates when a course error is detected. Probable Cause Rudder limits not entered. Rudder limits configuration failed. Faulty connection to PLF500 Faulty connection to PHS500. Fault with course computer. Low supply voltage to Drive Unit or Course Computer. Steerage way insufficient to control course. Sails are backed. Apparent wind has become too light to give a consistent direction. Navigational data not available. Incorrect NMEA format or sentences are being transmitted. Destination not programmed in navigator. Windvane is not connected. Incorrect NMEA format or sentences are being transmitted. Pilot is in NavLock Mode. Pilot is in Steer To Wind Mode and a) apparent wind is >90º b) autotack being attempted is in the wrong direction. Insufficient boatspeed to complete tack. Power cable gauge too small. YLF500 incorrectly wired or installed. PHS500 compass has not been calibrated. PHS500 compass is encountering magnetic interference. Turn rate too fast/slow Conditions too rough Deviation detected is too large Gain setting is respectively too high or too low. Maximum limits of YLF500 have not been set. Remedy Enter rudder limits (see 5.3) Check all connections. Replace fuse. Check battery charge. Check all electrical connections and supply cables. Reset the vessel on course and reengage pilot. Change to Compass Mode Check NMEA connections. Refer to section 6.3 for correct NMEA0183 sentence formats. Activate Route/Waypoint from receiver. Check NMEA connections. Refer to section 6.3 for correct NMEA0183 sentence formats. Exit NavLock Luff up until apparent wind is less than 90º Check recommended cable sizes (Fig 4.13) Check drive wiring. Check YLF500 wiring & installation. Refer to section 5.4 to calibrate the compass to compensate for magnetic deviation. Check area around PHS500 for magnetic objects (loudspeakers, heavy current carrying cables etc). Min compass safe distance is 1m. Flashing LEDs above Port/Starboard keys indicate if turn rate is too fast or slow. Calibration should be attempted in calm conditions Check area around compass for metallic objects/speakers etc (min safe distance - 1m/3ft) Adjust gain to suit boat s speed (Low Speed - High Gain; HIgh Speed - Low Gain). Set YLF500 limits (section procedure 1). 1.2 Technical Summary Course Computer YCP500 Supply Voltage Feedback Drive Output - NMEA Format Hydraulic Linear Drive Peak Thrust Operating Stroke Yachtpilot Compass GPS / WIND (NMEA) Yachtpilot Drive SPECIFICATIONS 12v DC (10v-16v) Linear Feedback Unit 15 Amps Max NMEA kgs 200mm (8.0 in) Yachtpilot Course CC100 Computer YCP500 Yachtpilot Control Unit GAIN Optional Second Control Fig Yachtpilot Installation GAIN Yachtpilot Linear Feedback PJB500

6 2 Operation 2.1 General The keypad of the Yachtpilot has been designed to be very simple to operate. Using only five keys (Fig 2.1) it is possible to perform precise course adjustments and navigational functions. The unit powers up in Standby Mode, indicated by a flashing LED next to the key (Fig 2.2). The control unit s LEDs are always dimly lit, which provides night illumination for the keypad. All functions are confirmed audibly by a beep and visually by the LEDs, so the status of the pilot can always be confirmed at a glance. 2.2 Autopilot Mode While in Standby Mode, the rudder can be manually driven in and out by pressing the arrowed Port and Starboard keys, which allows power steering of the boat. To engage Autopilot Mode, simply press the key, and the Yachtpilot will lock onto the current course. The LED next to this key will stop flashing and remain permanently lit as long as the pilot is in Autopilot Mode (Fig 2.3). To lock the pilot onto the desired course, either steer the correct course and then engage the autopilot, or engage the autopilot and then adjust the heading until the correct course is being steered (see section 2.3). If the key is pressed and held, the pilot will beep a second time and lock onto the previously used heading (no previous heading will be recalled if the unit has just been switched on). Fig Yachtpilot keypad Fig Standby - pilot disengaged Fig Engaging Autopilot Mode 6.3 NMEA Sentences Received The NMEA0183 information required for full functionality while in NavLock is as follows - Cross track error Bearing to destination waypoint Arrival at waypoint indication This information is extracted from the following NMEA0183 sentences - XTE BWC BWR APA APB RMA RMB RMC Cross Track Error Bearing & Distance To Destination Waypoint (Great Circle) Bearing & Distance To Destination Waypoint (Rhumb Line) Cross Track Error, Bearing To Destination Waypoint and Arrival At Waypoint Cross Track Error, Bearing To Destination Waypoint and Arrival At Waypoint Boat Speed Cross Track Error, Bearing, Distance and Arrival At Arrival Waypoint Boat Speed NOTE - The Cross Track Error (XTE) information has a maximum value of 1.27 Nautical Miles. If the XTE exceeds this while using NavLock, the Yachtpilot will sound an alarm, exit NavLock Mode and return to Compass Auto Mode. For Steer To Wind Mode, the Yachtpilot extracts the apparent wind angle from the following NMEA0183 sentences - VWR MWV Apparent Wind Speed & Angle Wind Speed & Angle 2.3 Adjusting Course While in Autopilot Mode, precise course adjustments can be easily made. By pressing either the Port or Starboard key once, a 1º course adjustment will be made in the specified direction (Fig 2.4). This is confirmed by a single beep, and the relevant Port or Starboard LED will flash once. By pressing and holding Fig Course adjustment to Port

7 6 Appendix 6.1 Advice On Operation The Navico Yachtpilot when used correctly can maintain as good a course, on most points of sail as a skilled helmsman, with the advantage that it never loses concentration where a human may begin to show lapses of concentration after as little as ten minutes. There are certain circumstances however, where a human pilot has the advantage in being able to anticipate events which no autopilot can sense, typically in a heavy following sea. The following advice should improve the efficiency of the Yachtpilot - 1. When sailing close to the wind it is easy to forget to trim the mainsail, allowing excessive weather helm to build up. Where a human helmsman would complain, the Yachtpilot will struggle on and the boat will be sailed less efficiently. While a human normally likes to feel some weather helm, this is not necessary for the Yachtpilot. Power consumption, wear and drag will be greatly reduced if the mainsail is freed or reefed a little sooner than normal when sailing manually. 2. It is also advisable when sailing close hauled to set a course a few degrees free of that normally sailed under manual control, to avoid luffing into the wind. 3. When running dead downwind, a human pilot can see visual signs warning him if the boat is about to gybe, which the Oceanpilot cannot sense. Therefore, when under autopilot it is advisable not to sail as close to the gybe as you may do when sailing manually. 4. When broad reaching or running fast, particularly with quartering waves, a helmsman will naturally apply periodic larger angles of helm than when beating or sailing slowly. This is the equivalent of increasing rudder Gain, and it may be a good idea to adjust the Gain setting. Many people prefer to find a compromise setting which is used for all sailing, but with practice it can be optimised for different conditions e.g. low for motoring in a calm sea or high for running fast. If the Gain is set too low, the boat will yaw because insufficient rudder is applied in time; if the gain is too high, the boat will continually overcorrect on each deviation, increasing power consumption. 6.2 Warning The Yachtpilot is a highly advanced autopilot, and a valuable aid to enjoyable sailing. However, it would be a mistake to become complacent. Like all electronic navigational equipment, it is an aid to navigation and should not be used as a substitute for conventional navigational practice. Remember - Maritime Law* requires that you keep a good look out at all times. the key, 10º course adjustments will be made, confirmed by a double beep and a double flash of the Port or Starboard LED. 2.4 Steer To Wind As the Yachtpilot is fully NMEA0183 compatible, it is able to make use of wind data from an NMEA source and sail to the apparent wind angle rather than a compass course. Please refer to section 4.8 for more details on interfacing the Yachtpilot to an NMEA source. If no wind information is present, the Yachtpilot will not enter Steer To Wind Mode. To select Steer To Wind Mode, the unit must be in Autopilot Mode. Press and hold both the Port and Starboard keys together until a double beep is heard (Fig 2.5). Both the Port and Starboard LEDs will flash simultaneously while the pilot is in Steer To Wind Mode. To switch back to Compass Mode, simply press and hold the Port and Starboard key together again until a double beep is heard. While in Steer To Wind Mode, engaging the autopilot will lock the Yachtpilot onto the current apparent wind angle being sailed. Any course adjustments made will be relative to the apparent wind angle, rather than the compass heading as when in Compass Mode. Please note that some of the standard key stroke functions may have a different effect in Steer To Wind Mode than when in Compass or NavLock Mode. Refer to sections & for more details. Note that NavLock cannot be selected while in Steer To Wind Mode - to initiate, first return to Compass Mode. Fig 2.5- Selecting Steer To Wind Mode *IMO International Regulations for Preventing Collisions at Sea, Part B Rule 5 (1972)

8 2.5 NavLock The Yachtpilot s inbuilt NMEA interface allows it to be connected to NMEA0183 compatible equipment such as GPS, Decca, LORAN, Plotters and other navigational receivers. Once interfaced with navigation equipment via NMEA, the Yachtpilot can steer using data from this source in addition to the internal compass, allowing a highly accurate course to waypoint (Fig 2.6). To access NavLock the pilot must be in Auto mode and receiving waypoint or route data from the navigational receiver. Press the key to activate Navlock (Fig 2.7). The LED next to the key will light and the Yachtpilot will steer to the first waypoint, using Cross Track Error and Bearing To Waypoint information from the navigational receiver to maintain an accurate course. If no NMEA information is being received, the pilot will beep twice and will not enter Navlock mode. If the key is pressed while in Standby mode, the pilot will beep once to indicate that Navlock mode is available when in Auto Mode, or twice to indicate that Navlock mode will not be available in Auto Mode. On arrival at the target waypoint an intermittent alarm will sound. As a safety feature to avoid an unexpected course change, the next waypoint will not be automatically loaded until the key is pressed. When the boat reaches the final waypoint, the Yachtpilot will continue its current course under Compass Mode. Note - If any course correction is made while in Navlock Mode using the Port and Starboard keys, the boat will gradually return to the original track (Fig 2.8). This allows the boat to dodge an obstacle without exiting Navlock or having to reset the boat on the correct course. Fig Navlock - Steering by satellite Fig Initiating NavLock Original Track Course change to avoid obstacle Fig Course Adjustment in Navlock Mode 5.4 Seatrial / Compass Calibration Before proceeding any further, it is recommended that the compass is calibrated to compensate for any magnetic deviation caused by ferrous objects surrounding it on the boat (speakers, superstructure etc). With the boat motoring along slowly (2-3 knots) in calm conditions press the STBD key a number of times to induce a slow clockwise rotation of the boat (approx 3º/sec). Press and hold the, followed by the Port and Starboard keys simultaneously to enter Auto Compass Calibration Mode (Fig 5.4). Allow the boat to turn through a minimum of 1 1 / 4 turns (450º) in approximately two minutes, during which time the fluxgate compass will automatically calibrate itself. If the rate of turn is too high, the Port LED will flash (Fig 5.3) indicating that it is necessary Fig Auto Compass Calibration to decrease the rate of turn -press Port. If the rate of turn is too slow the Starboard LED will flash, indicating that it is necessary to increase the angle of turn - press Starboard. It is recommended that the calibration is restarted if the Port LED flashes more than twice. A double beep will indicate that the calibration has been successful, and the Yachtpilot will return to Standby Mode, indicated by the / LED flashing. If the calibration has been unsuccessful after a period of four minutes, an alarm will sound. Power down the Yachtpilot and repeat, following the above directions carefully. If the compass will still not calibrate then it is likely that the deviation being detected is too great, which may be due to the compass being too close to a metallic or magnetic object (minimum safe distance - 1m (3 Ft). Move the compass to a position as close to the ideal location as possible (see section 4.4), but away from speakers, metallic superstructure etc. This procedure should only need to be performed once, unless the compass unit is changed, repaired, relocated or if any metallic objects have been installed or removed in the vicinity of the compass since it was calibrated. In the interests of accurate performance, always bear in mind the location of the compass when installing any metallic objects on the boat. After calibrating the compass, perform the following procedure - 1. Hold the course steady for 5-10 seconds. 2. Press to engage the Yachtpilot and lock onto the displayed heading - in calm conditions a constant heading should be held. 3. Alter course to Port and Starboard - the course change should be smooth without any sign of overshooting. 4. Look back at the wake of the boat to get an indication of the steering performance. If there is any evidence of snaking or S-ing, try decreasing the Gain setting (see section 3.1). 5. If a navigational receiver or windvane is connected to the Yachtpilot, the NavLock and Steer To Wind functions should be tested over a longer distance.

9 5.3 Setting Rudder Limits This two-stage procedure is used to - a) define the maximum limits of the YLF500 pushrod stroke. b) to define the rudder stop and centreline position of the rudder. This information will be permanently stored in the course computer memory. Therefore, it will not be necessary to repeat this procedure unless the course computer is replaced, or the YLF500 is replaced or repositioned. With the power off, press the, and keys. Holding these keys down, switch the Yachtpilot on (Fig 5.3). The Port LED will flash and the Starboard LED will light. Disconnect the feedback unit pushrod from the ram and remove it fully from the feedback unit (the rod is not physically attached to the feedback body and can be removed easily). Then fully insert the pushrod into the feedback unit body as far as it will go. This will define the maximum limits of the YLF500 in the course computer s memory. Reconnect the pushrod to the ram, and set the rudder limits as follows - Turn the wheel hard over to port, and press Port. If the Port setting is accepted, the LED above the Starboard key will then flash. Turn the wheel hard over to starboard and press Starboard. If the individual rudder setting is not accepted, the control unit will beep and the appropriate LED will continue to flash.. If the Starboard setting is accepted, the LED over the key will start flashing. Turn the wheel to the centre position, and press. The Yachtpilot will then store these rudder settings. If the configuration is successful, the control unit will beep for 2 seconds and enter Standby mode. If it is not successful, all the LEDs will flash and the alarm will sound. Follow the above procedure again carefully. Note that the pilot will not enter Auto mode until the rudder limits have been set. 2.6 Autotack The Yachtpilot has a built-in autotack facility, allowing easy tacking of the vessel when single or short handed. An autotack is only possible when in Auto Mode. To initiate autotack, press and hold the Tack key, followed by either the Port or Starboard key, depending on which direction you wish to tack (Fig 2.9). The operation of the Yachtpilot will differ during an autotack depending on whether the pilot is in Compass or Wind Mode: POWER ON Fig Setting rudder limits Autotacking In Compass Mode If in Sail To Compass Mode (default), the Yachtpilot will then tack the vessel in the selected direction. The Yachtpilot has a factory preset autotack angle of 100º, however this can be adjusted to any value between 40 and 140º using the optional PYR500 hand remote Autotacking In Wind Mode (Section 2.4) When in Steer To Wind Mode, the Yachtpilot will only allow an autotack if the apparent wind angle is less than 90º (i.e autotack is disabled if sailing downwind). The pilot will tack the vessel through to the same apparent wind angle, but on the opposite tack. NB - In this mode, the Yachtpilot automatically prevents tacking in the wrong direction eg, If on Port tack, only an autotack onto Starboard tack will be possible. In all cases, the autotack is confirmed by a long beep, with the relevant Port or Starboard LED flashing during the course change NavLock (Section 2.5) The autotack facility is disabled while in NavLock mode. Fig Initiating Starboard autotack

10 3 Performance Optimisation The Yachtpilot uses highly advanced steering software, which constantly assesses how the boat is being affected by the prevailing conditions. By adjusting its own performance, the pilot is able to maintain the most accurate course for these conditions, just as a human pilot would. Thus, in a rough sea the pilot is not overworked and battery drain is kept to a minimum. While the gain is adjusted manually to suit the boat, all other performance functions are totally automatic. 3.1 Rudder Movement (Gain) The Yachtpilot will make corrections to compensate for heading errors, in order to keep the boat on course. The amount of rudder correction made is set by the Gain (sometimes referred to as the rudder ratio). The Gain setting can be compared to driving a motor vehicle - at high speeds, very little wheel movement is necessary to steer the vehicle (LOW gain). When driving at slow speeds, more wheel movement is necessary (HIGH gain). Fig 3.1A shows the effect of setting the Gain too low: the boat takes a long time to return to the correct heading. Fig 3.1B is ideal, where errors are quickly corrected. Fig 3.1C occurs when the Gain too high, causing the boat to S, or oscillate around the correct heading. Excessive Gain (Fig 3.1D) causes instability of course, leading to increasing error. A B C D Fig Effects of Gain setting 5.2 Compass Orientation The PHS500 compass can be mounted in one of four orientations - 0º, 90º, 180º or 270º to the bow (Fig 5.1). The factory preset is 0º (pointing forward). If the compass is mounted in any other orientation, this must be programmed in before using the pilot. With the power switched off, press and hold while turning the power on. The Port, Starboard, / and LEDs will light continuously, and the LED will flash and beep, indicating the current compass orientation setting - Beeps/Flashes Compass Pointing 0 0º (To Bow) 1 270º (To Port) 2 180º (To Stern) 3 90º (To Starboard) Use the Port and Starboard keys to set the correct compass orientation (Starboard to rotate setting clockwise, Port anticlockwise - Fig 5.2). Press / to accept the entered setting and return to Standby mode. BOW 0º (No flashes) 270º (1 flash) 90º (3 flashes) 180º (2 flashes) Fig Compass orientation POWER ON Adjusting Gain The Gain setting can be adjusted in either Standby or Auto mode, allowing the performance of the pilot to be optimised underway. Press and hold the key, followed by the key (Fig 3.2). The LED above the key will flash and a repeated sequence of beeps will be heard. The number of flashes and beeps in the sequence indicates the level of the Gain setting. To increase the Gain press the Starboard key the required number of times, to a maxi- Fig Accessing Gain setting Fig Setting compass orientation

11 5 Commissioning 5.1 Commissioning Checks After installation has been completed, the following checks should be made before use - 1. Installation check - ensuring that the installation of all the components in the system is mechanically and electrically correct. 2. Seatrial - Auto compass calibration. The pilot should be set up for optimum course keeping ability. If external NMEA equipment is interfaced with the pilot, NavLock / Steer To Wind should also be tested. CABLING 1. Are all the connections secure and all wire ends tinned?? 2. Does all wiring meet recommended lengths and sizes for the current/voltage? 3. Does the input power line have the correctly rated fuse or circuit breaker? 4. Where possible, are the cables run away from existing cables which carry radio frequency or pulsed signals? (1m / 3 Ft distance is recommended). 5. Are cables neatly tied or clamped to prevent friction damage? (Ties every 0.5m / 1.5 Ft intervals recommended minimum). COURSE COMPUTER YCP Is the Course Computer in a dry location away from excessive heat and vibration? 2. Is the Course Computer mounted on a vertical surface, with the cooling fin uppermost? 3. Is the Course Computer securely attached to a permanent structure? 4. Are all the cables properly fed through the cable clamp channels? LINEAR DRIVE YLA Is the drive unit installed in a dry area? 2. Is the drive secured to a substantial structure on the vessel? 3. Has the drive been mounted in the midstroke position when rudder is amidships? 4. Is the correct tiller arm length (T) and offset length (O) correct for the vessel s rudder angle? 5. Is the tiller/quadrant of the vessel reinforced if necessary? 6. Are the end stops limiting the rudder movement rather than the drive unit? 7. When the actuator is driven hard over from lock to lock, does it encounter any obstructions? 8. Has the reservoir cap fitted for transit been replaced by the breather cap supplied? LINEAR FEEDBACK UNIT YLF Has the unit been securely attached to the YLA500 using the supplied mounting saddles? 2. Is the full stroke of the YLF500 between 150mm and 190mm (6.0in to 7.5in)? 3. Is the YLF500 correctly aligned with the YLA500? 4. Has it been fitted so that the rod does not bend or distort at any point of steering? 5. When driven hard over from lock to lock, is the YLF500 free from any obstructions? COMPASS PHS Has the compass been mounted in a vertical position? 2. Has the compass been mounted in a position away from ferrous materials, loudspeakers, heavy current carrying cables or other magnetic/electronic equipment to avoid deviation? 3. Has the compass been mounted as near as possible to the centrepoint of the boat to minimise gimbal disturbance? mum level of 9. To decrease the Gain press the Port key the required number of times (Fig 3.3), to a minimum level of 1. For example, if the Gain was set at 4 (indicated by a sequence of four flashes of the Nav LED and four beeps), and the Gain needed to be increased to 7, pressing the Starboard key three times would adjust the Gain accordingly. The Nav LED would then flash seven times and seven beeps would be heard. To enter the Gain setting selected and exit to normal operation, press. 3.2 Seastate In a rough sea, more variations in heading will be detected by the pilot due to the heavy seas yawing the boat. The pilot would then be overworked, causing unnecessary strain on the unit and excessive drain on the batteries. All Navico Yachtpilots continuously monitor corrections applied to the rudder over the course of a voyage, and allow a dead band within which the boat can go off course without corrections being made (Fig 3.4). The dead band is automatically set and updated by the Yachtpilot to give the best compromise between course holding and battery consumption. 3.3 Autotrim To compensate for changing conditions, a rudder bias (sometimes known as rudder trim) is applied in order to steer a straight course. The amount of this rudder bias varies according to factors such as wind strength, boat speed, and trim tab setting. If this was not done then the boat would tend to veer off course. The Yachtpilot continuously monitors the average course error and applies a bias to the rudder to compensate until the optimum condition is reached. This bias is applied gradually, so not to upset the normal performance of the Yachtpilot. Thus, it may take up to a minute or so to fully compensate after a major course change. Once optimum trim is reached, the pilot will still monitor for changes in the prevailing conditions and update the trim accordingly. D E A D Average Course Fig Decreasing Gain level B A N D Fig Seastate deadband º

12 BATT NMEA YC500 YHS500 YLF500 DRIVE 4 Installation 4.1 Drive Installation For the Yachtpilot to operate efficiently, the YLA500 linear drive unit supplied must be installed correctly to allow maximum thrust at all rudder angles. It is usually preferable to connect the drive unit to the rudder stock via an independent tiller arm. Both Edson and Whitlock offer standard fittings for this purpose, although in certain cases, it may be possible to couple the pushrod to the same tiller arm or rudder quadrant used by the main steering linkage. Note that the linear drive system can exert a maximum thrust of over 300kg. If there is any doubt about the strength of the existing tiller arm or quadrant then the steering manufacturers must be consulted. It is important to ensure that the rudder at full lock is limited by the vessel s rudder stops rather than the end stops of the drive unit, otherwise damage to the drive unit could result when steering manually. The Yachtpilot system includes as standard the following drive fixing components - 114mm (4.56 in) 38mm (1.5 in) 114mm (4.56 in) 188mm (7.4 in) Components supplied - M8 x 50mm A4 hex head bolts x 4 M8 stainless steel washers x 4 M8 stainless steel nylock nuts x 4 Tillerbolt x 1 M12 stainless steel nylock nut x 1 M12 stainless steel washer x 2 S8 retaining clip x 1 Reservoir cap with breather x 1 464mm (18.3 in) Mid Stroke 564mm (22.2 in) Max 364mm (14.3in) Min 75mm sq (3.0 in) 100mm sq (4.0 in) 219mm (8.76 in) max 228mm (9.12 in) 73mm (2.92 in) Fig YLA500 mounting dimensions 4.8 Interfacing via NMEA The Yachtpilot includes an inbuilt NMEA0183 interface, which enables GPS, Decca, Loran etc receivers and windvanes to be connected directly to it. This allows the Steer To Wind and NavLock (Steer to GPS) functions to be used in addition to the standard Steer To Compass mode. To interface with the Yachtpilot, the NMEA OUT connections of the external equipment should be wired to the respective NMEA IN Data and Common (COM) terminals of the Yachtpilot course computer (Fig 4.15). Notes - 1. Some manufacturers may refer to the NMEA out connections as NMEA OUT + and respectively. 2. Certain equipment may also have connections marked NMEA IN. Do not use these. 3. If the receiver does not have an NMEA OUT COM (or ) connection, the NMEA IN COM terminal of the course computer should be connected to ground via the BATT terminal (Fig 4.16). 4. While any NMEA0183 compatible navigational receivers and windvanes should interface with the Yachtpilot, Navico cannot guarantee operation with other manufacturer s equipment, as the NavLock and Steer To Wind functions are dependant on specific NMEA0183 sentences of the correct format being present (see section 6.3). Therefore it is vital that the relevant section in the external equipment s manual is read thoroughly before attempting to interface it with the Yachtpilot. If necessary, contact the manufacturer s technical support department or speak to a qualified technical dealer. 5. The receiver must be running an active route or waypoint for the NavLock function to operate. + + BATT NMEA YC500 YHS500 YLF500 DRIVE NMEA OUT DATA (+) + + NMEA OUT DATA (+) DATA COMM DATA COMM NMEA OUT COMMON ( ) BLUE YLA500 SOLENOID Fig Connecting using NMEA interface BLUE YLA500 SOLENOID Fig Connecting using NMEA interface : no Common ( ) wire

13 The tillerbolt is a quick release fixing used to link the actuator ram to the tiller/quadrant (Fig 4.2) and should always be used. The rudder of the vessel and the ram should be set to the mid position when installing, and the drive should be installed so that it is horizontal (i.e parallel to the movement of the tiller/quadrant). To obtain the maximum power and a smooth force across the actuator s full stroke, the YLA500 should be installed in accordance with Fig 4.3, rather than at right angles to the tiller/quadrant. The Offset O and the distance T is relative to the angle that the rudder can move through from the mid position to the rudder stops, and can be interpolated from the graph overleaf (Fig 4.4). + DATA COMM BATT NMEA YC500 YHS500 YLF500 DRIVE BLUE YLA500 SOLENOID When positioning the actuator, the tiller arm length value T is measured from the rudder axis to the optimum position of mounting the pushrod of the actuator. The offset O is measured from the rudder axis to the actuator pivot axis. This gives the optimum position to mount the actuator in relation to the tiller/quadrant. As an example, if the rudder angle is 30º, this will give a tiller arm length T of 190mm (7.6 in) and an offset O of 165mm (6.6 in). To 12v + DC To 0v NMEA0183 In To Control Unit YC500 To Compass Unit PHS500 To Feedback Unit YLF500 To YLA500 Power To YLA500 Solenoid NOTE - The rudder angle referred to here is the maximum angle from the mid position (i.e straight ahead) to the rudder stop, NOT from port lock to starboard lock. Tiller Arm Length 'T' Tiller/Quadrant Rudder Stop Rudder Axis Offset 'O' Mounting Axis Fig Tillerbolt Fig Course Computer connections YLA500 Fig YLA500 mounting offset

14 Distance in mm (inches) Rudder Angle (Mid Position to Rudder Stop) 38mm (1.5 in) Example Tiller Arm Length 'T' Offset 'O' Oil reservoir (must be vertical) Horizontal Fig Offset Graph Fig Mounting of Linear Actuator 73mm (2.92 in) 4.6 Fitting Course Computer YCP500 The ideal location for the course computer is in a moisture, heat and vibration free area, somewhere between the boat s power source and the drive unit to minimise power cable lengths. The course computer should be mounted vertically with the cooling fin uppermost, and be easily accessible once installed. The unit is held in place using three No.6 x 1 self tapping screws. To access the mounting holes, loosen the three screws holding the terminal bay cover in place, and remove the cover. Drill and countersink three pilot holes in the indicated positions if attaching to GRP (Fig 4.12). Use the three self tapping screws provided to fix the course computer to the bulkhead. 4.7 Electrical Installation It is important that the correct diameter cable is used to supply the 12v power to the Yachtpilot, depending on the length of run necessary (Fig 4.13). For this reason, it is recommended that the course computer is sited as close to the power supply and pump as possible. All components are wired directly to the course computer. The terminal bay is clearly labelled, and each terminal block has a specific cable channel to suit the correct thickness of cable (Fig overleaf). The YLF500 feedback unit, YC500 control unit and PHS500 compass are all connected to the course computer via three core cables (Red, Black, White). Each cable is connected to the marked terminal block in the course computer terminal bay. To ensure good connections, all wire ends should be tinned if the cables are shortened. Poor connections will adversely affect the performance of the pilot. The cables should be run away from existing cables which carry radio frequency or pulsed signals (1m / 3 Ft min distance is recommended). Each cable should then be led through the appropriate cable channel, which will hold the cables firmly in position when the terminal bay cover is replaced. Length of Cable Run + + Under 5M (16.6Ft) 5-10M (33.3Ft) DATA COMM BATT NMEA YC500 YHS500 YLF500 DRIVE YLA500 SOLENOID 106mm (4.2 in) Cross Section Area 2.5mm 2 4mm 2 47mm (1.9 in) BLUE Fig Mounting Course Computer Conductor Type 50/ /0.3 Fig Cable selection table 43mm (1.7 in) AWG 13 12

15 4.4 Fitting Control Unit YC500 The Yachtpilot control unit YC500 is held in place using a single bolt system, requiring only two holes to be drilled. It should be located where the helmsman can reach it easily, near to the steering position. Ensure that the location selected is appropriate - there should be at least 40mm (1.6 in) clearance behind the bulkhead to allow for the shaft and cable entry. Mark the centres of the two holes where the control unit is to be positioned with a centre punch, one 38mm (1.5in) vertically above the other. Drill a 25mm (1.0 in) hole at the top mark, and a 5mm (0.2in) hole at the lower mark. If drilling into GRP, it is recommended to use a low speed setting on the drill to avoid cracking or splitting the gelcoat. Pass the cable through the larger hole and through the large fixing nut. Tighten the nut onto the threaded shaft to fix the control unit into place (do not overtighten), ensuring that the locating peg fits correctly into the smaller hole (Fig 4.10). Check that the cable is not obstructed or kinked before connecting. 4.5 Fitting Compass Unit PHS500 The compass unit should be positioned as close to the centreline as possible (Fig 4.11), in one of four possible orientations (see section 5.2). If the boat is GRP or wooden hulled, the compass can be mounted below deck, but must be at least 1m away from any metallic objects such as stereo speakers, heating units etc. If the boat has a metal hull (this includes ferrocement), it will be necessary to mount the compass above decks on a mast or pole between one and two metres above deck. When mounting, ensure that the compass unit is facing directly forward and is horizontal. The compass unit can be screwed to a vertical bulkhead using the two No.6 x 3 / 4 self tapping screws provided. If screwing into GRP, it is recommended that pilot holes are drilled and countersunk properly, which will stop the gelcoat splitting when the screws are tightened. 38mm (1.5 in) c/l c/l 25mm (1.0 in) 67mm (2.7 in) 5mm (0.2 in) Fig Mounting control unit Fig Mounting compass unit The drive mounting foot can be mounted in any orientation, providing that the direction of the thrust is in the same plane as the arc of the tiller. Use the M8x50mm bolts, washers and nuts supplied to fix the actuator to a secure structure (Fig 4.5). Note that if the drive is mounted upside down, the oil reservoir should be orientated so that it is vertical. If adjustment is necessary use an 18mm A/F spanner to hold and slightly slacken off the swivel nut. Ensure that the correct nut is slackened (Fig 4.6). Rotate the oil reservoir to the vertical position and retighten the swivel nut. Once the reservoir is correctly orientated and the nut retightened, the reservoir cap fitted during transit must be replaced with the breather cap supplied, identifiable by the integral black plastic mesh. It is often necessary to strengthen existing structures to withstand the forces exerted by the drive. It is always better to overstrengthen than to inadequately support the actuator, which could result in damage to the vessel. This advice cannot be overstressed. Mark the mounting position for the tillerbolt ( T ) on the tiller/quadrant, drill a 12mm hole and fit the tillerbolt in place using the M12 washer and bolts supplied (Fig 4.7). The tillerbolt has a flattened section on the shaft that allows it to be tightened securely with a spanner. The rod end bearing on the drive ram can then be slid over the tillerbolt, and is held in place using the retaining clip (Fig 4.8). In an emergency, the actuator can be quickly disengaged by removing the retaining clip and knocking the ram upwards. NOTE - The YLA500 drive can be backdriven when the Yachtpilot is in Standby Mode, enabling the vessel to be manually steered without disengaging the ram from the tillerbolt. While manual steering is not possible when the drive is engaged (i.e when in Autopilot Mode), as a failsafe it is always disengaged when there is no power supply. Therefore, in a total power loss situation the helm can be hand steered without having to disengage the ram. Swivel nut Fig Adjusting reservoir bottle orientation Tillerbolt Tiller Arm/Quadrant T M12 Washer M12 Nylock Nut Fig Fitting tillerbolt Linear Linear Actuator Retaining Clip Actuator Washer Actuator Rod end Rose bearing Joint Fig Attaching drive ram to tiller/quadrant

16 4.2 Installation Checklist - YLA500 Please complete this checklist after installing the linear drive unit. 1. Is the drive suitable for the vessel / steering system? 2. Is the drive secured to a substantial structure on the vessel? 3. Has the drive been mounted in the midstroke position when rudder is amidships? 4. Has the correct tiller arm length (T) and offset length (O) been used for the vessel s rudder angle? Yes Yes Yes Yes No No No No 4.3 Linear Feedback Unit YLF500 The YLF500 is the linear feedback unit which measures the rudder angle. As this is critical to the efficient performance of the Yachtpilot, it is important that the YLF500 is properly installed with the maximum possible stroke - minimum 150mm (6.0in), otherwise it will not accurately read the rudder position, compromising the efficiency of the Yachtpilot. Fig Mounting saddles (x 2) The mounting saddles (Fig 4.8) allow the YLF500 to be mounted directly on the back of the drive unit (Fig 4.9). Ensure that both units are exactly in line and that the YLF500 is vertically above the YLA500. The saddles should be positioned so that the full stroke of the drive does not exceed the stroke of the feedback unit. When fully extended in the hard over position the feedback rod should still be at least 25mm (1.0 in) within the feedback body - if the hard over position extends the rod beyond its physical limit, the feedback body could be damaged when the rod is retracted. The saddles are held in position using the two adhesive pads and cable ties supplied. The feedback rod is attached directly to the tillerbolt fixing using the balljoint on the top of the tillerbolt. Turn the wheel hard over from lock to lock, checking that the YLF500 rod does not bend at any time - this means that the YLF500 is not exactly parallel to the drive and should be adjusted. Feedback Unit YLF Is the actuator arm securely fitted to the tiller/quadrant using the tillerbolt supplied? Yes No 6. Are the end stops of the steering system limiting the rudder movement rather than the drive unit end stops? Yes No Mounting Saddles Self Adhesive Pads 7. Has the reservoir cap fitted to the YLA500 drive during transit been replaced with the breather cap supplied? Yes No Linear Drive Unit YLA500 If the answer to any of these checks is NO then the drive has not been correctly installed, and the error should be rectified before proceeding. Cable Ties Fig YLF500 positioning

Autopilot setup. VRF (Virtual Rudder Feedback) calibration. Software setup NSS evo2 Installation Manual

Autopilot setup Verifying the autopilot connection When an AC12N, AC42N, or SG05 is connected to the NSS evo2 system, the NSS evo2 will automatically detect the autopilot and an Autopilot menu icon will

Autopilot setup Verifying the autopilot connection When an AC12N, AC42N, or SG05 is connected to the NSS evo2 system, the NSS evo2 will automatically detect the autopilot and an Autopilot menu icon will

OPERATION AND INSTALLATION MANUAL

AP46 Autopilot OPERATION AND INSTALLATION MANUAL www.tmq.com.au TMQ AP46 Autopilot Page 1 of 34 Ver1.0 07/03/2007 This page is Blank TMQ AP46 Autopilot Page 2 of 34 Ver1.0 07/03/2007 WARNING!...4 INTRODUCTION...5

AP46 Autopilot OPERATION AND INSTALLATION MANUAL www.tmq.com.au TMQ AP46 Autopilot Page 1 of 34 Ver1.0 07/03/2007 This page is Blank TMQ AP46 Autopilot Page 2 of 34 Ver1.0 07/03/2007 WARNING!...4 INTRODUCTION...5

MAXIMIZING YOUR PERFORMANCE AT SEA

MAXIMIZING YOUR PERFORMANCE AT SEA Instruction Manual M A N U A L Simrad TillerPilots TM TP10 & TP22 &TP32 Tillerpilots E04818 Issue 1.0 III Tillerpilots TP10/TP22/TP32 2005 Simrad Ltd The technical data,

MAXIMIZING YOUR PERFORMANCE AT SEA Instruction Manual M A N U A L Simrad TillerPilots TM TP10 & TP22 &TP32 Tillerpilots E04818 Issue 1.0 III Tillerpilots TP10/TP22/TP32 2005 Simrad Ltd The technical data,

frequently asked questions

Hydra Pilot Fault Codes What do the fault codes for the Hydra Pilot mean? Fault Cause FAULT 100 FAULT 101 FAULT 102 FAULT 103 FAULT 104 FAULT 105 FAULT 106 FAULT 108 FAULT 109 FAULT 110 FAULT 111 FAULT

Hydra Pilot Fault Codes What do the fault codes for the Hydra Pilot mean? Fault Cause FAULT 100 FAULT 101 FAULT 102 FAULT 103 FAULT 104 FAULT 105 FAULT 106 FAULT 108 FAULT 109 FAULT 110 FAULT 111 FAULT

REACTOR 40 MECHANICAL Configuration Guide

REACTOR 40 MECHANICAL Configuration Guide Important Safety Information WARNING See the Important Safety and Product Information guide in the product box for product warnings and other important information.

REACTOR 40 MECHANICAL Configuration Guide Important Safety Information WARNING See the Important Safety and Product Information guide in the product box for product warnings and other important information.

INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 SELECTING THE DISPLAY MODE 5 ABBREVIATIONS AND DEFINITIONS 17

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

USER MANUAL. Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK. Tel: (+44) Fax: (+44)

USER MANUAL Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK Tel: (+44) 01590 689699 Fax: (+44) 01590 610072 www.bandgservice.co.uk Brookes and Gatehouse Ltd. 2000 The copyright of this Manual is

USER MANUAL Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK Tel: (+44) 01590 689699 Fax: (+44) 01590 610072 www.bandgservice.co.uk Brookes and Gatehouse Ltd. 2000 The copyright of this Manual is

SP-110 Autopilot OPERATION

SP-110 Autopilot OPERATION www.si-tex.com Warning! WHEN USING THE AUTOPILOT AN ADEQUATE WATCH SHOULD BE MAINTAINED AT ALL TIMES. THE AUTOPILOT MUST BE PLACED IN MANUAL MODE WHEN EVER THE VESSEL IS STATIONARY

SP-110 Autopilot OPERATION www.si-tex.com Warning! WHEN USING THE AUTOPILOT AN ADEQUATE WATCH SHOULD BE MAINTAINED AT ALL TIMES. THE AUTOPILOT MUST BE PLACED IN MANUAL MODE WHEN EVER THE VESSEL IS STATIONARY

User s Guide. Leisure Pilots 715, 730 & 740. for. Issue 06 for use with version V3.00 software (or later) in the Pilot Computer

User s Guide for Leisure Pilots 715, 730 & 740 Issue 06 for use with version V3.00 software (or later) in the Pilot Computer Welcome... All of us at would like to welcome you to the reliable world of our

User s Guide for Leisure Pilots 715, 730 & 740 Issue 06 for use with version V3.00 software (or later) in the Pilot Computer Welcome... All of us at would like to welcome you to the reliable world of our

S1000+ / S2000+ Tiller Pilots. Owner s manual

S1000+ / S2000+ Tiller Pilots Owner s manual Chapter 1: Introduction Chapter 1: Introduction 1.1 Overview D5557-2 Your Raymarine tiller pilot is a totally self-contained autopilot designed for tiller steered

S1000+ / S2000+ Tiller Pilots Owner s manual Chapter 1: Introduction Chapter 1: Introduction 1.1 Overview D5557-2 Your Raymarine tiller pilot is a totally self-contained autopilot designed for tiller steered

ST1000 Plus & ST2000 Plus Tiller Pilots Owner s Handbook. Document number: Date: June 2001

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. ST1000 Plus & ST2000 Plus Tiller Pilots

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. ST1000 Plus & ST2000 Plus Tiller Pilots

CONTENTS STEER TO VANE MODE...

CONTENTS GENERAL INTRODUCTION TO B&G NETWORK... 2 INTRODUCTION TO NETWORK PILOT... 3 SWITCHING THE NETWORK PILOT ON... 3 NETWORK PILOT DISPLAY UNIT... 4 NETWORK PILOT HAND-HELD CONTROLLER... 5 JOYSTICK

CONTENTS GENERAL INTRODUCTION TO B&G NETWORK... 2 INTRODUCTION TO NETWORK PILOT... 3 SWITCHING THE NETWORK PILOT ON... 3 NETWORK PILOT DISPLAY UNIT... 4 NETWORK PILOT HAND-HELD CONTROLLER... 5 JOYSTICK

S1000+ / S2000+ Tiller Pilots

S1000+ / S2000+ Tiller Pilots Owner s handbook English Date: 12-2013 Document number: 81130-7-EN 2013 Raymarine UK Limited 1 Contents Contents... 1 Chapter 1: Introduction...3 1.1 Overview... 3 1.2 Specifications...

S1000+ / S2000+ Tiller Pilots Owner s handbook English Date: 12-2013 Document number: 81130-7-EN 2013 Raymarine UK Limited 1 Contents Contents... 1 Chapter 1: Introduction...3 1.1 Overview... 3 1.2 Specifications...

PART 5 - OPTIONS CONTENTS 5.1 SYSTEM EXPANSION 5-3

PART 5 - OPTIONS CONTENTS Para Page 5.1 SYSTEM EXPANSION 5-3 5.2 SENSORS 5-3 5.2.1 Trim Angle Sensor 5-3 5.2.2 Mast Rotation Sensor 5-3 5.2.3 Heel Angle Sensor 5-3 5.2.4 Barometric Pressure Sensor 5-3

PART 5 - OPTIONS CONTENTS Para Page 5.1 SYSTEM EXPANSION 5-3 5.2 SENSORS 5-3 5.2.1 Trim Angle Sensor 5-3 5.2.2 Mast Rotation Sensor 5-3 5.2.3 Heel Angle Sensor 5-3 5.2.4 Barometric Pressure Sensor 5-3

Pilot 3380 A U T O P I L O T. Operation Manual NAVMAN

Pilot 3380 A U T O P I L O T Operation Manual w w w. n a v m a n. c o m NAVMAN FCC Statement Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

Pilot 3380 A U T O P I L O T Operation Manual w w w. n a v m a n. c o m NAVMAN FCC Statement Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

Simrad yachting catalog 2007

26 AUTOSTEERING Electronic intelligence combined with powerful and reliable designs make sure you enjoy boating even more. 27 Tillerpilots Enjoy silence when sailing SIMRAD TP SERIES REMOTE COMMANDER High

26 AUTOSTEERING Electronic intelligence combined with powerful and reliable designs make sure you enjoy boating even more. 27 Tillerpilots Enjoy silence when sailing SIMRAD TP SERIES REMOTE COMMANDER High

TOP BLEED Position for SeaTalk 2 colour logo ST 30. COMPASS Operation and Installation

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. TOP BLEED Position for SeaTalk 2 colour

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. TOP BLEED Position for SeaTalk 2 colour

Explorer AP380 Autopilot Installation and Operation Manual

Explorer AP380 Autopilot Installation and Operation Manual www.northstarnav.com IMPORTANT SAFETY INFORMATION Please read carefully before installation and use. DANGER! WARNING! CAUTION CAUTION This is

Explorer AP380 Autopilot Installation and Operation Manual www.northstarnav.com IMPORTANT SAFETY INFORMATION Please read carefully before installation and use. DANGER! WARNING! CAUTION CAUTION This is

AP55 Display OPERATION AND INSTALLATION MANUAL.

AP55 Display OPERATION AND INSTALLATION MANUAL www.tmq.com.au Index INDEX... 2 INTRODUCTION... 3 System configuration... 3 System Block Diagram... 4 Definition of Terms... 6 Overview of Operation... 8

AP55 Display OPERATION AND INSTALLATION MANUAL www.tmq.com.au Index INDEX... 2 INTRODUCTION... 3 System configuration... 3 System Block Diagram... 4 Definition of Terms... 6 Overview of Operation... 8

ST600R Autopilot Control Unit Owner s Handbook. Document number: Date: May 2001

ST600R Autopilot Control Unit Owner s Handbook Document number: 81134-3 Date: May 2001 -10-1 +10 +1 Preface i stdby auto track Raymarine, as part of its commitment to continuous improvement and updating,

ST600R Autopilot Control Unit Owner s Handbook Document number: 81134-3 Date: May 2001 -10-1 +10 +1 Preface i stdby auto track Raymarine, as part of its commitment to continuous improvement and updating,

GHC 20. Owner s Manual

GHC 20 Owner s Manual 2013 Garmin Ltd. or its subsidiaries All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin

GHC 20 Owner s Manual 2013 Garmin Ltd. or its subsidiaries All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin

ST7000 Plus Autopilot Control Unit Owner s Handbook

ST7000 Plus Autopilot Control Unit Owner s Handbook Document number: 81118_1 Date: 20 January 1999 Preface i Raytheon Electronics, as part of its commitment to continuous improvement and updating, reserve

ST7000 Plus Autopilot Control Unit Owner s Handbook Document number: 81118_1 Date: 20 January 1999 Preface i Raytheon Electronics, as part of its commitment to continuous improvement and updating, reserve

SmartPilot X-Series. Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems

SmartPilot X-Series Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems Document reference: 81307-1 Date: December 2007 SeaTalk is a registered trademark of Raymarine Ltd.

SmartPilot X-Series Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems Document reference: 81307-1 Date: December 2007 SeaTalk is a registered trademark of Raymarine Ltd.

S100 Controller. User guide. English Date: Document number: EN 2006 Raymarine UK Limited

S100 Controller User guide English Date: 06-2006 Document number: 81242-4-EN 2006 Raymarine UK Limited 1 - Getting Started Changing the Controller batteries... 5 The S100 Autopilot Controller... 6 How

S100 Controller User guide English Date: 06-2006 Document number: 81242-4-EN 2006 Raymarine UK Limited 1 - Getting Started Changing the Controller batteries... 5 The S100 Autopilot Controller... 6 How

˵à Êé OPERATOR'S MANUAL. Autopilot

KAP-833 KAP833 ˵à Êé OPERATOR'S MANUAL Autopilot Warning! Automatic pilots are designed to be a navigational aid. As an automatic steering aid, an autopilot can alleviate the boredom of hand steering.

KAP-833 KAP833 ˵à Êé OPERATOR'S MANUAL Autopilot Warning! Automatic pilots are designed to be a navigational aid. As an automatic steering aid, an autopilot can alleviate the boredom of hand steering.

SmartPilot Series. Operating Guide. Document reference: Date: October 2006

SmartPilot Series S1WheelPilot S1 TillerPilot Operating Guide Document reference: 81283-1 Date: October 2006 Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks

SmartPilot Series S1WheelPilot S1 TillerPilot Operating Guide Document reference: 81283-1 Date: October 2006 Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks

Installation, Compensation and Maintenance Instructions for. RITCHIE Compasses. Made In U.S.A

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

ST70 Autopilot Controller User Reference Guide

ST70 Autopilot Controller User Reference Guide Document reference: 81288-2 Date: May 2010 ii iii Contents Preface Warnings and cautions WARNING: Product installation & operation This equipment must be

ST70 Autopilot Controller User Reference Guide Document reference: 81288-2 Date: May 2010 ii iii Contents Preface Warnings and cautions WARNING: Product installation & operation This equipment must be

GHC 20 Owner s Manual

GHC 20 Owner s Manual Introduction See the Important Safety and Product Information guide in the product box for product warnings and other important information. You are responsible for the safe and prudent

GHC 20 Owner s Manual Introduction See the Important Safety and Product Information guide in the product box for product warnings and other important information. You are responsible for the safe and prudent

SmartPilot X-5. Tiller & GP Tiller Operating Guide. Document reference: Date: October 2007

SmartPilot X-5 Tiller & GP Tiller Operating Guide Document reference: 81303-1 Date: October 2007 SeaTalk is a registered trademark of Raymarine Ltd. Raymarine, SeaTalk ng, SmartPilot, AutoLearn, AutoRelease,

SmartPilot X-5 Tiller & GP Tiller Operating Guide Document reference: 81303-1 Date: October 2007 SeaTalk is a registered trademark of Raymarine Ltd. Raymarine, SeaTalk ng, SmartPilot, AutoLearn, AutoRelease,

Manual Leveling Control Installation/Operation

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

ST5000+ Sterndrive & Hydraulic Autopilots. Owner s handbook. English Date: Document number: EN 2006 Raymarine UK Limited

ST5000+ Sterndrive & Hydraulic Autopilots Owner s handbook English Date: 09-2006 Document number: 81132-7-EN 2006 Raymarine UK Limited Preface i Hydraulic Sterndrive Rudder Reference Unit (Optional for

ST5000+ Sterndrive & Hydraulic Autopilots Owner s handbook English Date: 09-2006 Document number: 81132-7-EN 2006 Raymarine UK Limited Preface i Hydraulic Sterndrive Rudder Reference Unit (Optional for

INSTALLING THE ECHO SOUNDER TRANSDUCER CHANGING THE OPERATING CONFIGURATION

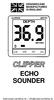

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

81270_1.book Page i Wednesday, November 9, :33 PM. ST7002 SmartPilot Controller Operating Guide

81270_1.book Page i Wednesday, November 9, 2005 2:33 PM ST7002 SmartPilot Controller Operating Guide Document reference: 81270-1 Date: December 2005 81270_1.book Page ii Wednesday, November 9, 2005 2:33

81270_1.book Page i Wednesday, November 9, 2005 2:33 PM ST7002 SmartPilot Controller Operating Guide Document reference: 81270-1 Date: December 2005 81270_1.book Page ii Wednesday, November 9, 2005 2:33

WIND CLIPPER KTS ILLUM SCALE INC DEC CLIPPER WIND SYSTEM

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

ST4000+ Wheel & Tiller Autopilots Owner s Handbook. Document number: Date: August 2001

ST4000+ Wheel & Tiller Autopilots Owner s Handbook Document number: 81131-6 Date: August 2001 ii ST4000+ Wheel & Tiller Autopilots: Owner s Handbook Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and

ST4000+ Wheel & Tiller Autopilots Owner s Handbook Document number: 81131-6 Date: August 2001 ii ST4000+ Wheel & Tiller Autopilots: Owner s Handbook Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and

SmartPilot Series. Commissioning Guide. Document reference: Date: Sept 2006

SmartPilot Series S1WheelPilot S1 TillerPilot Commissioning Guide Document reference: 81282-1 Date: Sept 2006 Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks

SmartPilot Series S1WheelPilot S1 TillerPilot Commissioning Guide Document reference: 81282-1 Date: Sept 2006 Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot are registered trademarks

Steer to Wind angle, Wind Mode, when connected to the h1000 Wind Interface

h1000 pilot introduction overview Congratulations on your purchase of the h1000 Pilot from B&G. The h1000 Pilot is the latest in autopilots from B&G and represents B&G s commitment to providing our customers

h1000 pilot introduction overview Congratulations on your purchase of the h1000 Pilot from B&G. The h1000 Pilot is the latest in autopilots from B&G and represents B&G s commitment to providing our customers

ST7001 Smartpilot Controller Operating Guide

ST7001 Smartpilot Controller Operating Guide Document number: 81225-1 Date: July 2003 ii ST7001+ Smartpilot Controller Operating Guide Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot

ST7001 Smartpilot Controller Operating Guide Document number: 81225-1 Date: July 2003 ii ST7001+ Smartpilot Controller Operating Guide Autohelm, HSB (High Speed Bus), SailPilot, SeaTalk and SportPilot

TS-202 FFU Lever Remote Part Number & Operation & Installation Instructions Version 2.1

R TS-202 FFU Lever Remote Part Number 20310020 & 20310029 Operation & Installation Instructions Version 2.1 ComNav Marine Ltd. 15 13511 Crestwood Place. Richmond, B.C. Canada. V6V-2G1 Document PN 29010046

R TS-202 FFU Lever Remote Part Number 20310020 & 20310029 Operation & Installation Instructions Version 2.1 ComNav Marine Ltd. 15 13511 Crestwood Place. Richmond, B.C. Canada. V6V-2G1 Document PN 29010046

81131_8.book Page i Thursday, October 7, :03 AM. ST4000+ Wheel & Tiller Autopilots Owner s Handbook

81131_8.book Page i Thursday, October 7, 2004 11:03 AM ST4000+ Wheel & Tiller Autopilots Owner s Handbook Document number: 81131-8 Date: November 2004 81131_8.book Page ii Thursday, October 7, 2004 11:03

81131_8.book Page i Thursday, October 7, 2004 11:03 AM ST4000+ Wheel & Tiller Autopilots Owner s Handbook Document number: 81131-8 Date: November 2004 81131_8.book Page ii Thursday, October 7, 2004 11:03

SC 110 Autopilot Installation and Operations Manual _A

SC 110 Autopilot Installation and Operations Manual 531760-3_A Thank You Thank you for choosing Humminbird, the #1 name in Fishfinders. Humminbird has built its reputation by designing and manufacturing

SC 110 Autopilot Installation and Operations Manual 531760-3_A Thank You Thank you for choosing Humminbird, the #1 name in Fishfinders. Humminbird has built its reputation by designing and manufacturing

RAI-M series RUDDER ANGLE INDICATOR SYSTEM

RUDDER ANGLE INDICATOR SYSTEM RAI-M series SEAFIRST ENGINEERING CO 45-16, Ga Um Dong, Chang Won, Kyong Nam Korea Tel : 82 55 267 1645 Fax ; 82 55 266 1646 http://www.seafirst.co.kr GENERAL Seafirst Rudder

RUDDER ANGLE INDICATOR SYSTEM RAI-M series SEAFIRST ENGINEERING CO 45-16, Ga Um Dong, Chang Won, Kyong Nam Korea Tel : 82 55 267 1645 Fax ; 82 55 266 1646 http://www.seafirst.co.kr GENERAL Seafirst Rudder

Tentec. Instruction Document. Mini Air Driven Pump Unit Model: HTT.627X Series. Part Identifier

Tentec Page 1 w w w. t e n t e c. n e t Instruction Document Mini Air Driven Pump Unit Model: HTT.627X Series HTT.6271 Maximum Working Pressure = 1500bar (21750 psi) HTT.6272 Maximum Working Pressure =

Tentec Page 1 w w w. t e n t e c. n e t Instruction Document Mini Air Driven Pump Unit Model: HTT.627X Series HTT.6271 Maximum Working Pressure = 1500bar (21750 psi) HTT.6272 Maximum Working Pressure =

h2000 Autopilot User Manual

h2000 Autopilot User Manual! WANING The use of solvent based or chemical cleaners on the Pilot Displays will result in damage and invalidate your warranty. Premier Way Abbey Park, omsey Hampshire, SO51

h2000 Autopilot User Manual! WANING The use of solvent based or chemical cleaners on the Pilot Displays will result in damage and invalidate your warranty. Premier Way Abbey Park, omsey Hampshire, SO51

GNX 20/21. Owner s Manual

GNX 20/21 Owner s Manual Table of Contents Introduction...1 Device Overview... 1 Using the Race Timer... 1 Profiles... 1 Selecting a Profile... 1 Restoring Profiles to their Default Settings... 1 Instrument

GNX 20/21 Owner s Manual Table of Contents Introduction...1 Device Overview... 1 Using the Race Timer... 1 Profiles... 1 Selecting a Profile... 1 Restoring Profiles to their Default Settings... 1 Instrument

Sail Racing Instruments. Aspect 40

Sail Racing Instruments www.nexusmarine.se Presentation Nexus Marine is a leading manufacturer of navigation instrumentation for racing and cruising yachts. Nexus brings with it seventy years of experience

Sail Racing Instruments www.nexusmarine.se Presentation Nexus Marine is a leading manufacturer of navigation instrumentation for racing and cruising yachts. Nexus brings with it seventy years of experience

RESOLUTION MSC.94(72) (adopted on 22 May 2000) PERFORMANCE STANDARDS FOR NIGHT VISION EQUIPMENT FOR HIGH-SPEED CRAFT (HSC)

MSC 72/23/Add.1 RESOLUTION MSC.94(72) EQUIPMENT FOR HIGH-SPEED CRAFT (HSC) THE MARITIME SAFETY COMMITTEE, RECALLING Article 28(b) of the Convention on the International Maritime Organization concerning

MSC 72/23/Add.1 RESOLUTION MSC.94(72) EQUIPMENT FOR HIGH-SPEED CRAFT (HSC) THE MARITIME SAFETY COMMITTEE, RECALLING Article 28(b) of the Convention on the International Maritime Organization concerning

Raymarine s Autohelm Series. An extra crew member at your command.

42 43 Raymarine s Autohelm Series. An extra crew member at your command. It s a beautiful day, the sun s out, the sea s blue and you re underway - what a great opportunity for Starting life as Nautech/Autohelm

42 43 Raymarine s Autohelm Series. An extra crew member at your command. It s a beautiful day, the sun s out, the sea s blue and you re underway - what a great opportunity for Starting life as Nautech/Autohelm

An innovative windvane pendulum system for sailing boats with outboard rudders.

An innovative windvane pendulum system for sailing boats with outboard rudders. Jan Alkema 26 sept. 2005 figure 8. The oar blade retracted figure 7. The oar blade in the water Preface On boats with outboard

An innovative windvane pendulum system for sailing boats with outboard rudders. Jan Alkema 26 sept. 2005 figure 8. The oar blade retracted figure 7. The oar blade in the water Preface On boats with outboard

UBEC 1AT. AUTO TANK Fill System Installation, Operation, & Setup Instructions

Document Number: XE-ATA5PM-R1A UBEC 1AT AUTO TANK Fill System 08899155 Installation, Operation, & Setup Instructions Rev170906-EB-FRC PHYSICAL: 1302 WEST BEARDSLEY AVE ELKHART, IN 46514 WWW.ELKHARTBRASS.COM

Document Number: XE-ATA5PM-R1A UBEC 1AT AUTO TANK Fill System 08899155 Installation, Operation, & Setup Instructions Rev170906-EB-FRC PHYSICAL: 1302 WEST BEARDSLEY AVE ELKHART, IN 46514 WWW.ELKHARTBRASS.COM

GV Standard X-Vent. Setup, Commissioning & Installation Guide

GV Standard X-Vent Setup, Commissioning & Installation Guide Technical experts in the design, manufacture and supply of precision engineered, architectural rooflights for residential and commercial buildings.

GV Standard X-Vent Setup, Commissioning & Installation Guide Technical experts in the design, manufacture and supply of precision engineered, architectural rooflights for residential and commercial buildings.

Depth sensor. Product reference : REV 1. USER GUIDE and INSTALLATION GUIDE. nke Sailing competition

Depth sensor Product reference : 90-60-456 REV 1 USER GUIDE and INSTALLATION GUIDE nke Sailing competition Z.I. Kerandré Rue Gutenberg 56700 HENNEBONT- FRANCE http://www.nke.fr After sale service n 33

Depth sensor Product reference : 90-60-456 REV 1 USER GUIDE and INSTALLATION GUIDE nke Sailing competition Z.I. Kerandré Rue Gutenberg 56700 HENNEBONT- FRANCE http://www.nke.fr After sale service n 33

- Course Processor R

http://nex / /Autopilot/dig_auto.tif Autopilot - Course Processor R-1600 - Installation and Operation Manual AUTOPILOT 8-1 AUTOPILOT This manual is written for NX2 Autopilot version 1.00 Edition: May 2012

http://nex / /Autopilot/dig_auto.tif Autopilot - Course Processor R-1600 - Installation and Operation Manual AUTOPILOT 8-1 AUTOPILOT This manual is written for NX2 Autopilot version 1.00 Edition: May 2012

1420 Autopilot System. Installation & Operation Manual

1420 Autopilot System Installation & Operation Manual WELCOME Congratulations on your purchase of a ComNav Marine 1420 Autopilot System! At ComNav, we are dedicated to reliability & quality in all our

1420 Autopilot System Installation & Operation Manual WELCOME Congratulations on your purchase of a ComNav Marine 1420 Autopilot System! At ComNav, we are dedicated to reliability & quality in all our

400C & 450C DUAL PERFORMANCE VALUE PACKS

(Chrome) PART NO. 40013 (Silver) PART NO. 45012 (Chrome) PART NO. 45013 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before

(Chrome) PART NO. 40013 (Silver) PART NO. 45012 (Chrome) PART NO. 45013 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before

GNX 20/21. Owner s Manual

GNX 20/21 Owner s Manual March 2016 190-01659-00_0C All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin reserves

GNX 20/21 Owner s Manual March 2016 190-01659-00_0C All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin reserves

INSTALLATION MANUAL 2001 AUTOPILOT

INSTALLATION MANUAL 2001 AUTOPILOT WARRANTY NOTICE Prior to the installation and/or operation of the Equipment, ensure that you read, understand and accept the conditions of the warranties as detailed

INSTALLATION MANUAL 2001 AUTOPILOT WARRANTY NOTICE Prior to the installation and/or operation of the Equipment, ensure that you read, understand and accept the conditions of the warranties as detailed

444C DUAL PERFORMANCE VALUE PACK

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

2. USER INSTRUCTION. Table of contents: Pg.1/14 N:\FAP-2000: LWP

Pg.1/14 2. USER INSTRUCTION. Table of contents: 2.1 SHORT PANEL DESCRIPTION...... Pg.2 2.2 AUTOPILOT TAKE-OVER & MODE SELECTION....... Pg.3 2.3 AUTOPILOT FUNCTIONS....... Pg.3 2.4 THE SPECIAL FUNCTION

Pg.1/14 2. USER INSTRUCTION. Table of contents: 2.1 SHORT PANEL DESCRIPTION...... Pg.2 2.2 AUTOPILOT TAKE-OVER & MODE SELECTION....... Pg.3 2.3 AUTOPILOT FUNCTIONS....... Pg.3 2.4 THE SPECIAL FUNCTION

A4 Operation Manual. Fig.1-1 Controller Socket Diagram

A4 Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

A4 Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

Pressure Dump Valve Service Kit for Series 2300 Units

Instruction Sheet Pressure Dump Valve Service Kit for Series 00 Units. Overview The Nordson pressure dump valve is used to relieve hydraulic pressure instantly in Series 00 applicator tanks when the unit

Instruction Sheet Pressure Dump Valve Service Kit for Series 00 Units. Overview The Nordson pressure dump valve is used to relieve hydraulic pressure instantly in Series 00 applicator tanks when the unit

GNX 20/21 Owner s Manual

GNX 20/21 Owner s Manual February 2014 190-01659-00_0B Printed in Taiwan All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of

GNX 20/21 Owner s Manual February 2014 190-01659-00_0B Printed in Taiwan All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of

Model 130M Pneumatic Controller

Instruction MI 017-450 May 1978 Model 130M Pneumatic Controller Installation and Operation Manual Control Unit Controller Model 130M Controller is a pneumatic, shelf-mounted instrument with a separate

Instruction MI 017-450 May 1978 Model 130M Pneumatic Controller Installation and Operation Manual Control Unit Controller Model 130M Controller is a pneumatic, shelf-mounted instrument with a separate

200 PSI COMPRESSORS - MODEL NUMBERS

200 PSI COMPRESSORS - MODEL NUMBERS 380C AIR COMPRESSOR KIT PART NO. 38033 480C AIR COMPRESSOR KIT PART NO. 48043 380C 480C IMPORTANT: It is essential that you and any other operator of this product read

200 PSI COMPRESSORS - MODEL NUMBERS 380C AIR COMPRESSOR KIT PART NO. 38033 480C AIR COMPRESSOR KIT PART NO. 48043 380C 480C IMPORTANT: It is essential that you and any other operator of this product read

A4s Operation Manual

A4s Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

A4s Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual Man 188 1.1.0 06/08/2014 Chris Rasmussen Philip Day Chris Rasmussen Manual No. Revision Date Originator Checked Authorised for Issue User

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual Man 188 1.1.0 06/08/2014 Chris Rasmussen Philip Day Chris Rasmussen Manual No. Revision Date Originator Checked Authorised for Issue User

Section V Sailing off the wind

Section V Sailing off the wind 1 Sail shapes and flow patterns - off the wind a) Principles When reaching, it is maximum thrust which is important, and here the leech ribbons come into their own. Fig.43a

Section V Sailing off the wind 1 Sail shapes and flow patterns - off the wind a) Principles When reaching, it is maximum thrust which is important, and here the leech ribbons come into their own. Fig.43a

SmartPilot X5 Sport Installation & Setup Guide

SmartPilot X5 Sport Installation & Setup Guide Document reference: 87076-3 Date: August 2009 www.raymarine.com Autohelm, HSB, RayTech Navigator, Sail Pilot, SeaTalk and Sportpilot are UK registered trademarks

SmartPilot X5 Sport Installation & Setup Guide Document reference: 87076-3 Date: August 2009 www.raymarine.com Autohelm, HSB, RayTech Navigator, Sail Pilot, SeaTalk and Sportpilot are UK registered trademarks

ST60 Depth Instrument Owner s Handbook. Document number: Date: 1 April 2004

ST60 Depth Instrument Owner s Handbook Document number: 81038-4 Date: 1 April 2004 Raymarine, ST60 and SeaTalk are trademarks of Raymarine Limited Handbook contents copyright Raymarine Limited 2004 Preface

ST60 Depth Instrument Owner s Handbook Document number: 81038-4 Date: 1 April 2004 Raymarine, ST60 and SeaTalk are trademarks of Raymarine Limited Handbook contents copyright Raymarine Limited 2004 Preface

OPERATING INFORMATION

www.bandg.com CONTENTS B&G Notification... 7 Liability and Safety Warnings... 8 About B&G... 9 About this Handbook... 9 SYSTEM INTRODUCTION H3000 System Example... 11 H3000 Pilot ACP... 12 Graphical Pilot

www.bandg.com CONTENTS B&G Notification... 7 Liability and Safety Warnings... 8 About B&G... 9 About this Handbook... 9 SYSTEM INTRODUCTION H3000 System Example... 11 H3000 Pilot ACP... 12 Graphical Pilot

100C Air Compressor Kit