OPERATION AND INSTALLATION MANUAL

|

|

|

- Crystal Roberts

- 5 years ago

- Views:

Transcription

1 AP46 Autopilot OPERATION AND INSTALLATION MANUAL TMQ AP46 Autopilot Page 1 of 34 Ver1.0 07/03/2007

2 This page is Blank TMQ AP46 Autopilot Page 2 of 34 Ver1.0 07/03/2007

3 WARNING!...4 INTRODUCTION...5 BLOCK DIAGRAM OF FULL SYSTEM... 6 DEFINITION OF TERMS...7 OVERVIEW OF OPERATION...7 TURNING THE UNIT ON / OFF...9 MANUAL MODE... 9 AUTO MODE...9 GPS MODE...10 Engaging GPS Mode:...10 DISENGAGING GPS MODE: SETTING UP YOUR GPS UNIT:...11 JOG MODE...13 RUDDER SENSITIVITY / RATIO BACKLIGHTING RUDDER ANGLE INDICATOR INITIAL SETTINGS...17 MOTOR DIRECTION...17 RUDDER LIMITS...17 RESET RUDDER LIMITS...18 COMPASS CALIBRATION...18 ALARMS...19 A NUMBER OF CONDITIONS WILL CAUSE ALARMS TO SOUND AND AN ALARM MESSAGE TO FLASH ON THE DISPLAY...19 OFF COURSE ALARM GPS ALARM INSTALLATION OF AP46 HEAD UNIT INSTALLATION OF COMPASS...20 AP46 HEAD WIRING DIAGRAM...24 INSTALLATION OF RUDDER FEEDBACK RUDDER FEEDBACK INSTALLATION DIAGRAM Rudder Feedback Installation Notes RFU WIRING:...27 RUDDER FEEDBACK / GPS WIRING DIAGRAMS...27 Figure 1 Rudder Feedback / GPS Connection Diagram...27 GPS CONNECTION...28 REVERSING PUMP CONNECTION TESTING PROCEDURE...30 TMQ AP46 Autopilot Page 3 of 34 Ver1.0 07/03/2007

4 TROUBLE SHOOTING...31 Hydraulic Drives and Pump Units TECHNICIAN SET UP PROCEDURE Warning! Automatic pilots are designed to be a navigational aid. As an automatic steering aid, an autopilot can alleviate the boredom of hand steering. This allows the operator of the vessel time to attend to other duties, keep a more accurate check of navigation duties or just relax and enjoy the trip. HOWEVER, THE AUTOPILOT SHOULD NOT BE LEFT SOLELY IN CHARGE OF THE VESSEL AND AN ADEQUATE WATCH SHOULD BE MAINTAINED AT ALL TIMES. IT IS STRONGLY RECOMMENDED THAT THE AUTOPILOT SHOULD NOT BE USED WHILE NAVIGATING IN RESTRICTED WATERWAYS AS WATER CURRENTS, WIND CHANGES OR RADIO TRANSMITTER INTERFERENCE CAN ENDANGER YOUR OWN OR OTHER VESSELS. TMQ AP46 Autopilot Page 4 of 34 Ver1.0 07/03/2007

5 Introduction Congratulations on your wise choice and purchase of the TMQ AP46 Autopilot system. We are sure that you will enjoy the benefits that it offers. AP46 Autopilot System The AP46 Autopilot system comprises the following units: - Essential Electronics: AP46 display and control head. Rudder feedback unit. Elproma Compass ECS1 Drive unit, for example - Hydraulic system with solenoid valves. - Reversing hydraulic pump system. TMQ AP46 Autopilot Page 5 of 34 Ver1.0 07/03/2007

6 Block Diagram of full system The AP46 head provides full control of the autopilot, indicating in different modes heading, course to steer and rudder angle. It requires a supply voltage of 12 volts DC. The Rudder Feedback Unit (RFU) must be attached to the steering tiller device in such a way that it can accurately measure the movement of the ship s rudder (see Rudder Feedback Installation diagram page 25). The RFU must also be electrically connected to the AP46 Head unit. Rudder actuator system: this system provides the physical movement to the rudder responding to the direction control signals provided by AP46 system. A rudder actuator system comprises the following: - Hydraulic Ram - controlled by either: - 1. Reversing motor and pump unit, connected into an existing hydraulic steering system; 2. Solenoid valves connected into an existing power steering system; or, 3. Solenoid valves connected to a continuous running motor and pump unit. TMQ AP46 Autopilot Page 6 of 34 Ver1.0 07/03/2007

7 Definition of Terms AP46 Display: The Operation unit, with LCD Display and push buttons. Rudder Feedback Unit (RFU): This provides the required rudder position information for steering control. Heading: This is the magnetic heading of the vessel at the current time. Course-to-steer: The magnetic heading which the autopilot is attempting to maintain. Overview of Operation MANUAL Mode: H*** The autopilot display unit shows the current magnetic heading. The vessel is under manual steering control; the autopilot will not apply any steering control. AUTO Mode: A*** TMQ AP46 Autopilot Page 7 of 34 Ver1.0 07/03/2007

8 The autopilot will maintain your vessel on the magnetic course indicated. This course can be set or altered from the display unit. GPS Mode: A*** When receiving information from a GPS unit, the autopilot can steer a vessel to a precise latitude and longitude (waypoint), or through a sequence of latitudes and longitudes (route). RUDDER and RESPONSE Settings: These customise the AP46 Autopilot for your vessel s steering. They may also be used to adjust for varying sea conditions. Rudder Angle Displays: The AP46 display unit LCD can be set to display the rudder angle as a numeric number. Backlighting: When using the autopilot at night, the backlighting can be turned on. Jog Mode: When the autopilot is in manual mode, the port or starboard buttons may be pressed and the steering will be driven in that direction. TMQ AP46 Autopilot Page 8 of 34 Ver1.0 07/03/2007

9 Turning the unit ON / OFF The power to the AP46 unit should be connected via a suitable 15 amp circuit breaker. MANUAL Mode In this mode The display screen shows H*** ; (***) being the current vessel magnetic heading in degrees. No steering control is generated. AUTO Mode Press the AUTO button. AUTO mode will be selected. A beep will sound and the text display will change to A***. The Auto LED will light The autopilot will lock on the current heading. The course-to-steer is shown on the display. Disengaging AUTO mode: Press the AUTO button, a beep will sound and the vessel will return to manual steering. Course Adjustment: Each press of the < or > buttons will give a course change of 1 in the applicable direction. The display will change to indicate the new course-to-steer. By pressing and holding the buttons TMQ AP46 Autopilot Page 9 of 34 Ver1.0 07/03/2007

10 pressed the course changes in 10 increments. This is used for larger turns. IMPORTANT!! Before entering AUTO mode, ensure that the rudder is in the centre position (ie: the vessel is steering approximately straight ahead). If you do not do this, the course steered will be different from that displayed. The AP46 autopilot will select the position of the rudder when AUTO is selected as the position of the rudder to allow the vessel to steer straight ahead. This can be an advantage in most vessels when a slight amount of helm from the physical centre position is required for the vessel to go straight. GPS Mode For use when interfaced to a GPS or plotting system generating NMEA 0183 data output in the correct sentence format. GPS mode allows the autopilot to be directed by the GPS, enabling automatic heading changes and eliminating the effects of wind and tide. The digital display indicates the course-to-steer, which will be the bearing between the origin and destination waypoints, plus a factor to correct for the current cross track error (XTE). Engaging GPS Mode: TMQ AP46 Autopilot Page 10 of 34 Ver1.0 07/03/2007

11 Press the MODE button and, while the MODE button is pressed, press the AUTO button. A beep will sound and the GPS and AUTO LED will be illuminated. The autopilot will lock on to course to steer as requested by the GPS. The course-to-steer is shown on the display. The vessel will begin turning from its Heading to that requested by the GPS unit, at a maximum rate of 10 degrees per second. If no GPS data is received by the AP46, the autopilot will lock onto the course of the vessel at the time that GPS Mode was engaged, and the NO GPS DATA alarm will function. Disengaging GPS Mode: Pressing the AUTO button will return the AP46 to Manual Mode. Setting up your GPS unit: Because there are a great variety of GPS units that will work with this autopilot, the following is a guide only. For more information, consult your GPS manual. TMQ AP46 Autopilot Page 11 of 34 Ver1.0 07/03/2007

12 The GPS unit must be set up to output NMEA 0183 data on a pair of wires, which are connected to the AP46 unit. The data generated must include at least one of the following: The APA sentence. The APB sentence. The BOD and XTE sentences. If only the XTE data sentence is available, the pilot can steer in a restricted manner only. (See later in this section.**) The GPS unit must be programmed and activated to navigate to a waypoint, or to follow a line joining two or more waypoints (called a route). This unit should then send information to the autopilot from which can be calculated the course-to-steer. Under the following conditions: Several waypoints are linked together into a single route, The GPS unit is set and capable of auto-sequence between them, An arrival zone of more than 0.05 NM (Nautical Miles) is set so that the GPS can detect when the vessel has reached a waypoint. Then the AP46 will be able to steer from each waypoint to the next without intervention. ** If only the XTE information is available from your GPS unit then your vessel must be on track, and heading in the correct direction, before engaging the GPS unit. The auto sequence feature is not available in this instance. Remember: Prior to engaging GPS mode, a route or destination must be programmed and selected in the GPS for the Autopilot to follow. TMQ AP46 Autopilot Page 12 of 34 Ver1.0 07/03/2007

13 No GPS Data Alarm: If the autopilot is not receiving valid information while in GPS Mode, the alarm will sound, and GPS and AUTO LED will flash. This could be caused by: Incorrect wiring of the GPS to the AP46 unit. Incorrect data output (wrong sentence) from the GPS unit. No route set up or selected in the GPS unit No location fix at the GPS unit. The vessel heading information generated by the GPS unit should closely correspond to the magnetic heading signal the AP46 is receiving from its magnetic compass. The greater the difference between these headings, the less accurate will be the GPS Mode steering. Ensure that the GPS unit has the correct magnetic correction factor. Ensure that the AP46 compass is correctly aligned and installed, and not subject to magnetic interference. Jog Mode In MANUAL mode The display screen shows H***, *** being the current vessel magnetic heading in degrees. The steering will operate in the direction selected by a < or > button press. TMQ AP46 Autopilot Page 13 of 34 Ver1.0 07/03/2007

14 NOTE. Do not hold either button down for too long a time (maximum 4 seconds) or the steering will be driven to the stops. Note: The limit controls are not operating in this mode. Driving the steering into the physical stops will damage your autopilot TMQ AP46 Autopilot Page 14 of 34 Ver1.0 07/03/2007

15 Rudder Sensitivity / Ratio These settings are used to determine how sensitive the autopilot system is and the amount of rudder the vessel requires for steering (actually, the amount of rudder angle applied for a given angle off-course). To adjust, press the MODE button. The display will show S ** and the present sensitivity setting will be displayed (between 1 and 10). The sensitivity setting may be altered by the < - > buttons. With a low response value the drive will operate with minimum pulsing to the required rudder position and the autopilot system may work continuously. A high response value the drive will position the rudder with maximum pulsing. NOTE: Too low a setting may cause the steering motor to work continuously (hunting). The response setting should be increased from 1 until the rudder position is achieved with 1 or 2 motor pulses. By pressing the MODE button a second time, the display will indicate r **. This setting is used for adjusting the autopilot s rudder ratio setting to allow for varying vessel size and speed. The display shall change to show r ** and display shall show the current rudder ratio (between 1 and 10). The rudder setting may be altered by the < - > buttons. TMQ AP46 Autopilot Page 15 of 34 Ver1.0 07/03/2007

16 A value of 1 signifies the minimum amount of applied rudder. When the rudder setting is too low, vessel track will be a slow S ie: understeer through too little rudder applied. A value of 10 signifies the maximum amount of applied rudder. When the rudder setting is too high, vessel track will be a rapid S ie: oversteer through too much rudder applied. Backlighting Pressing the MODE button four times will display the message LitE Pressing either the < or > buttons will turn the backlighting on and off. The backlighting will always be off when the unit is powered up. Rudder Angle Indicator Pressing the MODE button three times will display the rudder position in numeric value Port or Starboard When the rudder is at centre it will display 00 As port rudder angle is applied, the number will be Pt**. As starboard rudder angle is applied, the numbers will be St**. Pressing MODE or AUTO will cancel the rudder display. TMQ AP46 Autopilot Page 16 of 34 Ver1.0 07/03/2007

17 Initial Settings Selecting the Initial settings of the Autopilot: A number of system settings may need to be carried out prior to using the AP46 Autopilot. Two initial settings can be checked from the display Head. Motor Direction Rudder Limits Motor Direction In manual mode with the display showing a compass heading, pressing port or starboard buttons (< >) should drive the rudder in the direction indicated on the button. Reverse motor wires if incorrect. Rudder Limits The rudder limits prevent the steering motor driving the rudder beyond its physical (mechanical) stops. The limits are factory set and should not need altering. However, the limit setting can be set from the display of the AP46 if deemed necessary. Set the rudder to the desired Port position Select SET PORT LIMIT. By pressing the MODE button five times until PL** is displayed Press the < > buttons simultaneously to set the Port Limit. Set the rudder to the desired Starboard position Select SET STARBOARD LIMIT. By pressing the MODE button six times SL** is displayed TMQ AP46 Autopilot Page 17 of 34 Ver1.0 07/03/2007

18 Press the < > buttons simultaneously to set the Starboard Limit. The number on the display will be between 0 and 31 to indicate the rudder position. SL31 being fully to Starboard and PL31 being fully to port. If --- (out of range) is displayed it indicates the rudder is not in the correct position to set the rudder limit, eg: Rudder is to port when setting the Starboard limit. If at any time during testing the motor runs under load and the rudder does not move, checks should be carried out to confirm the limit switches are operating prior to the rudder running into the stops. Reset Rudder Limits It is possible to reset the rudder limits to the factory settings if unsure of the settings. Press the MODE Button 7 Times rlr will Display (Reset Limit Rudder). Press < > both simultaneously to reset rudder limit. Compass Calibration The compass is set to carry out an automatic compass calibration if the vessel is turned through 360 within 4 minutes. If the AP46 compass heading displays a constant offset when compared to a correctly calibrated ships compass (eg: the autopilot compass reads 3 high on all headings), simply rotate the AP46 compass sensor to align the displayed headings with the ships compass. TMQ AP46 Autopilot Page 18 of 34 Ver1.0 07/03/2007

19 If the compass is reading H000, the possibility is the compass is not functioning or disconnected. Alarms A number of conditions will cause alarms to sound and an alarm message to flash on the display Off Course Alarm The AP46 allows for monitoring of the autopilot course holding ability by having the angle off-course measured and alarm sounding if greater than 45 from the desired course. If the difference is greater than 45 between the heading and the course to steer, the alarm will sound and the ALARM LED will flash GPS Alarm NO GPS DATA Alarm The alarm sounds if the autopilot is not receiving valid information from the GPS. The ALARM LED will flash. TMQ AP46 Autopilot Page 19 of 34 Ver1.0 07/03/2007

20 Installation of AP46 Head Unit Position: The AP46 Head unit should be mounted in a position accessible to the steering position and protected from direct rain or salt water. A hole of 70mm (2.5inches) is required for the rear of the unit. Wiring: Access for wiring must be provided from the AP46 Head to compass assembly. Wiring should be kept as far as possible from radio aerials and aerial cables to prevent interference to the radio and transmitted signals from the radio influencing the autopilot. Cable should also be run separately (if practical) from other current-carrying cables. There is no restriction on cable length. Magnetic Effect: As no steel is used in theap46 Head, there is negligible effect on a steering compass. Some radio interference may be caused by the internal electronics. Installation of Compass The AP46 Autopilot is supplied with a Compass Sensor The Compass Sensor should be treated with care. TMQ AP46 Autopilot Page 20 of 34 Ver1.0 07/03/2007

21 Position: The compass position is the most important item in the installation of the autopilot. Good course holding is dependent on the compass being free from magnetic interference. As the compass has no moving card, it is not necessary for the compass to be mounted low in the vessel. This can be a place of high magnetic interference and should be avoided. However, a position where excessive roll is experienced, such as the top of a mast, should not be used. The compass is weatherproof, not waterproof. A position not open to the elements should be selected. It can be mounted on top of a flat surface, on a bulkhead or from the deck head. NOTE: Check other side of bulkhead for materials, which may cause magnetic interference. Wiring: The cable leading from the compass / processor must be connected to the COMPASS socket on the AP46. Do not run the compass cable with other cables on the vessel. The compass is supplied with a standard 5 metre length cable. Magnetic Effect: Interference from any iron or steel can cause degraded operation of the compass unit. To prevent this occurring a minimum distance of 1 metre (3 feet) should be kept from any steel or other ferromagnetic materials. This includes speakers and radios with internal speakers. TMQ AP46 Autopilot Page 21 of 34 Ver1.0 07/03/2007

22 Mounting: Fasten the compass with the non-magnetic screws supplied. The compass must be mounted as near as possible to a vertical position. Calibration: The compass will need to be rotated for the correct heading to be displayed. During sea trials further adjustment may be required to reduce any heading error displayed. The compass is calibrated in the factory and set for auto calibrate. TMQ AP46 Autopilot Page 22 of 34 Ver1.0 07/03/2007

23 TMQ AP46 Autopilot Page 23 of 34 Ver1.0 07/03/2007

24 Wiring: Access for wiring must be provided. Cabling will have to be run to the power switchboard, rudder feedback unit, display head and drive unit. Wiring should be kept as far as possible from radio aerials and aerial cables to prevent interference to the radio and to prevent transmitted signals from the radio influencing the AP46 unit The AP46 must have a direct connection to power supply via a 15 amp circuit breaker or a 15 amp fused circuit and an isolating switch. AP46 Head Wiring Diagram

25 Installation of Rudder Feedback Position: Install rudder feedback as shown in the diagram labelled Rudder Feedback Unit Installation (next page). The unit should be adjacent to the tiller and must copy the angular movement of the tiller. The markings on the rudder feedback unit indicate the required movement of the tiller for course correction. It should be installed with the shaft uppermost, mounted in such a way that the four points (tiller post, feedback shaft and the two adjustable linkage points) form the four corners of a parallelogram. The rudder feedback unit is water resistant. However, if it is to be mounted in a wet position, some protection should be provided to ensure the unit does not become excessively exposed to water. If necessary, the rudder feedback unit may be mounted upside down, in which case the blue and red wires in the cable must be reversed. (Note: yellow wire in cable is not used in the RFU). When installation of the feedback unit is complete and the linkage is fitted, have the steering of the vessel moved from lock to lock and ensure: a) The direction indicated on the top of the RFU is correct. b) No undue mechanical strain is placed on the rudder feedback or linkage. TMQ AP46 Autopilot Page 25 of 34 Ver1.0 07/03/2007

26 Rudder Feedback Installation Diagram Rudder Feedback Installation Notes When the rudder is central and the rudder feedback is central all angles should be 90. Use the snap swivel and ball joint on the rudder feedback arm Use the rudder feedback adjustment block on the tiller arm Hydraulic ram may be mounted on the other side of the tiller arm Ensure that when rudder turns to Port, Rudder Feedback turns to Port as indicated on the rudder feedback unit. Rudder feedback unit may be mounted upside down. This would require an electrical change. (Polarity of rudder feedback requires reversing) TMQ AP46 Autopilot Page 26 of 34 Ver1.0 07/03/2007

27 RFU Wiring: The cable from the RFU must be connected to the RUDDER socket on the AP46 unit. The RFU is supplied with a standard 14-metre cable but can be extended if required during installation. See Rudder feedback wiring diagram, page 32. NOTE 1: THE RUDDER FEEDBACK UNIT IS FACTORY ALIGNED. THE ARM SHOULD NOT BE REMOVED OR LOOSENED AS THE FEEDBACK ARM HOLDS AN O-RING AGAINST THE FEEDBACK BODY TO FORM PART OF THE WATER RESISTANT SEAL. Rudder Feedback / GPS Wiring Diagrams Pin connections from rear of plug, solder connection side. Pin 1 has adjacent dot. Figure 1 Rudder Feedback / GPS Connection Diagram Pin1 5V Rudder Feedback Supply Pin2 Rudder Feedback Wiper Return Pin3 0v Rudder Feedback Supply Pin4 TX Data (heading information) Pin5 + GPS Input (Positive) Pin6 - GPS Input (Negative) Note: Pin locations are relative to pin 1 which always has a dot adjacent. TMQ AP46 Autopilot Page 27 of 34 Ver1.0 07/03/2007

28 GPS Connection For GPS navigation, connect the GPS unit via the two wires coming from the back of the rudder feedback plug on the AP46 display unit. The connections on the plug are: Pin 5 DATA IN+ (white) Pin 6 DATA COM (green) For information on connecting different brands of GPS units, refer to the relevant GPS manual. TMQ AP46 Autopilot Page 28 of 34 Ver1.0 07/03/2007

29 Reversing Pump Connection The reversing pump is connected to the yellow wires from the display unit. Cable length can be shortened or extra cable added. Check cable used is off sufficient size to carry the motor current (Can be up to 15 amps peak) Check motor direction with jog mode, reverse if required. Where a bypass valve or clutch is required the green wire supplies switched negative power whenever POWER or AUTO is selected. TMQ AP46 Autopilot Page 29 of 34 Ver1.0 07/03/2007

30 Testing Procedure Initial Inspection and Testing 1. Confirm power to be connected is the required DC voltage. 2. Power Supply 12V DC is available. 3. Ensure polarity of the voltage supply is correct. 4. All electrical connections are correct. 5. Loose cables are clipped or tied up. Dockside Tests 1. Turn steering wheel fully clockwise and visually check that moving (mechanical) parts do not foul; visually check that RFU has moved in correct direction as indicated on the RFU label on top. 2. Repeat step 1 for anti-clockwise. 3. Return Steering to centre and Ensure RFU is at centre. 4. Switch on AP46 Autopilot system and select Rudder Angle Indicator by pressing the Mode button three times. 5. Press arrow button to operate steering in that direction 6. Check that rudder moves in correct direction 7. Check Rudder direction follows change request 8. Check Course change provides sufficient Rudder movement 9. Adjust Rudder Limits with display ONLY if required 10. Check magnetic heading display on AP46 TMQ AP46 Autopilot Page 30 of 34 Ver1.0 07/03/2007

31 Trouble Shooting Unit does not move rudder when AUTO is selected Confirm AP46 LCD is displaying information. Check voltage is present at the AP46 motor connections (Yellow) when AUTO is selected and a course change applied. Confirm that the supply voltage is 12 volts DC (Red and Black). If using solenoid valves with an external power supply, check that power is present. Check all motor and / or solenoid valve wiring. Check the hydraulic system: 1. Ensure there is sufficient hydraulic fluid. 2. Purge the system of possible air locks / contamination. 3. Ensure that any flow restricting valves are not completely closed. 4. Check all connections for leaks. Rudder drive hard over After installation of the autopilot System if the rudder drives hard over to their mechanical stops in the wrong direction, the motor connections may need reversing or the solenoid valves connectors may need to be swapped. Rudder drives hard over to the mechanical stops in the correct direction; 1. Check rudder feedback unit is connected to the rudder arm 2. Check rudder feedback cable for damage. 3. Ensure the rudder feedback plug is firmly connected to the AP46 unit and indicates on display when RFU mode selected. TMQ AP46 Autopilot Page 31 of 34 Ver1.0 07/03/2007

32 TMQ AP46 Autopilot Page 32 of 34 Ver1.0 07/03/2007

33 Optional Extras TMQ Electronics can supply a range of pumps for the AP46 Autopilot. Further hydraulic pump information and other product information can be obtained from the TMQ website at Hydraulic Drives and Pump Units Reversible pumps Hydraulic pumps available in 12 volts DC with 1 or 2 litre capacity to suit recreational, work boat or fishing applications. Continuous pumps Constant running pumps available in 2 or 3 litre for 12 volt DC systems. Accurate flow adjustment to set lock-tolock time. TMQ AP46 Autopilot Page 33 of 34 Ver1.0 07/03/2007

34 TMQ AP46 Autopilot Page 34 of 34 Ver1.0 07/03/2007

35 Technician set up procedure A procedure has been included in the software to adjust the motor control response. This can be entered when in standby (MANUAL) by pressing the mode button until P-10 is displayed. Then pressing the two arrow ( < > ) buttons together twice. The motor routine will then be displayed in 4 settings. 1 Pulse length 2 Reverse delay 3 Dead band 4 Pulsing frequency To adjust, select the number to be adjusted, press both arrows together to select the mode. Indicated by 1 05 Adjust up or down with the arrows. Press both arrows together to deselect the mode. Indicated by 1-05 Press MODE or AUTO to return to normal pilot operation. TMQ AP46 Autopilot Page 35 of 34 Ver1.0 07/03/2007

AP55 Display OPERATION AND INSTALLATION MANUAL.

AP55 Display OPERATION AND INSTALLATION MANUAL www.tmq.com.au Index INDEX... 2 INTRODUCTION... 3 System configuration... 3 System Block Diagram... 4 Definition of Terms... 6 Overview of Operation... 8

AP55 Display OPERATION AND INSTALLATION MANUAL www.tmq.com.au Index INDEX... 2 INTRODUCTION... 3 System configuration... 3 System Block Diagram... 4 Definition of Terms... 6 Overview of Operation... 8

˵à Êé OPERATOR'S MANUAL. Autopilot

KAP-833 KAP833 ˵à Êé OPERATOR'S MANUAL Autopilot Warning! Automatic pilots are designed to be a navigational aid. As an automatic steering aid, an autopilot can alleviate the boredom of hand steering.

KAP-833 KAP833 ˵à Êé OPERATOR'S MANUAL Autopilot Warning! Automatic pilots are designed to be a navigational aid. As an automatic steering aid, an autopilot can alleviate the boredom of hand steering.

SP-110 Autopilot OPERATION

SP-110 Autopilot OPERATION www.si-tex.com Warning! WHEN USING THE AUTOPILOT AN ADEQUATE WATCH SHOULD BE MAINTAINED AT ALL TIMES. THE AUTOPILOT MUST BE PLACED IN MANUAL MODE WHEN EVER THE VESSEL IS STATIONARY

SP-110 Autopilot OPERATION www.si-tex.com Warning! WHEN USING THE AUTOPILOT AN ADEQUATE WATCH SHOULD BE MAINTAINED AT ALL TIMES. THE AUTOPILOT MUST BE PLACED IN MANUAL MODE WHEN EVER THE VESSEL IS STATIONARY

frequently asked questions

Hydra Pilot Fault Codes What do the fault codes for the Hydra Pilot mean? Fault Cause FAULT 100 FAULT 101 FAULT 102 FAULT 103 FAULT 104 FAULT 105 FAULT 106 FAULT 108 FAULT 109 FAULT 110 FAULT 111 FAULT

Hydra Pilot Fault Codes What do the fault codes for the Hydra Pilot mean? Fault Cause FAULT 100 FAULT 101 FAULT 102 FAULT 103 FAULT 104 FAULT 105 FAULT 106 FAULT 108 FAULT 109 FAULT 110 FAULT 111 FAULT

INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 SELECTING THE DISPLAY MODE 5 ABBREVIATIONS AND DEFINITIONS 17

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

Autopilot setup. VRF (Virtual Rudder Feedback) calibration. Software setup NSS evo2 Installation Manual

Autopilot setup Verifying the autopilot connection When an AC12N, AC42N, or SG05 is connected to the NSS evo2 system, the NSS evo2 will automatically detect the autopilot and an Autopilot menu icon will

Autopilot setup Verifying the autopilot connection When an AC12N, AC42N, or SG05 is connected to the NSS evo2 system, the NSS evo2 will automatically detect the autopilot and an Autopilot menu icon will

Explorer AP380 Autopilot Installation and Operation Manual

Explorer AP380 Autopilot Installation and Operation Manual www.northstarnav.com IMPORTANT SAFETY INFORMATION Please read carefully before installation and use. DANGER! WARNING! CAUTION CAUTION This is

Explorer AP380 Autopilot Installation and Operation Manual www.northstarnav.com IMPORTANT SAFETY INFORMATION Please read carefully before installation and use. DANGER! WARNING! CAUTION CAUTION This is

User s Guide. Leisure Pilots 715, 730 & 740. for. Issue 06 for use with version V3.00 software (or later) in the Pilot Computer

User s Guide for Leisure Pilots 715, 730 & 740 Issue 06 for use with version V3.00 software (or later) in the Pilot Computer Welcome... All of us at would like to welcome you to the reliable world of our

User s Guide for Leisure Pilots 715, 730 & 740 Issue 06 for use with version V3.00 software (or later) in the Pilot Computer Welcome... All of us at would like to welcome you to the reliable world of our

REACTOR 40 MECHANICAL Configuration Guide

REACTOR 40 MECHANICAL Configuration Guide Important Safety Information WARNING See the Important Safety and Product Information guide in the product box for product warnings and other important information.

REACTOR 40 MECHANICAL Configuration Guide Important Safety Information WARNING See the Important Safety and Product Information guide in the product box for product warnings and other important information.

PART 5 - OPTIONS CONTENTS 5.1 SYSTEM EXPANSION 5-3

PART 5 - OPTIONS CONTENTS Para Page 5.1 SYSTEM EXPANSION 5-3 5.2 SENSORS 5-3 5.2.1 Trim Angle Sensor 5-3 5.2.2 Mast Rotation Sensor 5-3 5.2.3 Heel Angle Sensor 5-3 5.2.4 Barometric Pressure Sensor 5-3

PART 5 - OPTIONS CONTENTS Para Page 5.1 SYSTEM EXPANSION 5-3 5.2 SENSORS 5-3 5.2.1 Trim Angle Sensor 5-3 5.2.2 Mast Rotation Sensor 5-3 5.2.3 Heel Angle Sensor 5-3 5.2.4 Barometric Pressure Sensor 5-3

GHC 20. Owner s Manual

GHC 20 Owner s Manual 2013 Garmin Ltd. or its subsidiaries All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin

GHC 20 Owner s Manual 2013 Garmin Ltd. or its subsidiaries All rights reserved. Under the copyright laws, this manual may not be copied, in whole or in part, without the written consent of Garmin. Garmin

GHC 20 Owner s Manual

GHC 20 Owner s Manual Introduction See the Important Safety and Product Information guide in the product box for product warnings and other important information. You are responsible for the safe and prudent

GHC 20 Owner s Manual Introduction See the Important Safety and Product Information guide in the product box for product warnings and other important information. You are responsible for the safe and prudent

WIND CLIPPER KTS ILLUM SCALE INC DEC CLIPPER WIND SYSTEM

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

USER MANUAL. Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK. Tel: (+44) Fax: (+44)

USER MANUAL Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK Tel: (+44) 01590 689699 Fax: (+44) 01590 610072 www.bandgservice.co.uk Brookes and Gatehouse Ltd. 2000 The copyright of this Manual is

USER MANUAL Premier Way, Abbey Park Romsey Hampshire, SO51 9DH, UK Tel: (+44) 01590 689699 Fax: (+44) 01590 610072 www.bandgservice.co.uk Brookes and Gatehouse Ltd. 2000 The copyright of this Manual is

CONTENTS STEER TO VANE MODE...

CONTENTS GENERAL INTRODUCTION TO B&G NETWORK... 2 INTRODUCTION TO NETWORK PILOT... 3 SWITCHING THE NETWORK PILOT ON... 3 NETWORK PILOT DISPLAY UNIT... 4 NETWORK PILOT HAND-HELD CONTROLLER... 5 JOYSTICK

CONTENTS GENERAL INTRODUCTION TO B&G NETWORK... 2 INTRODUCTION TO NETWORK PILOT... 3 SWITCHING THE NETWORK PILOT ON... 3 NETWORK PILOT DISPLAY UNIT... 4 NETWORK PILOT HAND-HELD CONTROLLER... 5 JOYSTICK

Steer to Wind angle, Wind Mode, when connected to the h1000 Wind Interface

h1000 pilot introduction overview Congratulations on your purchase of the h1000 Pilot from B&G. The h1000 Pilot is the latest in autopilots from B&G and represents B&G s commitment to providing our customers

h1000 pilot introduction overview Congratulations on your purchase of the h1000 Pilot from B&G. The h1000 Pilot is the latest in autopilots from B&G and represents B&G s commitment to providing our customers

RAI-M series RUDDER ANGLE INDICATOR SYSTEM

RUDDER ANGLE INDICATOR SYSTEM RAI-M series SEAFIRST ENGINEERING CO 45-16, Ga Um Dong, Chang Won, Kyong Nam Korea Tel : 82 55 267 1645 Fax ; 82 55 266 1646 http://www.seafirst.co.kr GENERAL Seafirst Rudder

RUDDER ANGLE INDICATOR SYSTEM RAI-M series SEAFIRST ENGINEERING CO 45-16, Ga Um Dong, Chang Won, Kyong Nam Korea Tel : 82 55 267 1645 Fax ; 82 55 266 1646 http://www.seafirst.co.kr GENERAL Seafirst Rudder

Pilot 3380 A U T O P I L O T. Operation Manual NAVMAN

Pilot 3380 A U T O P I L O T Operation Manual w w w. n a v m a n. c o m NAVMAN FCC Statement Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

Pilot 3380 A U T O P I L O T Operation Manual w w w. n a v m a n. c o m NAVMAN FCC Statement Note: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

TECNAUTIC_GmbH. Display Functions with the PB100/200 connected: -- GND Speed -- GND Course -- Heading (Gyro option is recommended) 2 m

PB100/200 Sonic Wind Wind, GPS, Compass Display Config: SE=12 di=00 df=20,91,30,34,(61) 35,36,81 Gr=01 n0=00 n1=07 n2=07**) n3=00 Display Functions with the PB100/200 connected: -- Apparent Wind -- True

PB100/200 Sonic Wind Wind, GPS, Compass Display Config: SE=12 di=00 df=20,91,30,34,(61) 35,36,81 Gr=01 n0=00 n1=07 n2=07**) n3=00 Display Functions with the PB100/200 connected: -- Apparent Wind -- True

Model 130M Pneumatic Controller

Instruction MI 017-450 May 1978 Model 130M Pneumatic Controller Installation and Operation Manual Control Unit Controller Model 130M Controller is a pneumatic, shelf-mounted instrument with a separate

Instruction MI 017-450 May 1978 Model 130M Pneumatic Controller Installation and Operation Manual Control Unit Controller Model 130M Controller is a pneumatic, shelf-mounted instrument with a separate

Simrad yachting catalog 2007

26 AUTOSTEERING Electronic intelligence combined with powerful and reliable designs make sure you enjoy boating even more. 27 Tillerpilots Enjoy silence when sailing SIMRAD TP SERIES REMOTE COMMANDER High

26 AUTOSTEERING Electronic intelligence combined with powerful and reliable designs make sure you enjoy boating even more. 27 Tillerpilots Enjoy silence when sailing SIMRAD TP SERIES REMOTE COMMANDER High

GHC Remote Control Instructions manual

GHC Remote Control Instructions manual Instructions What s In The Box Before installing your remote, confirm that your package includes these items. GHC Remote Control Two GHC Remote Control cradles Four

GHC Remote Control Instructions manual Instructions What s In The Box Before installing your remote, confirm that your package includes these items. GHC Remote Control Two GHC Remote Control cradles Four

TOP BLEED Position for SeaTalk 2 colour logo ST 30. COMPASS Operation and Installation

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. TOP BLEED Position for SeaTalk 2 colour

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. TOP BLEED Position for SeaTalk 2 colour

Installation, Compensation and Maintenance Instructions for. RITCHIE Compasses. Made In U.S.A

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

A4 Operation Manual. Fig.1-1 Controller Socket Diagram

A4 Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

A4 Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

A4s Operation Manual

A4s Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

A4s Operation Manual Safety Instruction Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller properly and

Roller AC Servo System

Safely Instruction Roller AC Servo System HMI-15 User Manual Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller

Safely Instruction Roller AC Servo System HMI-15 User Manual Please read this manual carefully, also with related manual for the machinery before use the controller. For installing and operating the controller

S100 Controller. User guide. English Date: Document number: EN 2006 Raymarine UK Limited

S100 Controller User guide English Date: 06-2006 Document number: 81242-4-EN 2006 Raymarine UK Limited 1 - Getting Started Changing the Controller batteries... 5 The S100 Autopilot Controller... 6 How

S100 Controller User guide English Date: 06-2006 Document number: 81242-4-EN 2006 Raymarine UK Limited 1 - Getting Started Changing the Controller batteries... 5 The S100 Autopilot Controller... 6 How

1420 Autopilot System. Installation & Operation Manual

1420 Autopilot System Installation & Operation Manual WELCOME Congratulations on your purchase of a ComNav Marine 1420 Autopilot System! At ComNav, we are dedicated to reliability & quality in all our

1420 Autopilot System Installation & Operation Manual WELCOME Congratulations on your purchase of a ComNav Marine 1420 Autopilot System! At ComNav, we are dedicated to reliability & quality in all our

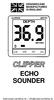

INSTALLING THE ECHO SOUNDER TRANSDUCER CHANGING THE OPERATING CONFIGURATION

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

Welcome. Warranty Notice. Operator s Warning. General Notice. ComNav Marine Ltd. ComNav Admiral P3 Installation & Operation

Admiral P3 Wheelmark Autopilot System Installation & Operation Manual 0801/06 USCG Approval Number: 165.110/EC0801/MED3280206 PN 29010075 COMPLIES WITH CE REGULATIONS Welcome Welcome Congratulations on

Admiral P3 Wheelmark Autopilot System Installation & Operation Manual 0801/06 USCG Approval Number: 165.110/EC0801/MED3280206 PN 29010075 COMPLIES WITH CE REGULATIONS Welcome Welcome Congratulations on

AHE58/59 AC Servo System

AHE58/59 AC Servo System HMI-12 User Manual Safely INstruction Please read this manual carefully, also with related manual for the machine head before use. For perfect operation and safety, installing

AHE58/59 AC Servo System HMI-12 User Manual Safely INstruction Please read this manual carefully, also with related manual for the machine head before use. For perfect operation and safety, installing

INSTALLATION MANUAL 2001 AUTOPILOT

INSTALLATION MANUAL 2001 AUTOPILOT WARRANTY NOTICE Prior to the installation and/or operation of the Equipment, ensure that you read, understand and accept the conditions of the warranties as detailed

INSTALLATION MANUAL 2001 AUTOPILOT WARRANTY NOTICE Prior to the installation and/or operation of the Equipment, ensure that you read, understand and accept the conditions of the warranties as detailed

ECONORESS ELECTRONIC EPS & EPT - ENHANCED PRESSURISATION SET INSTALLATION OPERATION & MAINTENANCE DOCUMENTATION

ECONORESS ELECTRONIC EPS & EPT - ENHANCED PRESSURISATION SET INSTALLATION OPERATION & MAINTENANCE DOCUMENTATION OCT2010 STOKVIS ENERGY SYSTEMS 96R WALTON ROAD EAST MOLESEY SURREY KT8 0DL TEL: 020 87833050

ECONORESS ELECTRONIC EPS & EPT - ENHANCED PRESSURISATION SET INSTALLATION OPERATION & MAINTENANCE DOCUMENTATION OCT2010 STOKVIS ENERGY SYSTEMS 96R WALTON ROAD EAST MOLESEY SURREY KT8 0DL TEL: 020 87833050

SmartPilot X-Series. Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems

SmartPilot X-Series Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems Document reference: 81307-1 Date: December 2007 SeaTalk is a registered trademark of Raymarine Ltd.

SmartPilot X-Series Commissioning & Setup Guide (SeaTalk) for SPX-10, SPX-30, SPX-SOL & SPX-CAN Systems Document reference: 81307-1 Date: December 2007 SeaTalk is a registered trademark of Raymarine Ltd.

UBEC 1AT. AUTO TANK Fill System Installation, Operation, & Setup Instructions

Document Number: XE-ATA5PM-R1A UBEC 1AT AUTO TANK Fill System 08899155 Installation, Operation, & Setup Instructions Rev170906-EB-FRC PHYSICAL: 1302 WEST BEARDSLEY AVE ELKHART, IN 46514 WWW.ELKHARTBRASS.COM

Document Number: XE-ATA5PM-R1A UBEC 1AT AUTO TANK Fill System 08899155 Installation, Operation, & Setup Instructions Rev170906-EB-FRC PHYSICAL: 1302 WEST BEARDSLEY AVE ELKHART, IN 46514 WWW.ELKHARTBRASS.COM

USER GUIDE FOR DATALINE-X SDX. Stowe Marine Ltd. Tel +44(0)

USER GUIDE FOR DATALINE-X SDX Stowe Marine Ltd. www.stowemarine.com Tel +44(0)1590 610071 Dataline-X SDX Manual, Part Number 05707SM, Issue 2, Dec 1995. Warning The equipment to which this manual applies

USER GUIDE FOR DATALINE-X SDX Stowe Marine Ltd. www.stowemarine.com Tel +44(0)1590 610071 Dataline-X SDX Manual, Part Number 05707SM, Issue 2, Dec 1995. Warning The equipment to which this manual applies

Misaligned Folds Paper Feed Problems Double Feeds Won t Feed FLYER Won t Run iii

Operator s Manual Table of Contents Operator Safety... 1 Introduction... 2 Unpacking and Setup... 3 Unpacking... 3 Setup... 4 FLYER Overview... 5 FLYER Diagram... 5 Capabilities... 5 Control Panel... 6

Operator s Manual Table of Contents Operator Safety... 1 Introduction... 2 Unpacking and Setup... 3 Unpacking... 3 Setup... 4 FLYER Overview... 5 FLYER Diagram... 5 Capabilities... 5 Control Panel... 6

ACV-10 Automatic Control Valve

ACV-10 Automatic Control Valve Installation, Operation & Maintenance General: The Archer Instruments ACV-10 is a precision automatic feed rate control valve for use in vacuum systems feeding Chlorine,

ACV-10 Automatic Control Valve Installation, Operation & Maintenance General: The Archer Instruments ACV-10 is a precision automatic feed rate control valve for use in vacuum systems feeding Chlorine,

AUTOMATIC GAS MANIFOLDS

AUTOMATIC GAS MANIFOLDS Phoenix Pipeline Products Limited. Unit 8, McKenzie Industrial Park, Tel No.: 44 (0) 161 428 7200 Bird Hall Lane, Fax No.: 44 (0) 161 428 7010 Stockport, Email: info@p3-phoenix.com

AUTOMATIC GAS MANIFOLDS Phoenix Pipeline Products Limited. Unit 8, McKenzie Industrial Park, Tel No.: 44 (0) 161 428 7200 Bird Hall Lane, Fax No.: 44 (0) 161 428 7010 Stockport, Email: info@p3-phoenix.com

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units Models: EPS Single Pump EPT Twin Pump EPS-HP EPT-HP Single Pump High Pressure Twin Pump High Pressure

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units Models: EPS Single Pump EPT Twin Pump EPS-HP EPT-HP Single Pump High Pressure Twin Pump High Pressure

SI-TEX SP36 Autopilot

SI-TEX SP36 Autopilot Installation & Operation Manual PN 29010086 V1.0 Warranty Notice Prior to the installation and/or operation of the equipment, please take a moment to read and accept the conditions

SI-TEX SP36 Autopilot Installation & Operation Manual PN 29010086 V1.0 Warranty Notice Prior to the installation and/or operation of the equipment, please take a moment to read and accept the conditions

User Manual GRI- 1500Li

User Manual GRI- 1500Li Your Cart Tek caddy cart was thoroughly quality control checked and road tested before being shipped to your address. We do everything possible to assure that your caddy is in perfect

User Manual GRI- 1500Li Your Cart Tek caddy cart was thoroughly quality control checked and road tested before being shipped to your address. We do everything possible to assure that your caddy is in perfect

MP15 Jockey Pump Controller

Setup and Operating Instructions MP15 Jockey Pump Controller This manual provides general information, installation, operation, maintenance, and system setup information for Metron Model MP15 Jockey Pump

Setup and Operating Instructions MP15 Jockey Pump Controller This manual provides general information, installation, operation, maintenance, and system setup information for Metron Model MP15 Jockey Pump

TS-202 FFU Lever Remote Part Number & Operation & Installation Instructions Version 2.1

R TS-202 FFU Lever Remote Part Number 20310020 & 20310029 Operation & Installation Instructions Version 2.1 ComNav Marine Ltd. 15 13511 Crestwood Place. Richmond, B.C. Canada. V6V-2G1 Document PN 29010046

R TS-202 FFU Lever Remote Part Number 20310020 & 20310029 Operation & Installation Instructions Version 2.1 ComNav Marine Ltd. 15 13511 Crestwood Place. Richmond, B.C. Canada. V6V-2G1 Document PN 29010046

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission

- Course Processor R

http://nex / /Autopilot/dig_auto.tif Autopilot - Course Processor R-1600 - Installation and Operation Manual AUTOPILOT 8-1 AUTOPILOT This manual is written for NX2 Autopilot version 1.00 Edition: May 2012

http://nex / /Autopilot/dig_auto.tif Autopilot - Course Processor R-1600 - Installation and Operation Manual AUTOPILOT 8-1 AUTOPILOT This manual is written for NX2 Autopilot version 1.00 Edition: May 2012

S1000+ / S2000+ Tiller Pilots. Owner s manual

S1000+ / S2000+ Tiller Pilots Owner s manual Chapter 1: Introduction Chapter 1: Introduction 1.1 Overview D5557-2 Your Raymarine tiller pilot is a totally self-contained autopilot designed for tiller steered

S1000+ / S2000+ Tiller Pilots Owner s manual Chapter 1: Introduction Chapter 1: Introduction 1.1 Overview D5557-2 Your Raymarine tiller pilot is a totally self-contained autopilot designed for tiller steered

S1000+ / S2000+ Tiller Pilots

S1000+ / S2000+ Tiller Pilots Owner s handbook English Date: 12-2013 Document number: 81130-7-EN 2013 Raymarine UK Limited 1 Contents Contents... 1 Chapter 1: Introduction...3 1.1 Overview... 3 1.2 Specifications...

S1000+ / S2000+ Tiller Pilots Owner s handbook English Date: 12-2013 Document number: 81130-7-EN 2013 Raymarine UK Limited 1 Contents Contents... 1 Chapter 1: Introduction...3 1.1 Overview... 3 1.2 Specifications...

TANK MANAGER FOR TWO TANKS OPERATING MANUAL. 10/31/11 C-More T6C L color touch panel

TANK MANAGER FOR TWO TANKS OPERATING MANUAL 10/31/11 C-More T6C L color touch panel 1 TABLE OF CONTENTS GENERAL...3 INSTALLATION...4 STONE TEST PROCEDURE...7 OPERATIONAL SUMMARY...7 AUTO CARBONATION...10

TANK MANAGER FOR TWO TANKS OPERATING MANUAL 10/31/11 C-More T6C L color touch panel 1 TABLE OF CONTENTS GENERAL...3 INSTALLATION...4 STONE TEST PROCEDURE...7 OPERATIONAL SUMMARY...7 AUTO CARBONATION...10

ST600R Autopilot Control Unit Owner s Handbook. Document number: Date: May 2001

ST600R Autopilot Control Unit Owner s Handbook Document number: 81134-3 Date: May 2001 -10-1 +10 +1 Preface i stdby auto track Raymarine, as part of its commitment to continuous improvement and updating,

ST600R Autopilot Control Unit Owner s Handbook Document number: 81134-3 Date: May 2001 -10-1 +10 +1 Preface i stdby auto track Raymarine, as part of its commitment to continuous improvement and updating,

h2000 Autopilot User Manual

h2000 Autopilot User Manual! WANING The use of solvent based or chemical cleaners on the Pilot Displays will result in damage and invalidate your warranty. Premier Way Abbey Park, omsey Hampshire, SO51

h2000 Autopilot User Manual! WANING The use of solvent based or chemical cleaners on the Pilot Displays will result in damage and invalidate your warranty. Premier Way Abbey Park, omsey Hampshire, SO51

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH METRES ECHO SOUNDER.

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

AutoChanger Installation & User Guide Issue 2

1 INDEX Page 1. Introduction... 3 2. AutoChanger Components Guide 4 3. Installation. 5-11 a) Installation Guidelines.. 5 b) Installation Retrofit... 6-11 c) Installation New... 11 4. AutoChanger User Guide

1 INDEX Page 1. Introduction... 3 2. AutoChanger Components Guide 4 3. Installation. 5-11 a) Installation Guidelines.. 5 b) Installation Retrofit... 6-11 c) Installation New... 11 4. AutoChanger User Guide

PROPORTIONING VALVE. Model 150 INSTRUCTION MANUAL. March 2017 IMS Company Stafford Road

PROPORTIONING VALVE Model 150 INSTRUCTION MANUAL March 2017 IMS Company 10373 Stafford Road Telephone: (440) 543-1615 Fax: (440) 543-1069 Email: sales@imscompany.com 1 Introduction IMS Company reserves

PROPORTIONING VALVE Model 150 INSTRUCTION MANUAL March 2017 IMS Company 10373 Stafford Road Telephone: (440) 543-1615 Fax: (440) 543-1069 Email: sales@imscompany.com 1 Introduction IMS Company reserves

CCT-7320/ROC-2313 Reverse Osmosis Controller

CCT-7320/ROC-2313 Reverse Osmosis Controller 1 General The instrument is a combined control instrument of a reverse osmosis controller and an on-line conductivity instrument. It can perform the operation

CCT-7320/ROC-2313 Reverse Osmosis Controller 1 General The instrument is a combined control instrument of a reverse osmosis controller and an on-line conductivity instrument. It can perform the operation

GATE 2 Part No

PAGE 1 GATE 2 Part No. 23001125 SWING GATE CTROLLER INSTALLATI GUIDE Page 2 GATE 2 Code No. 23001125 Electronic Control Board for use with SEA Hydraulic or Electro-mechanical swing gate operators (without

PAGE 1 GATE 2 Part No. 23001125 SWING GATE CTROLLER INSTALLATI GUIDE Page 2 GATE 2 Code No. 23001125 Electronic Control Board for use with SEA Hydraulic or Electro-mechanical swing gate operators (without

RC 195 Receiver-Controller

Document No. 129-082 RC 195 Receiver-Controller Product Description The POWERS RC 195 Receiver-Controller is a pneumatic instrument that receives one, two or three pneumatic inputs. It produces a pneumatic

Document No. 129-082 RC 195 Receiver-Controller Product Description The POWERS RC 195 Receiver-Controller is a pneumatic instrument that receives one, two or three pneumatic inputs. It produces a pneumatic

PIRANHA I & 2 OPERATION GUIDE

PIRANHA I & 2 OPERATION GUIDE Thank You Thank you for purchasing a Piranha fishfinder from Humminbird, America s #1 Manufacturer of quality consumer marine electronics WARNING! This device should not be

PIRANHA I & 2 OPERATION GUIDE Thank You Thank you for purchasing a Piranha fishfinder from Humminbird, America s #1 Manufacturer of quality consumer marine electronics WARNING! This device should not be

SC 110 Autopilot Installation and Operations Manual _A

SC 110 Autopilot Installation and Operations Manual 531760-3_A Thank You Thank you for choosing Humminbird, the #1 name in Fishfinders. Humminbird has built its reputation by designing and manufacturing

SC 110 Autopilot Installation and Operations Manual 531760-3_A Thank You Thank you for choosing Humminbird, the #1 name in Fishfinders. Humminbird has built its reputation by designing and manufacturing

How to calibrate the formaldehyde sensor within a PPMonitor Wireless Unit:

How to calibrate the formaldehyde sensor within a PPMonitor Wireless Unit: Please read this document thoroughly before attempting to check or adjust the calibration of the formaldehyde sensor within the

How to calibrate the formaldehyde sensor within a PPMonitor Wireless Unit: Please read this document thoroughly before attempting to check or adjust the calibration of the formaldehyde sensor within the

BUBBLER CONTROL SYSTEM

BUBBLER CONTROL SYSTEM Description: The HDBCS is a fully automatic bubbler system, which does liquid level measurements in water and wastewater applications. It is a dual air compressor system with, air

BUBBLER CONTROL SYSTEM Description: The HDBCS is a fully automatic bubbler system, which does liquid level measurements in water and wastewater applications. It is a dual air compressor system with, air

GRI-1300/1350Li. User Manual

User Manual GRI-1300/1350Li Your Cart Tek caddy cart was thoroughly quality control checked and road tested before being shipped to your address. We do everything possible to assure that your caddy is

User Manual GRI-1300/1350Li Your Cart Tek caddy cart was thoroughly quality control checked and road tested before being shipped to your address. We do everything possible to assure that your caddy is

RAM 4021-DPX Operation Manual

RAM 4021-DPX Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS ABL 4021-DPX / RAM 4021-DPX For Your Safety... 3 Description... 3 Setup Mode... 4 Lights/Alarms... 4 Operation...

RAM 4021-DPX Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS ABL 4021-DPX / RAM 4021-DPX For Your Safety... 3 Description... 3 Setup Mode... 4 Lights/Alarms... 4 Operation...

ST7000 Plus Autopilot Control Unit Owner s Handbook

ST7000 Plus Autopilot Control Unit Owner s Handbook Document number: 81118_1 Date: 20 January 1999 Preface i Raytheon Electronics, as part of its commitment to continuous improvement and updating, reserve

ST7000 Plus Autopilot Control Unit Owner s Handbook Document number: 81118_1 Date: 20 January 1999 Preface i Raytheon Electronics, as part of its commitment to continuous improvement and updating, reserve

Manual Leveling Control Installation/Operation

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

ST5000+ Sterndrive & Hydraulic Autopilots. Owner s handbook. English Date: Document number: EN 2006 Raymarine UK Limited

ST5000+ Sterndrive & Hydraulic Autopilots Owner s handbook English Date: 09-2006 Document number: 81132-7-EN 2006 Raymarine UK Limited Preface i Hydraulic Sterndrive Rudder Reference Unit (Optional for

ST5000+ Sterndrive & Hydraulic Autopilots Owner s handbook English Date: 09-2006 Document number: 81132-7-EN 2006 Raymarine UK Limited Preface i Hydraulic Sterndrive Rudder Reference Unit (Optional for

RAM 4021 Operation Manual

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For your safety...3 Description...3 Set-up mode...4 Annunciator lights/alarms...4 Operation...5 Calibration...6

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For your safety...3 Description...3 Set-up mode...4 Annunciator lights/alarms...4 Operation...5 Calibration...6

Model 106 DPI "Micro-switch" Installation and Operating Instructions

Mid-West Instrument Model 106 DPI "Micro-switch" Installation and Operating Instructions BULLETIN NO. IM116DPImicro/09A Replaces --- INSPECTION Before installation carefully check the Model Number on each

Mid-West Instrument Model 106 DPI "Micro-switch" Installation and Operating Instructions BULLETIN NO. IM116DPImicro/09A Replaces --- INSPECTION Before installation carefully check the Model Number on each

IBU3 Manual Addendum 1

This addendum covers the follow items. Connection of airsoft micro switch Connection of Taigen airsoft recoil units Selecting airsoft mode Settings for clutch style gearboxes Motor enable selection Confirmation

This addendum covers the follow items. Connection of airsoft micro switch Connection of Taigen airsoft recoil units Selecting airsoft mode Settings for clutch style gearboxes Motor enable selection Confirmation

OC Panel High Limit Aquastat Kit, Manual Reset p/n

OC Panel High Limit Aquastat Kit, Manual Reset p/n 233202 Instruction Sheet APPLICATION The OC (Option Control) Panel High Limit Aquastat Kit provides electronic temperature sensing in a UL limit-rated

OC Panel High Limit Aquastat Kit, Manual Reset p/n 233202 Instruction Sheet APPLICATION The OC (Option Control) Panel High Limit Aquastat Kit provides electronic temperature sensing in a UL limit-rated

INSTALLATION PROCEDURE 1/4 & 1/8 MILE PERMANENT TRACK

INSTALLATION PROCEDURE 1/4 & 1/8 MILE PERMANENT TRACK 1) Unpack all of the equipment and immediately inspect for shipping damage. Damages should be immediately reported to the carrier and noted on the

INSTALLATION PROCEDURE 1/4 & 1/8 MILE PERMANENT TRACK 1) Unpack all of the equipment and immediately inspect for shipping damage. Damages should be immediately reported to the carrier and noted on the

Ventam 85 Installation & Commissioning Instructions

Ventam Systems Ltd Unit D4 Seedbed Business Centre Vanguard Way Shoeburyness Essex SS3 9QY Phone 01702 382 307 Fax 01702 382 340 Ventam 85 Installation & Commissioning Instructions 1 General The Ventam

Ventam Systems Ltd Unit D4 Seedbed Business Centre Vanguard Way Shoeburyness Essex SS3 9QY Phone 01702 382 307 Fax 01702 382 340 Ventam 85 Installation & Commissioning Instructions 1 General The Ventam

Stand-Alone Bubble Detection System

Instruction Sheet P/N Stand-Alone Bubble Detection System 1. Introduction The Bubble Detection system is designed to detect air-bubble induced gaps in a bead of material as it is being dispensed. When

Instruction Sheet P/N Stand-Alone Bubble Detection System 1. Introduction The Bubble Detection system is designed to detect air-bubble induced gaps in a bead of material as it is being dispensed. When

Operator manual. Simrad AP50 Autopilot. A brand by Navico - Leader in Marine Electronics.

Operator manual Simrad AP50 Autopilot English Sw.1.3 www.simrad-yachting.com A brand by Navico - Leader in Marine Electronics Simrad AP50 Autopilot About this document Rev. A Rev. B Rev. C Rev. D Rev.

Operator manual Simrad AP50 Autopilot English Sw.1.3 www.simrad-yachting.com A brand by Navico - Leader in Marine Electronics Simrad AP50 Autopilot About this document Rev. A Rev. B Rev. C Rev. D Rev.

2. USER INSTRUCTION. Table of contents: Pg.1/14 N:\FAP-2000: LWP

Pg.1/14 2. USER INSTRUCTION. Table of contents: 2.1 SHORT PANEL DESCRIPTION...... Pg.2 2.2 AUTOPILOT TAKE-OVER & MODE SELECTION....... Pg.3 2.3 AUTOPILOT FUNCTIONS....... Pg.3 2.4 THE SPECIAL FUNCTION

Pg.1/14 2. USER INSTRUCTION. Table of contents: 2.1 SHORT PANEL DESCRIPTION...... Pg.2 2.2 AUTOPILOT TAKE-OVER & MODE SELECTION....... Pg.3 2.3 AUTOPILOT FUNCTIONS....... Pg.3 2.4 THE SPECIAL FUNCTION

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units Digital Range

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units Digital Range Models: DS 126 Single Pump / Single System DT 126 Twin Pump / Single System DS 160

Installation, Operation and Maintenance Instructions for Electronically Controlled Pressurisation Units Digital Range Models: DS 126 Single Pump / Single System DT 126 Twin Pump / Single System DS 160

RAM Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

Proportional Pressure-Relief Cartridge Valve, Size 2...4

Proportional Pressure-Relief Cartridge Valve, Size... Q max = l/min, p max = 3 bar Direct acting, electrically operated 1 Description proportional pressure-relief valves are direct acting screw-in cartridges

Proportional Pressure-Relief Cartridge Valve, Size... Q max = l/min, p max = 3 bar Direct acting, electrically operated 1 Description proportional pressure-relief valves are direct acting screw-in cartridges

444C DUAL PERFORMANCE VALUE PACK

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

RAM Operation Manual

RAM 4021-1 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-1 For Your Safety... 2 Description... 2 Setup Mode... 3 Lights/Alarms... 3 Operation... 4 Calibration...

RAM 4021-1 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-1 For Your Safety... 2 Description... 2 Setup Mode... 3 Lights/Alarms... 3 Operation... 4 Calibration...

MANUAL. Simrad AP26 and AP27 Autopilots

MANUAL Simrad AP26 and AP27 Autopilots This page is intentionally left blank Instruction manual Instruction Manual This manual is intended as a reference guide for operating and correctly installing the

MANUAL Simrad AP26 and AP27 Autopilots This page is intentionally left blank Instruction manual Instruction Manual This manual is intended as a reference guide for operating and correctly installing the

NIV EAU MATIC ST User Manual Made in Canada

NIV EAU MATIC ST User Manual Made in Canada www.niveaumatic.com info@niveaumatic.com -2- Table of contents Introduction Section 1 Page 4 Installation Section 2 Pages 5 to 10 2.1 Control box 2.2 Sensor

NIV EAU MATIC ST User Manual Made in Canada www.niveaumatic.com info@niveaumatic.com -2- Table of contents Introduction Section 1 Page 4 Installation Section 2 Pages 5 to 10 2.1 Control box 2.2 Sensor

Contents. Chapter 1 Important information Chapter 4 Pilot views Chapter 5 Pilot modes Chapter 2 Handbook information...

Contents Chapter 1 Important information... 7 Safety notices... 7 TFT LCD Displays... 8 Water ingress... 8 Disclaimers... 8 EMC conformance... 8 Suppression ferrites... 9 Connections to other equipment...

Contents Chapter 1 Important information... 7 Safety notices... 7 TFT LCD Displays... 8 Water ingress... 8 Disclaimers... 8 EMC conformance... 8 Suppression ferrites... 9 Connections to other equipment...

Installation and Instructions 2. Product Features 3-6. Key Pad Functions 7. Distributor Information Programming Guide 8. Master Programming Guide 9-14

Installation and Instructions 2 Product Features 3-6 Key Pad Functions 7 Distributor Information Programming Guide 8 Master Programming Guide 9-14 Dimensional Drawing 15 D-STC & D-SMM Valve Assembly 16-17

Installation and Instructions 2 Product Features 3-6 Key Pad Functions 7 Distributor Information Programming Guide 8 Master Programming Guide 9-14 Dimensional Drawing 15 D-STC & D-SMM Valve Assembly 16-17

ST1000 Plus & ST2000 Plus Tiller Pilots Owner s Handbook. Document number: Date: June 2001

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. ST1000 Plus & ST2000 Plus Tiller Pilots

Distributed by Any reference to Raytheon or RTN in this manual should be interpreted as Raymarine. The names Raytheon and RTN are owned by the Raytheon Company. ST1000 Plus & ST2000 Plus Tiller Pilots

GNX 20/21. Owner s Manual

GNX 20/21 Owner s Manual Table of Contents Introduction...1 Device Overview... 1 Using the Race Timer... 1 Profiles... 1 Selecting a Profile... 1 Restoring Profiles to their Default Settings... 1 Instrument

GNX 20/21 Owner s Manual Table of Contents Introduction...1 Device Overview... 1 Using the Race Timer... 1 Profiles... 1 Selecting a Profile... 1 Restoring Profiles to their Default Settings... 1 Instrument

RAM 4021-PR. Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021-PR Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-PR For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4

RAM 4021-PR Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-PR For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4

Table of Contents. Sensor Calibration and Troubleshooting CDS4000 CO 2. Introduction 1. Handling Information. Calibration 2.

FANs 216, 1628.3 Technical Bulletin CDS4000 Issue Date 0797 CDS4000 CO 2 Sensor Calibration and Troubleshooting Table of Contents Introduction 1 Handling Information 1 Calibration 2 Preparation 2 Cautions

FANs 216, 1628.3 Technical Bulletin CDS4000 Issue Date 0797 CDS4000 CO 2 Sensor Calibration and Troubleshooting Table of Contents Introduction 1 Handling Information 1 Calibration 2 Preparation 2 Cautions

BRILLIANT WONDERS LED BUBBLERS INSTALLATION INSTRUCTIONS CMP SERIES. Brilliant Wonders LED BUBBLERS

R BRILLIANT WONDERS LED BUBBLERS INSTALLATION INSTRUCTIONS CMP 25503 SERIES Brilliant Wonders LED BUBBLERS TABLE OF CONTENTS 1. Product Overview....3 1.1 Specifications. 3 1.2 Packing List...3 2. System

R BRILLIANT WONDERS LED BUBBLERS INSTALLATION INSTRUCTIONS CMP 25503 SERIES Brilliant Wonders LED BUBBLERS TABLE OF CONTENTS 1. Product Overview....3 1.1 Specifications. 3 1.2 Packing List...3 2. System

RAM Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

BUBBLER CONTROL SYSTEM

BUBBLER CONTROL SYSTEM Description: The LDBCS is a fully automatic bubbler system, which does liquid level measurements in water and wastewater applications. It is a dual air compressor system with, air

BUBBLER CONTROL SYSTEM Description: The LDBCS is a fully automatic bubbler system, which does liquid level measurements in water and wastewater applications. It is a dual air compressor system with, air

AFDXXX(X)AC Series Operators Manual Please read this manual thoroughly before attempting to operate your water maker.

AFDXXX(X)AC Series Operators Manual Please read this manual thoroughly before attempting to operate your water maker. E & O E Danger High Voltage AFDXXX(X) Series water makers operate on a 240vAC electricity

AFDXXX(X)AC Series Operators Manual Please read this manual thoroughly before attempting to operate your water maker. E & O E Danger High Voltage AFDXXX(X) Series water makers operate on a 240vAC electricity

Inverse Proportional Pressure-Relief Cart., Size 2 4

Inverse Proportional Pressure-Relief Cart., Size Q max = l/min, p max = 35 bar Direct acting, electrically operated Description Compact construction for cavity type AL 3/-6 UNF Operated by a proportional

Inverse Proportional Pressure-Relief Cart., Size Q max = l/min, p max = 35 bar Direct acting, electrically operated Description Compact construction for cavity type AL 3/-6 UNF Operated by a proportional

Software updates Check the website for the latest software releases for your product.

STBY Trademark and patents notice Autohelm, hsb 2, RayTech Navigator, Sail Pilot, SeaTalk, SeaTalk NG, SeaTalk HS and Sportpilot are registered trademarks of Raymarine UK Limited. RayTalk, Seahawk, Smartpilot,

STBY Trademark and patents notice Autohelm, hsb 2, RayTech Navigator, Sail Pilot, SeaTalk, SeaTalk NG, SeaTalk HS and Sportpilot are registered trademarks of Raymarine UK Limited. RayTalk, Seahawk, Smartpilot,

icreasepro Creaser Operators Manual

6-2013 Version 3.0 icreasepro Creaser Operators Manual WWW.MBMCORP.COM 800-223-2508 TABLE OF CONTENTS SPECIFICATIONS.1a SAFETY PROCEDURES/CARE & MAINTENANCE..1b COMPONENT IDENTIFICATION 2 TOUCH SCREEN

6-2013 Version 3.0 icreasepro Creaser Operators Manual WWW.MBMCORP.COM 800-223-2508 TABLE OF CONTENTS SPECIFICATIONS.1a SAFETY PROCEDURES/CARE & MAINTENANCE..1b COMPONENT IDENTIFICATION 2 TOUCH SCREEN

PropaGator Autonomous Surface Vehicle

PropaGator Autonomous Surface Vehicle Andrew Wegener December 4, 2012 University of Florida Department of Electrical and Computer Engineering EEL 5666C IMDL Final Report Instructors: A. Antonio Arroyo,

PropaGator Autonomous Surface Vehicle Andrew Wegener December 4, 2012 University of Florida Department of Electrical and Computer Engineering EEL 5666C IMDL Final Report Instructors: A. Antonio Arroyo,

Procedure Troubleshooting the Interconnect Cables

Procedure 6.1 - Troubleshooting the Interconnect Cables Troubleshooting the upper interconnect cable 1. Remove the display housing per Procedure 7.13. Disconnect the upper interconnect cable from the upper

Procedure 6.1 - Troubleshooting the Interconnect Cables Troubleshooting the upper interconnect cable 1. Remove the display housing per Procedure 7.13. Disconnect the upper interconnect cable from the upper

Proportional Pressure-Relief Cartridge Valve, Size 2...4

Proportional Pressure-Relief Cartridge Valve, Size... Q max = l/min (6 gpm), p max = bar (58 psi) Direct acting, electrically operated Description proportional pressure-relief valves are direct acting

Proportional Pressure-Relief Cartridge Valve, Size... Q max = l/min (6 gpm), p max = bar (58 psi) Direct acting, electrically operated Description proportional pressure-relief valves are direct acting