Digital Depth Sounder Display Installation and Operation Manual. time for you to react.

|

|

|

- Alberta Alexander

- 6 years ago

- Views:

Transcription

1 DF1000D Digital Depth Sounder Display Installation and Operation Manual WARNING!!!! This depth sounder should not be used as a navigational aid to prevent grounding, boat damage, or personal injury. Always operate the boat at slow speeds in unfamiliar water, or if you suspect shallow water or submerged objects, as water depth may change too quickly to allow time for you to react. TRANSDUCER SELECTION The transducer supplied with the DF1000D is suitable for installation and operation on most boats. For optimal performance the transducer should be mounted to the transom of the boat as per the installation instructions supplied with the transducer installation instructions. On fiberglass hulls (non-cored) and some aluminum hulls it can be glued to the inside of the hull, but this type of installation will reduce the performance of the DF1000D slightly. Some boats may require a specialized transducer. If after completely reviewing the transducer installation instructions supplied with the transducer you find that the supplied transducer is not appropriate for your vessel, please contact NMP at , or visit us on the internet at for exchange information. You may exchange your new and unused transducer for another type, but keep in mind that some transducers may have additional costs. PARTS AND TOOLS LIST Included Transom/In-Hull Transducer Parts Supplied in Packaging Before installing your DF1000D Depth Sounder, please ensure that the following parts are included in the packaging: DF1000D Depth Sounder Display Flush Mount Bracket and Hardware Power Cable Attached to the Unit Warranty Card If any items are missing or damaged, please contact our Customer Service Department at Tools and Supplies Required for Installation 2 Hole Saw and Drill Wire Connectors Suitable for Connecting the Power Wire to Your Vessel Wire Cutting/Crimping Tool Marine Sealant DISPLAY INSTALLATION Installation of the DF1000D Display 1. Find a location on the boat that will allow clear viewing of the LCD Display. Please keep in mind that the wires for the transducer and power must reach the mounting location. 2. After finding the right location for the display, mark a 2-inch hole. 3. Check behind the desired mounting location for any cables or wiring which could be damaged, then cut out the 2-inch hole and seal any exposed wood with a marine sealant. 4. Insert the display from the front of the panel, and install the bracket and locking nut from the rear of the panel (see Figure 1). Make sure that the face of the display is rotated upright and aligned to your satisfaction for easy viewing from the vessel s helm. Figure 1 Figure 2 Install the transducer before installing the display to ensure that the transducer cable is long enough to reach your desired mounting location. Read ALL the instructions completely before proceeding with the installation. MB01 The DF1000D can also be surface mounted using NMP s exclusive MB01 Adjustable Surface Mount Bracket (see Figure 2). Please see your local retailer, or contact NMP s by phone , or online at: for purchase information. You must attached the extension rod to the mounting stud on the back of the DF1000D display before inserting the display into the MB Extension Rod

2 Installing the Face and Bezel Figure 3 1. Place the face over the display (Figure 3B) making sure to line up the cut outs on the face with the notches on the display. 2. While holding the bezel (Figure 3A) place it over the display and turn counterclockwise until the bezel locks into place. Wiring of the Power Cable A B The DF1000D has no ON/OFF switch. Therefore, you will need to wire it to a power source that will turn the unit on as power is applied. The Key Switch or an ON/OFF power switch will be suitable for powering the DF1000D. 1. Connect the BLACK wire to the negative (-) battery terminal or suitable ground (see Figure 4). Figure 4 + (red) 2. Connect the RED wire to a positive (+) 12 Volt switchable power source (key switch, on/off switch) (see Figure 4). - (black) Connecting the Transducer Cable Figure 5 To connect the transducer cable to the display, align the plug from the transducer with the plug from the display and press together as per figure Figure 5. OPERATING THE DF1000D The DF1000D s auto-ranging, auto-sensitivity features means that you never have to worry about adjustments. Simply turn the power on, and your ready to go. The DF1000D emits sound signals that travel through water, and then calculates the amount of time that elapsed while the signal traveled down to the bottom and returned back to the transducer. This time is calculated by the DF1000D and displayed as a depth reading. Extremely dirty water, very soft bottom, high speeds, deep water, or a combination of the above will result in incomplete or inaccurate readings. Under these conditions variable readings or (Figure 6) will be displayed. NOTICE!!!! All user selected settings will be retained when the power is turned off, therefore they will not need to be reset when the power is turned back on. Setting the Units of Measure The UNITS of measure for depth readout and alarm functions can be set in 4 easy steps. The two settings available are Feet (FT) and Meters (M). To Set the Units: 1. Press and hold the "UP" and "DOWN keys at the same time for 5 seconds until the units indicator (FT or M) blinks (Figure 7). 2. To set the units to FEET press the UP key. FT will flash on the Display. 3. To set the units to METERS press the DOWN key. M will flash on the Display. 4. The display will return to the normal operation mode automatically after five seconds. Figure 6 Figure 7 Figure 8 Setting the Shallow Water Alarm The shallow alarm function can be set for depths ranging from 3 to 200 feet and triggers an alarm when the depth is less than the setting. To set the SHALLOW ALARM (upper alarm): 1. Press the "UP" key located on the front of the DF1000D display (Figure 8). The current alarm setting will be displayed on the display. "000" is the default setting. 2. Pressing the "UP" key will increase the selected value. Pressing the "DOWN" key will reduce the value. Pressing and releasing the key will change the value in 1-foot increments per second. Holding down the key will change the value in 9 foot increments per second. 3. After your selection is made, the display will return to normal operation after 5 seconds. 4. The " "and " " icons will now be present. When triggered, the alarm sounds an audible "alarm" for ten seconds while flashing the warning LED and the " "and icons on the display. After 10 seconds the audible alarm mutes and the warning LED and the " " and " " icons continue to blink until the depth increases, or the alarm is reset. To reset the alarm repeat step 1 thru 4. Setting the Deep Water Alarm The DEEP alarm function can be set for depths ranging from 3 to 200 feet and triggers an alarm when the depth is more than the setting. To set the DEEP ALARM (lower alarm): 1. Press the "DOWN" key located on the front of the DF1000D display (Figure 9). The current alarm setting will be displayed on the display. "000" is the default setting. 2. Pressing the "UP" key will increase the selected value. Pressing the "DOWN" key will reduce the value. Pressing and. Figure 9-2 -

3 releasing the key will change the value in 1-foot increments per second. Holding down the key will change the value in 9 foot increments per second. 3. After your selection is made, the unit will return to normal operation after 5 seconds. 4. The " "and " " icons will now be present When triggered, the alarm sounds an audible "alarm" for ten seconds while flashing the warning LED and the " "and icons on the display. After 10 seconds the audible alarm mutes and the warning LED and the " " and " " icons continue to blink until the depth increases, or the alarm is reset. To reset the alarm repeat step 1 thru 4. Setting the Keel Offset The Keel Offset feature is used to adjust the depth readings displayed by the DF1000D to compensate for the depth of the water required for your vessel to operate safely. For Example: If your boat s draft is 3 feet, the Keel Offset feature should be set to 3 feet. The DF1000D will then subtract 3 feet from the actual depth reading, and display this figure as the depth. If the water depth is 5 feet and the Keel Offset is set to 3 feet, the depth will be displayed as 2 feet, indicating to the operator that there is 2 feet of safe operating water. Figure 10 The maximum Keel Offset setting is 20 FT (6.1 M), settable in.1 (1/10 th ) Foot or Meter increments. The DF1000D will read --- when a negative value occurs due to the Keel Offset Subtraction. To set the KEEL OFFSET: 1. Press and hold the UP and DOWN keys at the same time for 3 seconds. When K/O begins flashing in the upper left hand corner of the display, release the keys. (see figure 10). Press the "UP key to increase the Keel Offset value. Press the "DOWN" key to reduce the value. 3. The display will return to the normal operation mode after five seconds if no keys are pressed. 4. K/O will remain illuminated in the top left hand corner indicating that the depth readings are adjusted to the Keel Offset setting. TROUBLESHOOTING WARNING!!!! If you are unsure of the Draft of your vessel, please consult with the vessel s manufacturer before setting the Keel Offset. An improper Keel Offset setting can cause accidently grounding of the vessel and may cause severe damage to the vessel and it s passengers. There are no user repairable parts within the DF1000D. Attempting to repair the unit yourself will only void the warranty. If you have a problem with your DF1000D, consult the following troubleshooting guide. If this does not remedy your problem, please contact NMP at for assistance. WARNING: Disassembly of the electronic components within this unit may result in exposure to lead in the form of solder, which is known to the state of California to cause cancer, birth defects, and other reproductive harm. The DF1000D does not turn on. 1. Check the inline fuse located on the main power supply to the unit. If it is blown, replace it with a 1 amp, normal blow fuse. Clean all corrosion from the fuse housing, and replace the fuse holder assembly if necessary. 2. Check the power cable connection. Be sure that the unit is connected to a known power source: RED wire to positive, BLACK wire to negative or ground. 3. Ensure that the power source is powered using a test light, or some other reliable form of testing 12 volt power. 4. If you are sure that the unit is receiving power and is still not turning on, please refer to the warranty and service section. The Bottom Reading is Random, Flashing, or Appears as --- on the display. 1. The depth is less than 2.5 feet or greater than 200 feet. Operate the unit under normal operating specifications and check to see if it operating properly. 2. If this condition occurs only at certain speeds, then a transducer adjustment is needed. Refer to the Helpful Hints for Transducer Installation section below. Refer to the Transducer Installation Instructions for adjustment procedures. 3. Under certain circumstances the DF1000D may not perform at the best of its ability. Extremely dirty water, very soft bottom, high speeds, deep water, or a combination of the above will result in incomplete or inaccurate readings. Please refer to the Transducer Installation Instructions to minimize the effects of these conditions. 4. If the transducer is transom mounted check to make sure that the transducer is not kicked-up. To prevent damage to the transducer, it will automatically release from the mounting bracket (kick-up) when it is impacted. If this occurs refer to the Transducer Installation Instructions to reset the transducer for normal operation. If this happens frequently make sure that the trailer or boat lift supports do not interfere with the transducer during loading and unloading. 5. Check the transducer cable connection on the back of the unit. Make sure that the connection is made as per the instructions in the Connecting the Transducer section of this manual. 6. Contact NMP at for assistance if you are unable to correct the problem. Helpful Hints for Transducer Installation (Transom Mounting) 1. Make sure the transducer is not mounted in any area where the water flow is interrupted by propeller turbulence or aerated water. If standing at eye level, behind the transducer and looking forward along the bottom of the boat hull there should NOT be any strakes, chimes, steps, or hull fittings inline with the transducer. If there are any of these obstructions, the transducer will need to be relocated to achieve optimal performance. The transducer CAN NOT be transom mounted on a Stepped-Hull vessel, it must only be in-hull mounted. 2. Make sure that the leading edge (bow - side closest to the bow of the boat) of the transducer extends at least 1/8 (3 mm) below the bottom of the hull. Also make sure that the trailing edge (stern - side furthest from the bow of the boat) is 1/16 to 1/18 (1-3 mm) below the leading edge (Figure 11) Figure 11 slight angle

4 Helpful Hints for Transducer Installation (In-Hull Mounting) 1. The hull must be made out of solid fiberglass or a maximum 1/8 (3 mm) aluminum. The unit will not work through wood, plastic, or any other composite material. 2. The glue in location must be in direct contact with the water at all times during operation. The transducer CAN NOT be mounted in any area where the water flow is interrupted by propeller turbulence or aerated water. It MUST NOT be mounted behind any strakes, chimes, steps, or hull fittings that will disrupt the flow of clean water to the transducer (in line with the mounting location of the transducer and the bow of the boat). If there are any of these obstructions, the transducer will need to be relocated to achieve optimal performance. 3. If mounting in-hull on a stepped hull vessel, the transducer must be mounted in a location where there are no steps forward of the transducer (between the transducer mounting location and the bow of the boat). Keep in mind that the glue in location must be in direct contact with the water at all times during operation or incorrect depth readings will occur. The Transducer Cable Supplied with the Transducer is Too Short for My Installation, Can It Be Extended YES: To extend the transducer cable: 1. Using a wire cutter, cut the cable on the transducer side 3 (76 mm) from the plug and the cable on the display side 1 (25 mm) from the plug. 2. At both cuts, strip back the rubber cable cover 1 (25 mm) exposing the three internal wires (blue, white, and bare). 3. Using a soldering iron, solder the desired length extension cable (available at a boating supply store or by calling ) between the depth sounder display and the transducer. Be certain that the blue, white and bare wires are connected properly between the depth sounder display and the transducer and make sure the colors are consistantly matched throughout the splice. 4. Using electrical tape, or heat shrink tubing make certain that the soldered connections are completely sealed and protected against accidental electrical interference. Specifications Colors White/Black Interchangeable Mounting Location In-Dash, Surface Mount (MB01) Case Dimensions 2" Dia, 3.4" Depth LCD Window Size 1.65" x 0.87" Button Type Waterproof Membrane Backlighting Green SoftGlow Readout , Power Requirement 11-14Vdc, 200mA max Current Drain 40mA, Nominal Units of Measure Feet and Meters Transmit Power 250W (max) Depth Range Max 200 Ft (60.7 M) Depth Range Min 2.5 Ft (.7 M) Alarm Signaling Visual and Audible Audible Alarm Location Internal Upper Alarm Range 3-200ft, Full Range ( M) Lower Alarm Range 3-200ft, Full Range ( M) Keel Offset 0-20Ft,.1 Ft Increments (0-6.1 M) Options and Accessories (available at Adjustable Surface Mounting Bracket (P/N - MB01) Alloy Bezel Kits - Chrome P/N - BZ05 - Brushed Silver P/N - BZ04 - Gold P/N - BZ03 NORCROSS MARINE PRODUCTS, INC 2-YEAR LIMITED WARRANTY To be eligible for warranty coverage your product must have a copy of the Warranty Registration Card on file with NorCross Marine Products, Inc. (NMP), so be sure to submit the included registration card within 10 days of purchase. You may also register on our website. NorCross Marine Products, Inc. (NMP) warrants, to the original purchaser, this product to be free from defects in materials and workmanship for Two (2) Years from the date of purchase. If the unit fails to perform as described in the product s written specifications, due to a defect in materials or workmanship, we will repair it free of charge to the customer for parts or labor. The customer, however, is responsible for any costs associated with returning the unit to NorCross. This warranty is void if damage or malfunction is due to abuse, misuse, accident, failure to reasonably maintain, improper installation or use, or unauthorized alteration or repairs. Norcross retains the exclusive right to repair or replace the unit at its sole discretion, and holds this right as the exclusive remedy available to the customer against NorCross for any defect, malfunction, or non-conformity concerning the product, or for any loss or damage resulting from any other cause whatsoever. Norcross will respond to all warranty claims within a reasonable time after receipt of the unit from the original purchaser, with such response time not to exceed thirty days without written notification of delay to customer. To be eligible for the warranty a copy of the original sales receipt is required as the proof of purchase and a copy of the Warranty registration card must also be on file with NMP. To Obtain Warranty Service: 1. Contact NMP via telephone ( ) or (customerservice@norcrossmarine.com) to obtain a Return Authorization Number. 2. Securely pack the unit along with a copy of the original sales receipt, a description of the defect. Please be sure to include your name, address, address, and a daytime phone number. 3. Write your assigned Return Authorization Number from Step 1 on the outside of the box. 4. Send prepaid via insured and traceable transportation to: NorCross Marine Products, Inc., Warranty Department, 6450 Kingspoint Parkway, Suite 6, Orlando, FL You can check the status of your return by sending an to customerservice@norcrossmarine.com. Be sure to include your name and Return Authorization Number in the Kingspoint Parkway, Suite 6 Orlando, FL (p) Norcross Marine Products, Inc., All rights reserved. All specifications are subject to change without notice.

5 MT01 Transom/In-Hull Marine Transducer Transducer Installation and Adjustment Manual The MT01 Transom/In-Hull Transducer is suitable for installation and operation on most boats. For optimal performance the transducer should be mounted to the transom of the boat as per the installation instructions. On fiberglass hulls (non-cored) and some aluminum hulls it can be glued to the inside of the hull, but this type of installation will reduce the performance of the depth sounder slightly. Some boats may require a specialized transducer. If after completely reviewing the transducer installation instructions you find that the supplied transducer is not appropriate for your vessel, please contact NMP at , or visit us on the internet at for exchange information. You may exchange your new and unused transducer for another type, but keep in mind that some transducers may have additional costs. PARTS AND TOOLS LIST Before installing the MT01, please ensure that the following parts are included in the packaging: Transducer with 25 of Cable and Plug Transducer Support Bracket with Attached Kick-Up Bracket (2) Tapered Plastic Shims (2) Cable clamps Clam Shell Cable Cover (2) #10 x 1.25 self-tapping screws (2) #6 x.25 self-tapping screws If any items are missing or damaged, please contact our Customer Service Department at Tools and Supplies Required for Installation Electric Drill 1/4 (6 mm) drill bit, hole saw or spade bit (cable thru-hull pass through) 1/8 (3mm) drill bit (cable clamp and clam shell cover mounting holes) 9/64 (4 mm) drill bit (Kick-Up Bracket mounting holes) Marine Sealant Straight Edge Screwdrivers Pencil Tie Wraps Water based antifouling paint (transom mount installation) Plastic Bag (in-hull installation) Petroleum Jelly (in-hull installation) 2 Part Epoxy Adhesive (in-hull installation) 30 Grit Sandpaper (in-hull installation) Safety Goggles Dust Mask Masking Tape Install the transducer before installing the display to ensure that the transducer cable is long enough to reach your desired mounting location. If the transducer cable needs to be extended, please follow the instructions in the Troubleshooting Guide before starting the installation. Read ALL the instructions completely before proceeding with the installation. Figure 1 4 Minimum TRANSOM MOUNTING THE TRANSDUCER Does the Installation Vessel Have These Characteristics? 1. Outboard, inboard/outboard, single inboard, or jet-drive propulsion. 2. Hull deadrise angle below Transom angle from NOTICE!!!! If the answer to any of these questions is no, skip to the In-Hull Mounting Instructions within this manual or call to inquire about exchanging the transducer. Mounting Location To obtain the best performance, the transducer should be mounted in a location where the water flow is aeration and turbulence-free. Try to mount the transducer as close to the centerline of the boat as possible. On a single drive boat mount on the starboard side at least 4 (101 mm) beyond the radius of the propeller (see Figure 1 above). On a twin drive boat mount the transducer between the drives making certain that the transducers not directly in front of either drive or propeller. On an inboard boat mount the transducers far to the port or starboard as possible so that the propeller turbulence does not effect the performance of the sensor CAUTION!!!! Do not mount the transducer in an area of turbulence or bubbles: Near water intake or discharge openings. Behind strakes, struts, fittings or hull irregularities. Behind eroding paint, hull deformities, or marine growth Avoid mounting the transducer where the boat may be supported during trailering, launching, hauling, or storage.

6 Assembling and Mounting 1. With the Locking Tab in the up position, align the transducer and bracket as per Figure 2 and slide the transducer into the Pivot Bracket until it cannot slide any further. (minimal force is required) 2. Press the Locking Tab down against the Pivot Bracket until it locks firmly into place. 3. Tape the template inserted in this manual against the hull as per Figure At the desired mounting location, position the template so the arrow at the bottom is aligned with the bottom edge of the vessel making certain that the template is parallel to the waterline of the vessel. 5. Using a 9/64" (4 mm) drill bit, drill two holes 7/8" (22 mm) deep at the locations indicated on the template marked with an X. To prevent drilling too deeply, wrap masking tape around the bit 7/8 (22 mm) from the point. To minimize surface cracking on fiberglass hulls use a chamfer or countersink bit. If either is not available, start drilling with a 1/4 (6 mm) bit to a depth of 1/16" (1 mm), then finish the hole with the 9/64 (4mm) bit. 6. Apply a marine sealant to the threads of the two #10 x 1-1/4" self-tapping screws and screw the bracket to the hull. DO NOT tighten the screws completely until you position the transducer as per the next section. Positioning The bracket is designed for a standard 13 transom angle. To determine if the plastic shim is needed, position the transducer at the desired location. Using a straight edge, compare the underside of the transducer relative to the underside of the hull. The stern (trailing edge) of the transducer should be 1/16 1/8" (1 3 mm) Align the included shims (Figure 4) to achieve a slight angle as per Figure 5 below. To prevent aeration, NEVER position the transducer is a manner that the Leading Edge (bow) is LOWER than the Trailing Edge (stern). Mounting Bracket below the bow (leading edge) of the sensor. Shim Figure 4 C O R R E C T I N C O R R E C T shim with taper down Figure 5 Figure 2 Pivot Bracket Tape Sensor Locking Tab Figure 3 Template Alignment Arrow Hull Bottom Pivot Bracket slight angle parallel Reversed Angle Too Steep Of An Angle Propeller Tightening Slide the transducer up or down to provide a projection of 1/8 inches (3 mm) below the hull bottom and then tighten the screws. Do not allow the transducer to extend more than 1/8 (3 mm) of an inch below the bottom of the boat as this will create increased aeration and turbulence. Figure 6 Cable Routing Route the transducer cable over the transom, through a deck or splash-well drain hole or through a new hole drilled in the transom. 1. If a new hole is required, it MUST be drilled well above the waterline. 2. Mark the desired location with a pencil 3. Check for obstructions behind the desired location inside the hull. 4. Drill a hole through the transom using a 3/4 or 19 mm hole saw or spade bit. 5. Route the cable over or through the transom. 6. On the outside of the hull secure the cable against the transom using the included cable clamps. Evenly distribute the clamps between the transducer and the location where the cable passes through or over the hull and mark the location with a pencil (Figure 6). 7. At the marked locations, use a 1/8" (3 mm) bit to drill a hole 3/8 (10 mm) deep. To prevent drilling too deeply, wrap masking tape around the bit 3/8" 8. Apply marine sealant to the threads of the 2 #6 x 1/2" self-tapping screws, position the two cable clamps and fasten them in place. (skip to #13 if the cable was routed over the transom or a hole that was already in the hull) 9. If a hole has been drilled in the transom position the clam shell cover over the cable where it enters the hull and mark the two screw holes. 10. Use a 3 mm or 1/8" bit to drill a hole 10 mm (3/8") deep. To prevent drilling too deeply, wrap masking tape around the bit 10 mm (3/8") from the point of the bit. 11. Fill the remaining space in the hole with marine sealant. 12. Apply marine sealant to the 2 #6 x 1/2" self-tapping screws and fasten the cable clam shell cover into place. 13. Route the cable to the depth sounder to the mounting location of the depth sounder. To reduce electrical interference, separate the transducer cable from other electrical wiring. Coil any excess cable and secure it in place using tie-wraps. 14. Refer to the depth sounder owner s manual to connect the transducer to the instrument. Checking for Leaks WARNING!!!! When the boat is placed in the water, immediately check for leaks around the screws and any holes drilled in the hull. Never install a transducer and leave the boat in the water unchecked

7 Antifouling Paint Marine growth can accumulate rapidly on the transducer s surface. If the vessel is left in saltwater for extended periods of time, all components of the transducer below the waterline must be painted with WATER BASED antifouling paint. Never use ketone-based paint, as this type of paint can damage to the transducer s plastic shell. Clear, spray on antifouling paints are very easy to apply and can be purchased from your local boating supply store. Reapply paint as needed to prevent marine growth. Testing 1. Become familiar with the depth sounders function and performance at idle speeds. 2. Gradually increase the boat speed and observe performance of the depth sounder. 4. If the performance improves when turning, the sensors position probably needs adjustment because it is in aerated water. 5. Move the transducer farther down on the transom. 6.If the performance does not improve, move the transducer closer to the centerline making sure to fill any unused screw holes with marine sealant. High Speed performance of the depth sounder may require extensive adjustment and testing to find the best transducer mounting location. This transducer has been tested to perform up to 63 MPH in a transom mount application. Not all boat hull configuration will allow for this type of performance. If you are not satisfied with the performance of the depth sounder, it is recommended that you seek the advice of a professional marine electronics installer. IN-HULL MOUNTING THE TRANSDUCER Applications Please read the instructions completely before proceeding with the installation. High Speed Boats to increase the performance of the depth sounder. Trailer boats to prevent accidental damage to the transducer from trailering. Shallow draft boats to prevent accidental damage to the transducer to from intentional or unintentional ground. NON-CORED hulls or Aluminum Hulls thinner than 1/8 Hull Material Since the hull absorbs acoustic energy, transmitting through the hull reduces the transducers performance. Fiberglass hulls are often reinforced in places for added strength. These cored areas contain balsa wood or structural foam which are poor sound conductors. To achieve optimal performance, find a location where the hull laminate is solid (not cored). Figure 7 Location Consult the boat manufacturer for the best in-hull transducer placement. If this information is unavailable, follow the guidelines below and see Figure 7. Outboard powerboats - Install as close to the stern as possible Inboard / outboard powerboats - Install close to the engine(s) Inboard powerboats - Install forward of the propeller(s) and shaft(s) Sailboats - Install near the centerline of the hull and forward of the leading edge of the keel Outboard & Inboard/Outboard Inboard Sailboat Testing at the Selected Location Place the boat into a body of water where the depth is generally known (you may also consider using a stick to hang the transducer over the side of the vessel to develop known depth readings). Figure 8 While the boat is anchored, use one of the methods below in Figure 8 to test the depth sounder with the transducer at the desired in-hull location. If the test readings noticeably differ from the known depth you will need to find another location. If the readings are similar mark the spot in the hull and proceed to Selecting the Adhesive. A FIGURE 8A If the hull surface is not smooth, sand it with 30 grit sandpaper until a B C smooth surface is obtained. Partially fill a thin plastic bag with water, place the transducer inside and close it tightly with a tie wrap. Wet the surface of the hull and press the transducer face against it through the bag. FIGURE 8B If the transducer will be located in an area in the hull that holds water, place the transducer against the hull and allow bilge water to cover the surface where the transducer touches the hull. FIGURE 8C If the hull surface is not smooth, sand it with 30 grit sandpaper until a smooth surface is obtained. Coat the face of the transducer with petroleum jelly and press it against the hull with a twisting motion. Use duct tape to hold it in place If you do not get satisfactory depth readings, try different locations inside the hull. If you cannot obtain a satisfactory reading using these methods, you will not be able to mount the tranducer in-hull on your vessel. Please contact NMP at for transducer exchange information.

8 Selecting the Adhesive Use a viscous slow-cure epoxy or a fairly rigid, one part adhesive sealant. In cold climates, a one-part polyurethane adhesive, such as Boat-Life s Life Seal may be best. Do not use 5 minute epoxies because they are generally brittle. RTV (silicone) adhesives (Weather Sealants, Rubbery Caulks, 3M 5200, etc) are not recommended because most of the sound energy is lost. Gluing In Place 1. All surfaces to be bonded must be smooth, clean and dry. If the hull surface is not smooth, sand it with 30 grit sandpaper until a smooth surface is obtained in an area a little larger in diameter than the length of the transducer. 2. Clean and dry both the selected area and the face of the transducer with a weak solvent to remove any dust, grease or oil. 3. Prepare the adhesive as per the directions supplied with the adhesive. 4. Apply a generous amount of adhesive to the center of the face of the transducer (side opposite from the cable). WARNING!!!! DO NOT glue the transducer in place until the location is tested as per the Testing at the Selected Location section in this manual. 5. Press the transducer face onto the hull with a twisting motion to expel all air bubbles. (If the hull is slanted, temporarily secure the transducer in place with duct tape.) Allow the adhesive to cure as per the manufacturer s instructions. 6. After the adhesive has cured, route the cable to the depth sounder mounting location. To reduce electrical interference, separate the transducer cable from other electrical wiring and coil and secure the excess cable in place using tie-wraps. TROUBLESHOOTING GUIDE The Depth Reading on the Depth Sounder is Random, Flashing, and Inconsistent 1. Operate the unit under normal operating specifications and check to see if it operating properly (pay attention to minimum and maximum depth capabilities). 2. If this condition occurs only at certain speeds, then a transducer adjustment is needed. Refer to the Helpful Hints for Transducer Installation section below. Refer to the Transducer Adjustment Instructions for adjustment procedures. 3. Under certain circumstances sonar may not perform at the best of its ability. Extremely dirty water, very soft bottom, high speeds, deep water, or a combination of the above will result in incomplete or inaccurate readings. Please refer to the Transducer Adjustment Instructions to minimize the effects of these conditions. 4. If the transducer is transom mounted check to make sure that the transducer is not kicked-up. To prevent damage to the transducer, it will automatically release from mounting bracket (kick-up) when it is impacted. If this occurs refer to the Transducer Installation Instructions to reset the transducer for normal operation. If this happens frequently make sure that the trailer or boat lift bunks do not interfere with the transducer during loading and unloading. 5. Check the transducer cable connection on the back of the depth sounder. Make sure that the connection is made as per the instructions supplied with the depth sounder. 6. Contact NMP at for assistance if you are unable to correct the problems. Helpful Hints for Transducer Installation (Transom Mounting) 1. Make sure the transducer is not mounted in any area where the water flow is interrupted by propeller turbulence or aerated water. If standing at eye level, behind the transducer and looking forward along the bottom of the boat hull there should NOT be any strakes, chimes, steps, or hull fittings inline with the transducer. If there are any of these obstructions, the transducer will need to be relocated to achieve optimal performance. The transducer CAN NOT be transom mounted on a Stepped-Hull vessel, it must only be in-hull mounted. 2. Make sure that the leading edge (bow - side closest to the bow of the boat) of the transducer extends at least 1/8 (3 mm) below the bottom of the hull. Also make sure that the trailing edge (stern - side furthest from the bow of the boat) is 1/16 to 1/18 (1-3 mm) below the leading edge. Figure 9 slight angle Helpful Hints for Transducer Installation (In-Hull Mounting) 1. The hull must be made out of solid fiberglass or a maximum 1/8 (3 mm) aluminum. The unit will not work through wood, plastic, or any other composite material. 2. The glue in location must be in direct contact with the water at all times during operation. The transducer CAN NOT be mounted in any area where the water flow is interrupted by propeller turbulence or aerated water. It MUST NOT be mounted behind any strakes, chimes, steps, or hull fittings that will disrupt the flow of clean water to the transducer (in line with the mounting location of the transducer and the bow of the boat). If there are any of these obstructions, the transducer will need to be relocated to achieve optimal performance. 3. If mounting in-hull on a stepped hull vessel, the transducer must be mounted in a location where there are no steps forward of the transducer (between the transducer mounting location and the bow of the boat). Keep in mind that the glue in location must be in direct contact with the water at all times during operation or incorrect depth readings will occur. The Transducer Cable Supplied with the Transducer is Too Short for My Installation, Can It Be Extended YES: To extend the transducer cable: 1. Cut the cable on the transducer side 1 (28 mm) from the plug. If the depth sounder display also has a plug, you will need to cut this plug off as well. 2. At both cuts, strip back the rubber cable cover 1 (28 mm) exposing the three internal wires (blue, white, and bare). 3. Using a soldering iron, solder the desired length extension cable (available at a boating supply store or by calling ) between the depth sounder display and the transducer. Be certain that the blue, white and bare wires are connected properly between the depth sounder display and the transducer and make sure the colors are consistantly matched throughout the splice. 4. Using electrical tape, or heat shrink tubing make certain that the soldered connections are completely sealed and protected Specifications Sonar Beam Angle 20 Degrees against accidental electrical interference. Sonar Frequency 200 KHZ 6450 Kingspoint Parkway, Suite 6 Orlando, FL (p) Norcross Marine Products, Inc., All rights reserved. All specifications are subject to change without notice. Transducer Cable Length 25 Feet (7.6 M) WARNING: Disassembly of the electronic components within this unit may result in exposure to lead in the form of solder, which is known to the state of California to cause cancer, birth defects, and other reproductive harm.

9 Drill Mounting Holes Here CENTERLINE OF VESSEL (Keel, Drive) X X This Line Vertical STARBOARD SIDE OF VESSEL Align Arrow Tip w/ Bottom of Boat This Line Parallel To Vessel s Waterline

Model No. D10D INSTALLATION AND OPERATION MANUAL D10DX.01T Digital Depth Sounder with Air & Water Temperature, Transom Mount Transducer

Model No. D10D INSTALLATION AND OPERATION MANUAL D10DX.01T Digital Depth Sounder with Air & Water Temperature, Transom Mount Transducer SAFETY INFORMATION: To ensure safety and many years of trouble-free

Model No. D10D INSTALLATION AND OPERATION MANUAL D10DX.01T Digital Depth Sounder with Air & Water Temperature, Transom Mount Transducer SAFETY INFORMATION: To ensure safety and many years of trouble-free

Model No. D10D INSTALLATION AND OPERATION MANUAL D11S Surface Mount Digital Depth Sounder with Transom/Glue-In Transducer

Model No. D10D INSTALLATION AND OPERATION MANUAL D11S Surface Mount Digital Depth Sounder with Transom/Glue-In Transducer SAFETY INFORMATION: To ensure safety and many years of trouble-free operation of

Model No. D10D INSTALLATION AND OPERATION MANUAL D11S Surface Mount Digital Depth Sounder with Transom/Glue-In Transducer SAFETY INFORMATION: To ensure safety and many years of trouble-free operation of

Depth transducer TH 52

Depth transducer TH 52 performance by NEXUS NETWORK Installation Manual English DEPTH TH52 English 11-1 English DEPTH TH52 11-2 DEPTH TH52 English CONTENTS: 1 Applications...4 2 Tools and Materials Needed...4

Depth transducer TH 52 performance by NEXUS NETWORK Installation Manual English DEPTH TH52 English 11-1 English DEPTH TH52 11-2 DEPTH TH52 English CONTENTS: 1 Applications...4 2 Tools and Materials Needed...4

USER S GUIDE DepthTrax 1H HawkEye Portable Depth Finder (DT1H)

USER S GUIDE DepthTrax 1H HawkEye Portable Depth Finder (DT1H) Thank you for purchasing a HawkEye product, and welcome to the innovations of NorCross Marine Products, Inc. To ensure safety and many years

USER S GUIDE DepthTrax 1H HawkEye Portable Depth Finder (DT1H) Thank you for purchasing a HawkEye product, and welcome to the innovations of NorCross Marine Products, Inc. To ensure safety and many years

This document to be used with Hurley traditional Davits

~ InstructIon Manual ~ This document to be used with Hurley traditional Davits WarnIngs WarnIng - Failure to install, maintain, protect, and operate the system properly can cause malfunction resulting

~ InstructIon Manual ~ This document to be used with Hurley traditional Davits WarnIngs WarnIng - Failure to install, maintain, protect, and operate the system properly can cause malfunction resulting

TRANSDUCER RESOURCE GUIDE EN_A

TRANSDUCER RESOURCE GUIDE 532651-1EN_A THANK YOU! Thank you for choosing Humminbird, the #1 name in marine electronics. Humminbird has built its reputation by designing and manufacturing top quality, thoroughly

TRANSDUCER RESOURCE GUIDE 532651-1EN_A THANK YOU! Thank you for choosing Humminbird, the #1 name in marine electronics. Humminbird has built its reputation by designing and manufacturing top quality, thoroughly

Model PSI Compressor with 3-Gallon Air Tank 12VDC

Model 6350 150 PSI Compressor with 3-Gallon Air Tank 12VDC IMPORTANT: It is essential that you and any other operator of this product read and understandd the contents of this manual before installing

Model 6350 150 PSI Compressor with 3-Gallon Air Tank 12VDC IMPORTANT: It is essential that you and any other operator of this product read and understandd the contents of this manual before installing

Panoptix PS51-TH FrontVü/LiveVü Thruhull

Panoptix PS51-TH FrontVü/LiveVü Thruhull Transducer Installation Instructions Important Safety Information WARNING See the Important Safety and Product Information guide in the chartplotter or fishfinder

Panoptix PS51-TH FrontVü/LiveVü Thruhull Transducer Installation Instructions Important Safety Information WARNING See the Important Safety and Product Information guide in the chartplotter or fishfinder

PIRANHA I & 2 OPERATION GUIDE

PIRANHA I & 2 OPERATION GUIDE Thank You Thank you for purchasing a Piranha fishfinder from Humminbird, America s #1 Manufacturer of quality consumer marine electronics WARNING! This device should not be

PIRANHA I & 2 OPERATION GUIDE Thank You Thank you for purchasing a Piranha fishfinder from Humminbird, America s #1 Manufacturer of quality consumer marine electronics WARNING! This device should not be

INSTALLING THE ECHO SOUNDER TRANSDUCER CHANGING THE OPERATING CONFIGURATION

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE LOG PADDLE WHEEL UNIT INSTALLING THE ECHO SOUNDER TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE USING THE INSTRUMENT SETTING THE MINIMUM DEPTH ALARM SETTING

Installation and service should be performed by a qualified service professional.

Damage to your lift or vessel can result from improper initial setup of the system. Consult a HydroHoist Certified Installer for initial setup and support Installation and service should be performed by

Damage to your lift or vessel can result from improper initial setup of the system. Consult a HydroHoist Certified Installer for initial setup and support Installation and service should be performed by

HawkEye Handheld Sonar System PX Instruction Manual

HawkEye Handheld Sonar System PX Instruction Manual Part #: DF2200PX Before You Venture Outdoors: Get to know the fishing regulations and habits of the fish that you are targeting by visiting your local

HawkEye Handheld Sonar System PX Instruction Manual Part #: DF2200PX Before You Venture Outdoors: Get to know the fishing regulations and habits of the fish that you are targeting by visiting your local

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock: - Do not disassemble. Do not attempt repairs or modifications. Refer to qualified service agencies for all service and repairs.

IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock: - Do not disassemble. Do not attempt repairs or modifications. Refer to qualified service agencies for all service and repairs.

400C & 450C DUAL PERFORMANCE VALUE PACKS

(Chrome) PART NO. 40013 (Silver) PART NO. 45012 (Chrome) PART NO. 45013 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before

(Chrome) PART NO. 40013 (Silver) PART NO. 45012 (Chrome) PART NO. 45013 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before

444C DUAL PERFORMANCE VALUE PACK

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

(Chrome) PART NO. 44432 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS MANUAL

100C Air Compressor Kit

10010 100C Air Compressor (standard mounting bracket, CE Spec) 10014 100C Air Compressor (no leader hose or check valve, CE Spec) 10016 100C Air Compressor (with Omega Bracket, CE Spec) IMPORTANT: It is

10010 100C Air Compressor (standard mounting bracket, CE Spec) 10014 100C Air Compressor (no leader hose or check valve, CE Spec) 10016 100C Air Compressor (with Omega Bracket, CE Spec) IMPORTANT: It is

200 PSI COMPRESSORS - MODEL NUMBERS

200 PSI COMPRESSORS - MODEL NUMBERS 380C AIR COMPRESSOR KIT PART NO. 38033 480C AIR COMPRESSOR KIT PART NO. 48043 380C 480C IMPORTANT: It is essential that you and any other operator of this product read

200 PSI COMPRESSORS - MODEL NUMBERS 380C AIR COMPRESSOR KIT PART NO. 38033 480C AIR COMPRESSOR KIT PART NO. 48043 380C 480C IMPORTANT: It is essential that you and any other operator of this product read

420C AIR COMPRESSOR KIT PART NO C AIR COMPRESSOR KIT PART NO

420C AIR COMPRESSOR KIT PART NO. 42042 460C AIR COMPRESSOR KIT PART NO. 46043 420C 460C IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this

420C AIR COMPRESSOR KIT PART NO. 42042 460C AIR COMPRESSOR KIT PART NO. 46043 420C 460C IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this

Depth sensor. Product reference : REV 1. USER GUIDE and INSTALLATION GUIDE. nke Sailing competition

Depth sensor Product reference : 90-60-456 REV 1 USER GUIDE and INSTALLATION GUIDE nke Sailing competition Z.I. Kerandré Rue Gutenberg 56700 HENNEBONT- FRANCE http://www.nke.fr After sale service n 33

Depth sensor Product reference : 90-60-456 REV 1 USER GUIDE and INSTALLATION GUIDE nke Sailing competition Z.I. Kerandré Rue Gutenberg 56700 HENNEBONT- FRANCE http://www.nke.fr After sale service n 33

400H HARDMOUNT AIR COMPRESSOR KIT PART NO H HARDMOUNT AIR COMPRESSOR KIT PART NO

400H HARDMOUNT AIR COMPRESSOR KIT PART NO. 40042 450H HARDMOUNT AIR COMPRESSOR KIT PART NO. 45042 400H 450H IMPORTANT: It is essential that you and any other operator of this product read and understand

400H HARDMOUNT AIR COMPRESSOR KIT PART NO. 40042 450H HARDMOUNT AIR COMPRESSOR KIT PART NO. 45042 400H 450H IMPORTANT: It is essential that you and any other operator of this product read and understand

250C-IG COMPRESSOR KIT 12V PART NO C-IG COMPRESSOR KIT 24V PART NO

250C-IG COMPRESSOR KIT 12V PART NO. 25050 250C-IG COMPRESSOR KIT 24V PART NO. 25058 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual

250C-IG COMPRESSOR KIT 12V PART NO. 25050 250C-IG COMPRESSOR KIT 24V PART NO. 25058 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual

250C-IG COMPRESSOR KIT 12V PART NO C-IG COMPRESSOR KIT 24V PART NO

250C-IG COMPRESSOR KIT 12V PART NO. 25050 250C-IG COMPRESSOR KIT 24V PART NO. 25058 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual

250C-IG COMPRESSOR KIT 12V PART NO. 25050 250C-IG COMPRESSOR KIT 24V PART NO. 25058 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual

Installation, Compensation and Maintenance Instructions for. RITCHIE Compasses. Made In U.S.A

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

Installation, Compensation and Maintenance Instructions for RITCHIE Compasses Made In U.S.A All Magnetic Compasses are vulnerable to magnetic interference, which will produce errors, called deviation.

INSTALLATION PREPARATION

PARTS SUPPLIED INSTALLATION PREPARATION PARTS SUPPLIED Before installing your new Humminbird fishfinder, please ensure the following parts are included in the box: Fishfinder Transducer with 20 (6m) of

PARTS SUPPLIED INSTALLATION PREPARATION PARTS SUPPLIED Before installing your new Humminbird fishfinder, please ensure the following parts are included in the box: Fishfinder Transducer with 20 (6m) of

INSTALLATION INSTRUCTIONS AT-SERIES ANCHOR ASSEMBLY PART NUMBER: F-04CAJP 450 LB. [204kg] MAXIMUM CAPACITY (PRO POOL LIFT)

![INSTALLATION INSTRUCTIONS AT-SERIES ANCHOR ASSEMBLY PART NUMBER: F-04CAJP 450 LB. [204kg] MAXIMUM CAPACITY (PRO POOL LIFT) INSTALLATION INSTRUCTIONS AT-SERIES ANCHOR ASSEMBLY PART NUMBER: F-04CAJP 450 LB. [204kg] MAXIMUM CAPACITY (PRO POOL LIFT)](/thumbs/90/102183460.jpg) INSTALLATION INSTRUCTIONS AT-SERIES ANCHOR ASSEMBLY PART NUMBER: F-04CAJP 450 LB. [204kg] MAXIMUM CAPACITY (PRO POOL LIFT) - WARNING- IMPORTANT SAFETY INSTRUCTIONS 1. READ AND FOLLOW ALL INSTRUCTIONS.

INSTALLATION INSTRUCTIONS AT-SERIES ANCHOR ASSEMBLY PART NUMBER: F-04CAJP 450 LB. [204kg] MAXIMUM CAPACITY (PRO POOL LIFT) - WARNING- IMPORTANT SAFETY INSTRUCTIONS 1. READ AND FOLLOW ALL INSTRUCTIONS.

USER S GUIDE H22FX HawkEye Handheld Sonar System with Integrated LED Flashlight

USER S GUIDE H22FX HawkEye Handheld Sonar System with Integrated LED Flashlight Thank you for purchasing a HawkEye product, and welcome to the innovations of NorCross Marine Products, Inc. To ensure safety

USER S GUIDE H22FX HawkEye Handheld Sonar System with Integrated LED Flashlight Thank you for purchasing a HawkEye product, and welcome to the innovations of NorCross Marine Products, Inc. To ensure safety

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission

Copyright 2004 by the Thomas G. Faria Corporation, Uncasville CT No part of this publication may by reproduced in any form, in an electronic retrieval system or otherwise, without the prior written permission

SEADUCER BOATS GAS MONO COME VISIT US ON THE WEB AT

SEADUCER BOATS GAS MONO COME VISIT US ON THE WEB AT WWW.SEADUCERBOATS.COM 1 - Pkg. Of 440 push rod ends 1 - Pkg. of solder-on rod ends 2 -water outlet fitting 1-1/4" prop nut 1 -.250" x 24" flex shaft

SEADUCER BOATS GAS MONO COME VISIT US ON THE WEB AT WWW.SEADUCERBOATS.COM 1 - Pkg. Of 440 push rod ends 1 - Pkg. of solder-on rod ends 2 -water outlet fitting 1-1/4" prop nut 1 -.250" x 24" flex shaft

450P- RV AUTOMATIC PORTABLE COMPRESSOR EXTREME SERIES

450P- RV AUTOMATIC PORTABLE COMPRESSOR EXTREME SERIES PART NO. 45053 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing

450P- RV AUTOMATIC PORTABLE COMPRESSOR EXTREME SERIES PART NO. 45053 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing

What hull material types will the system work on? Do I still need an antifoul paint?

1. The Hull What hull material types will the system work on? The system is effective on all GRP (Glass Reinforced Plastic), STEEL and ALUMINIUM hulls up to thickness of 70mm. Unfortunately the system

1. The Hull What hull material types will the system work on? The system is effective on all GRP (Glass Reinforced Plastic), STEEL and ALUMINIUM hulls up to thickness of 70mm. Unfortunately the system

PLAQUE MFM0680 UNDERWATER LIGHT. Operating Instructions

PLAQUE MFM0680 UNDERWATER LIGHT Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light PLAQUE MFM0680... 4 Power Supply Unit MPS021000

PLAQUE MFM0680 UNDERWATER LIGHT Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light PLAQUE MFM0680... 4 Power Supply Unit MPS021000

450P AUTOMATIC PORTABLE COMPRESSOR EXTREME SERIES

EXTREME SERIES PART NO. 45043 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS

EXTREME SERIES PART NO. 45043 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using this product. SAVE THIS

DS400 & DS500 Digital Fishfinders

DS400 & DS500 Digital Fishfinders Owner s Handbook Document number: 81234-1 Date: December 2003 DS400 and DS500 Digital Fishfinders iii Preface This handbook describes the Raymarine DS400 and DS500 Digital

DS400 & DS500 Digital Fishfinders Owner s Handbook Document number: 81234-1 Date: December 2003 DS400 and DS500 Digital Fishfinders iii Preface This handbook describes the Raymarine DS400 and DS500 Digital

INSTALLING YOUR CLC RUDDER

INSTALLING YOUR CLC RUDDER These instructions are written to help you install the CLC rudder kit on your wooden kayak. The rudder can be fitted to your boat during construction or after completion. Please

INSTALLING YOUR CLC RUDDER These instructions are written to help you install the CLC rudder kit on your wooden kayak. The rudder can be fitted to your boat during construction or after completion. Please

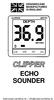

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH METRES ECHO SOUNDER.

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

INSTALLATION.. 6 Transom Installation... 6 Inside the Hull Installation. 10 Control Head Installation Test the Installation 15

TABLE OF CONTENTS INSTALLATION PREPARATION 2 Parts Supplied. 2 Accessories. 2 Installation Overview.. 2 Alternative Transducers and Mounting Methods... 4 Transducer Exchange 5 INSTALLATION.. 6 Transom

TABLE OF CONTENTS INSTALLATION PREPARATION 2 Parts Supplied. 2 Accessories. 2 Installation Overview.. 2 Alternative Transducers and Mounting Methods... 4 Transducer Exchange 5 INSTALLATION.. 6 Transom

MODEL 9875 STADIUM BASEBALL SCOREBOARD. Instruction Manual

UNITEC MANUFACTURING DIVISION MODEL 9875 STADIUM BASEBALL SCOREBOARD (WITH INNING BY INNING SCORING) Instruction Manual Mailing Address: PO Box 260, Yorkville, NY 13495-0260 Plant Address: 34 Main Street,

UNITEC MANUFACTURING DIVISION MODEL 9875 STADIUM BASEBALL SCOREBOARD (WITH INNING BY INNING SCORING) Instruction Manual Mailing Address: PO Box 260, Yorkville, NY 13495-0260 Plant Address: 34 Main Street,

User s Manual. USB Golf Simulator. Contents

USB Golf Simulator User s Manual Contents safety information...1 identifying the components...2 assembly in 3 easy steps...3 plug & play...4 playing tips...5 care...6 troubleshooting...7 notes...8 warranty...9

USB Golf Simulator User s Manual Contents safety information...1 identifying the components...2 assembly in 3 easy steps...3 plug & play...4 playing tips...5 care...6 troubleshooting...7 notes...8 warranty...9

OWNER'S MANUAL FISHING AND PONTOON BOAT ANCHOR WINCH. 24' Class Rope Anchor Winch

OWNER'S MANUAL 24' Class Rope Anchor Winch FISHING AND PONTOON BOAT ANCHOR WINCH PW24101 The 24 Class anchor winch is a 12VDC power winch that retrieves and deploys river, mushroom, or navy type anchors

OWNER'S MANUAL 24' Class Rope Anchor Winch FISHING AND PONTOON BOAT ANCHOR WINCH PW24101 The 24 Class anchor winch is a 12VDC power winch that retrieves and deploys river, mushroom, or navy type anchors

97C COMPRESSOR KIT 12V PART NO C COMPRESSOR KIT 24V PART NO C COMPRESSOR KIT PART NO

97C COMPRESSOR KIT 12V PART NO. 00097 97C COMPRESSOR KIT 24V PART NO. 02497 98C COMPRESSOR KIT PART NO. 00098 97C 98C IMPORTANT: It is essential that you and any other operator of this product read and

97C COMPRESSOR KIT 12V PART NO. 00097 97C COMPRESSOR KIT 24V PART NO. 02497 98C COMPRESSOR KIT PART NO. 00098 97C 98C IMPORTANT: It is essential that you and any other operator of this product read and

M3-LED. Operator s Manual. Operator s Manual MADE IN THE USA USA

M3-LED Operator s Manual Operator s Manual MADE IN THE USA USA Section TABLE OF CONTENTS Page Warnings and Cautions... 1 M3-LED Parts Diagram... 4 Mounting... 6 Dismounting... 8 Switch Operation... 10

M3-LED Operator s Manual Operator s Manual MADE IN THE USA USA Section TABLE OF CONTENTS Page Warnings and Cautions... 1 M3-LED Parts Diagram... 4 Mounting... 6 Dismounting... 8 Switch Operation... 10

Thank you for purchasing your new Empire Reloader B Sound-Activated 3-Speed Paintball Hopper!

Thank you for purchasing your new Empire Reloader B Sound-Activated 3-Speed Paintball Hopper! Should you require any technical assistance on the use of this product, or if your product needs servicing,

Thank you for purchasing your new Empire Reloader B Sound-Activated 3-Speed Paintball Hopper! Should you require any technical assistance on the use of this product, or if your product needs servicing,

OWNER'S MANUAL FREE FALL ROPE AND CHAIN ANCHOR WINCH. 12 Volt Powered Winch Power-In / Freewheel-out operation. 36', 41' and 46' Class Anchor Winch

OWNER'S MANUAL 36', 41' and 46' Class Anchor Winch FREE FALL ROPE AND CHAIN ANCHOR WINCH PW46101 12 Volt Powered Winch Power-In / Freewheel-out operation These instructions apply to all models listed.

OWNER'S MANUAL 36', 41' and 46' Class Anchor Winch FREE FALL ROPE AND CHAIN ANCHOR WINCH PW46101 12 Volt Powered Winch Power-In / Freewheel-out operation These instructions apply to all models listed.

CLIPPER DEPTH METRES ENTER SHALL DEEP ILLUM CLIPPER ECHO SOUNDER

CLIPPER DEPTH DEPTH DUET CLIPPER ECHO SOUNDER INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE GETTING STARTED OPERATIONAL CONTROLS BACKLIGHT SETTING CHANGING

CLIPPER DEPTH DEPTH DUET CLIPPER ECHO SOUNDER INTRODUCTION INSTALLING THE DISPLAY INSTALLING THE TRANSDUCER NOTES ON ELECTRICAL INTERFERENCE GETTING STARTED OPERATIONAL CONTROLS BACKLIGHT SETTING CHANGING

Soling Building Tips II

Soling Building Tips II Prepared: Arthur Deane Jan 20, 2002 adeane@ic.net Introduction The following are some lessons learned and experience gained in building a Soling kit. The plan developed is based

Soling Building Tips II Prepared: Arthur Deane Jan 20, 2002 adeane@ic.net Introduction The following are some lessons learned and experience gained in building a Soling kit. The plan developed is based

SEADUCER BOATS GAS SPORT HYDRO

SEADUCER BOATS GAS SPORT HYDRO COME VISIT US ON THE WEB AT WWW.SEADUCERBOATS.COM 2 - Pkg. Of 440 push rod ends 2 - Pkg. of solder-on rod ends 2 -water outlet fitting 1-1/4" prop nut 1 -.250" x 30" flex

SEADUCER BOATS GAS SPORT HYDRO COME VISIT US ON THE WEB AT WWW.SEADUCERBOATS.COM 2 - Pkg. Of 440 push rod ends 2 - Pkg. of solder-on rod ends 2 -water outlet fitting 1-1/4" prop nut 1 -.250" x 30" flex

ROPV R40 E Series User Manual

HARBIN ROPV INDUSTRY DEVELOPMENT CENTER ROPV R40 E Series User Manual For Use with the Following ROPV Pressure Vessel Models: R40 300E R40 450E Headquarters Tel:(+86)451-82267301 Fax:(+86)451-82267303

HARBIN ROPV INDUSTRY DEVELOPMENT CENTER ROPV R40 E Series User Manual For Use with the Following ROPV Pressure Vessel Models: R40 300E R40 450E Headquarters Tel:(+86)451-82267301 Fax:(+86)451-82267303

MODEL NUMBER: M20005 AIR SOURCE KIT. 30% Duty Compressor on. 2.0 Gallon Air Tank SAVE THIS MANUAL FOR FUTURE REFERENCE

MODEL NUMBER: M20005 AIR SOURCE KIT 30% Duty Compressor on 2.0 Gallon Air Tank SAVE THIS MANUAL FOR FUTURE REFERENCE USER MANUAL IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock

MODEL NUMBER: M20005 AIR SOURCE KIT 30% Duty Compressor on 2.0 Gallon Air Tank SAVE THIS MANUAL FOR FUTURE REFERENCE USER MANUAL IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock

SASK-A-POLE OWNERS AND USERS MANUAL

SASK-A-POLE OWNERS AND USERS MANUAL GENERAL INFORMATION The Saskatchewan Abilities Council s Sask-a-Pole accessibility and transfer aid is designed to help provide safe and easy access to chairs, beds,

SASK-A-POLE OWNERS AND USERS MANUAL GENERAL INFORMATION The Saskatchewan Abilities Council s Sask-a-Pole accessibility and transfer aid is designed to help provide safe and easy access to chairs, beds,

SECTION 10iS: TAILCONE

VAN'S AIRCRAFT, INC. F-1282-R BOTTOM RIGHT SKIN F-1283C J-STIFFENER F-1278 TOP SKIN F-00009-L ADAHRS BRACKET F-00009-R ADAHRS BRACKET F-1279-R UPPER RIGHT SKIN F-1280-R RIGHT SIDE SKIN SECTION 10iS: TAILCONE

VAN'S AIRCRAFT, INC. F-1282-R BOTTOM RIGHT SKIN F-1283C J-STIFFENER F-1278 TOP SKIN F-00009-L ADAHRS BRACKET F-00009-R ADAHRS BRACKET F-1279-R UPPER RIGHT SKIN F-1280-R RIGHT SIDE SKIN SECTION 10iS: TAILCONE

D10D - Digital Depth Sounder

D10D - Digital Depth Sounder With auto-ranging and auto-sensitivity features the D10D is designed to give precise depth readings from 2.5 to 200 feet at speeds up to 63 mph. Algorithmic programming virtually

D10D - Digital Depth Sounder With auto-ranging and auto-sensitivity features the D10D is designed to give precise depth readings from 2.5 to 200 feet at speeds up to 63 mph. Algorithmic programming virtually

ULTRA-LIGHT DUTY ONBOARD AIR SYSTEM

ULTRA-LIGHT DUTY ONBOARD AIR SYSTEM PART NO. 10000 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using

ULTRA-LIGHT DUTY ONBOARD AIR SYSTEM PART NO. 10000 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of this manual before installing and using

MODEL NUMBER: P-A AUTOMATIC PORTABLE COMPRESSOR

MODEL NUMBER: 45043-450P-A AUTOMATIC PORTABLE COMPRESSOR IMPORTANT: It is essential that you and any other operator of the product read and understand the contents of this manual before installing and

MODEL NUMBER: 45043-450P-A AUTOMATIC PORTABLE COMPRESSOR IMPORTANT: It is essential that you and any other operator of the product read and understand the contents of this manual before installing and

Fiber Optic Lighted Bubbler Spillway Pot (DLP-45) Installation Manual

Fiber Optic Lighted Bubbler Spillway Pot (DLP-45) Installation Manual 27.75 23.75 25.50 20.75 Specifications: 8-13 GPM 100 strand fiber - Bubbler 75 strand fiber - Spillway Light Bar 45 ft. fiber tail

Fiber Optic Lighted Bubbler Spillway Pot (DLP-45) Installation Manual 27.75 23.75 25.50 20.75 Specifications: 8-13 GPM 100 strand fiber - Bubbler 75 strand fiber - Spillway Light Bar 45 ft. fiber tail

MODEL NUMBER: P PORTABLE COMPRESSOR

MODEL NUMBER: 44043-440P PORTABLE COMPRESSOR IMPORTANT: It is essential that you and any other operator of the product read and understand the contents of this manual before installing and using this product.

MODEL NUMBER: 44043-440P PORTABLE COMPRESSOR IMPORTANT: It is essential that you and any other operator of the product read and understand the contents of this manual before installing and using this product.

INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 SELECTING THE DISPLAY MODE 5 ABBREVIATIONS AND DEFINITIONS 17

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

CONTENTS CONTENTS 1 INSTALLATION 14 GENERAL INTRODUCTION TO B&G NETWORK 2 SITING THE UNIT 14 INTRODUCTION TO NETWORK WIND 3 MOUNTING THE UNIT 14 EXAMPLE SYSTEMS USING NETWORK WIND 4 SPECIFICATION 16 SELECTING

MODEL DIGITAL ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.5 TO 100FT (0.15 TO 30M) OPERATING RANGE SERIAL OUTPUT

MODEL 863-000-200 DIGITAL ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.5 TO 100FT (0.15 TO 30M) OPERATING RANGE SERIAL OUTPUT DOCUMENT NO. 430-017C April 14, 2005 S/N IMAGENEX TECHNOLOGY CORP. 209-1875

MODEL 863-000-200 DIGITAL ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.5 TO 100FT (0.15 TO 30M) OPERATING RANGE SERIAL OUTPUT DOCUMENT NO. 430-017C April 14, 2005 S/N IMAGENEX TECHNOLOGY CORP. 209-1875

MODEL ANALOG ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.2 TO 100FT OPERATING RANGE ANALOG OUTPUT

MODEL 862-000-200 ANALOG ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.2 TO 100FT OPERATING RANGE ANALOG OUTPUT DOCUMENT NO. 430-007H September 20, 2005 S/N IMAGENEX TECHNOLOGY CORP. 209-1875 BROADWAY

MODEL 862-000-200 ANALOG ALTIMETER USER'S MANUAL 330KHZ, 1000M DEPTH RATED 0.2 TO 100FT OPERATING RANGE ANALOG OUTPUT DOCUMENT NO. 430-007H September 20, 2005 S/N IMAGENEX TECHNOLOGY CORP. 209-1875 BROADWAY

200 PSI HIGH-FLOW AIR SOURCE KIT

200 PSI HIGH-FLOW AIR SOURCE KIT 50% Duty Compressor on 2.0 Gallon Air Tank PART NO. 20008 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of

200 PSI HIGH-FLOW AIR SOURCE KIT 50% Duty Compressor on 2.0 Gallon Air Tank PART NO. 20008 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of

42045 Heavy Duty ADA Base Model Kit: 85/105 PSI (ADA Compressor Only) Heavy Duty ADA Base Model Kit: 110/145 PSI (ADA Compressor Only)

42045 Heavy Duty ADA Base Model Kit: 85/105 PSI (ADA Compressor Only) 42047 Heavy Duty ADA Base Model Kit: 110/145 PSI (ADA Compressor Only) 45052 Constant Duty ADA Base Model Kit: 85/105 PSI (ADA Compressor

42045 Heavy Duty ADA Base Model Kit: 85/105 PSI (ADA Compressor Only) 42047 Heavy Duty ADA Base Model Kit: 110/145 PSI (ADA Compressor Only) 45052 Constant Duty ADA Base Model Kit: 85/105 PSI (ADA Compressor

INSTALLATION AND USER INSTRUCTIONS for TARGET 2 LOG, DEPTH & WIND MARINE INSTRUMENTS

INSTALLATION AND USER INSTRUCTIONS for TARGET 2 LOG, DEPTH & WIND MARINE INSTRUMENTS NASA MARINE LTD BOULTON ROAD STEVENAGE HERTS. SG1 4QG (01438) 354033 1: INTRODUCTION Target instruments are designed

INSTALLATION AND USER INSTRUCTIONS for TARGET 2 LOG, DEPTH & WIND MARINE INSTRUMENTS NASA MARINE LTD BOULTON ROAD STEVENAGE HERTS. SG1 4QG (01438) 354033 1: INTRODUCTION Target instruments are designed

MODEL NUMBER: PSI AIR SOURCE KIT 200 PSI Compressor on 2.0 Gallon 200 PSI Air Tank

IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock or Electrocution: MODEL NUMBER: 20008 200 PSI AIR SOURCE KIT 200 PSI Compressor on 2.0 Gallon 200 PSI Air Tank IMPORTANT: It is

IMPORTANT SAFETY INSTRUCTIONS CAUTION - To reduce risk of electrical shock or Electrocution: MODEL NUMBER: 20008 200 PSI AIR SOURCE KIT 200 PSI Compressor on 2.0 Gallon 200 PSI Air Tank IMPORTANT: It is

FILTERING ELECTRICAL INTERFERENCE

FILTERING ELECTRICAL INTERFERENCE Explanation The potential exists for interference to occur with some sonars due to a trolling motor's pulse width modulation speed control. With LCD models the display

FILTERING ELECTRICAL INTERFERENCE Explanation The potential exists for interference to occur with some sonars due to a trolling motor's pulse width modulation speed control. With LCD models the display

QUALITY ALUMINUM BOAT LIFTS, INC. INSTRUCTIONS. Dominator Lake Lift

INSTRUCTIONS Dominator Lake Lift PHONE:251-986-3882 * FAX:251-986-3136 QABLDOMINATORINST.2014 P a g e 1 Quality Aluminum Boat Lifts, INC. Installation Instructions: Dominator Lake Lift Thank you for your

INSTRUCTIONS Dominator Lake Lift PHONE:251-986-3882 * FAX:251-986-3136 QABLDOMINATORINST.2014 P a g e 1 Quality Aluminum Boat Lifts, INC. Installation Instructions: Dominator Lake Lift Thank you for your

PRODUCT SUPPORT MANUAL YACHT BEAM 6M Searchlight Remote Control System with Joystick Remote Control Panel

PRODUCT SUPPORT MANUAL YACHT BEAM 6M Searchlight Remote Control System with Joystick Remote Control Panel The Yacht Group - 4545 Ponce de Leon Blvd. Coral Gables FL 33146 Tel. 305.667.5811 - Fax. 305.663.5551

PRODUCT SUPPORT MANUAL YACHT BEAM 6M Searchlight Remote Control System with Joystick Remote Control Panel The Yacht Group - 4545 Ponce de Leon Blvd. Coral Gables FL 33146 Tel. 305.667.5811 - Fax. 305.663.5551

SR MARINER DIGITAL DEPTH METER DDM- 1 DDM- 2 INSTALLATION INSTRUCTIONS

SR MARINER DIGITAL DEPTH METER DDM- 1 DDM- 2 INSTALLATION INSTRUCTIONS Congratulatio n s in choosing a high perfor m a n c e marine instru m e n t and welcome to the growing family of SR Mariner produc

SR MARINER DIGITAL DEPTH METER DDM- 1 DDM- 2 INSTALLATION INSTRUCTIONS Congratulatio n s in choosing a high perfor m a n c e marine instru m e n t and welcome to the growing family of SR Mariner produc

275 RID Assembly Instructions

75 RID Assembly Instructions Part No. 0003003 v. Lscsep0 PARTS LIST (Specifications and contents subject to change without notice) Description Part # A. RID Track...0000050 B. Capacity Plate...0053 C.

75 RID Assembly Instructions Part No. 0003003 v. Lscsep0 PARTS LIST (Specifications and contents subject to change without notice) Description Part # A. RID Track...0000050 B. Capacity Plate...0053 C.

PLAQUE MFM18240 UNDERWATER LIGHT. Operating Instructions

PLAQUE MFM18240 UNDERWATER LIGHT Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light PLAQUE MFM18240... 4 Power Supply Unit MPS061000

PLAQUE MFM18240 UNDERWATER LIGHT Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light PLAQUE MFM18240... 4 Power Supply Unit MPS061000

RAM 4021-PR. Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021-PR Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-PR For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4

RAM 4021-PR Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021-PR For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4

Step 1: Block sand the transom to remove the seam joint. The end result should be a flat transom without a ledge where the seam joint is.

WhiplashGV Instruction Manual Email: Brian@Blazermarine.com Phone: 513-598-1769 Step 1: Block sand the transom to remove the seam joint. The end result should be a flat transom without a ledge where the

WhiplashGV Instruction Manual Email: Brian@Blazermarine.com Phone: 513-598-1769 Step 1: Block sand the transom to remove the seam joint. The end result should be a flat transom without a ledge where the

INSTRUCTION MANUAL. January 23, 2003, Revision 0

INSTRUCTION MANUAL Model 810A In-Vitro Test Apparatus for 310B Muscle Lever January 23, 2003, Revision 0 Copyright 2003 Aurora Scientific Inc. Aurora Scientific Inc. 360 Industrial Parkway S., Unit 4 Aurora,

INSTRUCTION MANUAL Model 810A In-Vitro Test Apparatus for 310B Muscle Lever January 23, 2003, Revision 0 Copyright 2003 Aurora Scientific Inc. Aurora Scientific Inc. 360 Industrial Parkway S., Unit 4 Aurora,

RAM Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

PRISMA. Installation, Operation, & Maintenance Manual. Climbing Panel + FREEMount System. NOTE TO INSTALLERS Always Read Instructions Before Use

PRISMA Climbing Panel + FREEMount System Installation, Operation, & Maintenance Manual NOTE TO INSTALLERS Always Read Instructions Before Use This Manual contains information on the proper installation

PRISMA Climbing Panel + FREEMount System Installation, Operation, & Maintenance Manual NOTE TO INSTALLERS Always Read Instructions Before Use This Manual contains information on the proper installation

Sideshift SS230 Installation on a 2006 Bayliner 265SB

The Sideshift SS230 was packaged very well and all parts were clearly labelled and documented. The overall quality seems far more durable than I expected... I was somewhat concerned that the unit may become

The Sideshift SS230 was packaged very well and all parts were clearly labelled and documented. The overall quality seems far more durable than I expected... I was somewhat concerned that the unit may become

WIND CLIPPER KTS ILLUM SCALE INC DEC CLIPPER WIND SYSTEM

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

Marine 6-Boat Free-Standing Racks SKU: Updated November 2011

Marine 6-Boat Free-Standing Racks SKU: 30-061 Updated November 011 Contains: Marine -Boat Free-Standing Racks (SKU 1-003) Marine 3 rd Boat Expansion Racks (SKU 1-0303) Marine Back Legs (SKU -001) 3 Sets

Marine 6-Boat Free-Standing Racks SKU: 30-061 Updated November 011 Contains: Marine -Boat Free-Standing Racks (SKU 1-003) Marine 3 rd Boat Expansion Racks (SKU 1-0303) Marine Back Legs (SKU -001) 3 Sets

200 PSI FAST-FILL AIR SOURCE KIT

200 PSI FAST-FILL AIR SOURCE KIT 55% Duty Compressor on 2.0 Gallon Air Tank PART NO. 20007 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of

200 PSI FAST-FILL AIR SOURCE KIT 55% Duty Compressor on 2.0 Gallon Air Tank PART NO. 20007 IMPORTANT: It is essential that you and any other operator of this product read and understand the contents of

RAM Operation Manual. Worldwide Manufacturer of Gas Detection Solutions

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

RAM 4021 Operation Manual Worldwide Manufacturer of Gas Detection Solutions TABLE OF CONTENTS RAM 4021 For Your Safety... 2 Description.... 2 Setup Mode.... 2 Lights/Alarms.... 3 Operation.... 4 Calibration....

Manual Leveling Control Installation/Operation

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

ELECTROMECHANICAL TRIM TAB SYSTEMS Manual Leveling Control Installation/Operation Linear Devices Corporation dba Lectrotab 11126 Air Park Road, Suite G Ashland, VA 23005 www.lectrotab.com Phone: 804-368-8428

Troyer s Gourd Rack 8 unit F R H O P

B E A D I M-N L Vertical Parts F R H O P Horizontal Parts C G J Updated 11/16 Parts List A: Top of Pole B: Bottom of Pole C: 48 Ground Stake D: Top Perch rods 48 long E: Hub F: Rope Winder w/ attached

B E A D I M-N L Vertical Parts F R H O P Horizontal Parts C G J Updated 11/16 Parts List A: Top of Pole B: Bottom of Pole C: 48 Ground Stake D: Top Perch rods 48 long E: Hub F: Rope Winder w/ attached

Model 6812C Dual Lane Scoreboard Owner s Manual

The Leader in Event Critical Timing Electronics Model 6812C Dual Lane Scoreboard Owner s Manual Portatree Eliminator Compatible Rev A RaceAmerica, Inc. P.O. Box 3469 Santa Clara, CA 95055-3469 (408) 988-6188

The Leader in Event Critical Timing Electronics Model 6812C Dual Lane Scoreboard Owner s Manual Portatree Eliminator Compatible Rev A RaceAmerica, Inc. P.O. Box 3469 Santa Clara, CA 95055-3469 (408) 988-6188

Owner s Manual. Model H4685

Owner s Manual Model H4685 TABLE OF CONTENTS Important Information.................................... 3 Parts.................................................. 4 Battery Installation......................................

Owner s Manual Model H4685 TABLE OF CONTENTS Important Information.................................... 3 Parts.................................................. 4 Battery Installation......................................

CONUS MSR0680 UNDERWATER LIGHT. Registered Community Design. Operating Instructions

CONUS MSR0680 UNDERWATER LIGHT Registered Community Design Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light CONUS MSR0680... 4 Power

CONUS MSR0680 UNDERWATER LIGHT Registered Community Design Operating Instructions CONTENTS Preface... 3 Features... 3 Precautions... 3 Controls and Connectors... 4 Underwater Light CONUS MSR0680... 4 Power

TABLE OF CONTENTS FRAME FEATURES INTRODUCTION

S3 DISC MANUAL TABLE OF CONTENTS Introduction...1 Frame Features...2 Fork Preparation...3 Small Parts...5 Frame Preparation...6 Brake Housing Installation...7 Mechanical Cable Routing...9 Electric Cable

S3 DISC MANUAL TABLE OF CONTENTS Introduction...1 Frame Features...2 Fork Preparation...3 Small Parts...5 Frame Preparation...6 Brake Housing Installation...7 Mechanical Cable Routing...9 Electric Cable