Achieving Reliable and Accurate Solids Level Measurement

|

|

|

- Peter Arnold

- 5 years ago

- Views:

Transcription

1 Achieving Reliable and Accurate Solids Level Measurement A white paper from Hycontrol

2 Achieving Reliable and Accurate Solids Level Measurement UK-based Hycontrol have been leaders in the field of level measurement and control for over thirty years, with a client portfolio stretching the full breadth of modern industry. Their equipment has been trusted to measure every conceivable product from corn flakes to nuclear waste. Here, the company explains the many different level measurement technologies currently available to users and the relative merits of each type. The accurate and reliable contents measurement of silos, vessels, hoppers and bins plays a vital role across a broad spectrum of industry sectors. There are a diverse range of fiscal and operational reasons for measuring contents including: Stock management and control Process control and optimisation Bulk out-loading Providing data for suppliers as part of a VMI (Vendor Managed Inventory) system Prevention of overfilling or over-pressurisation as part of an integrated safety system Improved Health & Safety compliance However, obtaining accurate and meaningful contents information is often not straightforward. Firstly, a high percentage of vessels are either not initially installed with pre-designed fit-for-purpose measuring systems or have outdated instrumentation that may already be redundant. Secondly, a complex blend of product characteristics, environmental conditions, operational parameters and budgetary constraints further complicate the situation. This means that when users need to obtain reliable data from their vessels they need to be able to make an informed decision on the best measurement solution for their particular application. The most common choices to provide this data are level measurement meters or

3 probes, retrofit strain sensors and strain gauge load cells. Each method has its advantages and disadvantages and, before choosing what is deemed to be the optimum solution, the user is faced with something of a dilemma. Consideration needs to be given to fundamental factors such as why are they measuring the contents? and what do they expect or want to achieve from the results? This might sound simple, but in many applications compromises need to be made based on a number of important commercial and engineering factors. It may be stating the obvious but level measurement and weight measurement are two very different things, and this may not be fully appreciated by the user. Although weight data can be obtained from level information the reliability of the conversion is dependent on a wide range of parameters. It is important to understand from the beginning that no sensor mounted on top of a silo actually measures level; it measures distance. It doesn t matter what technology is being used the primary measurement is the distance between the transmitter and the material being measured. Modern top-mounted level Engineers installing display panels for level monitoring equipment measurement systems are quite capable of measuring a distance to within just a few millimetres, and any accuracy quoted by the instrument manufacturer is based on this distance measurement. Level is discerned by programming the distance to the bottom of the vessel into the instrument. The instrument then automatically subtracts the distance measurement from the bottom value to determine a level. For example: if the distance between the transmitter and the tank bottom is entered as 8.5 metres and the instrument itself measures a distance of 2.5 metres to the surface of the material then the material level must be 6.0 metres (empty distance minus measured distance). This basic principle is the same across all of the available technologies that use a top-down measurement, and when used to measure liquids the accuracy quoted for the instrument will in most cases be correct. However, when considering the measurement of solids a number of other factors that affect accuracy come into play. This white paper sets out to explain what they are and what effect they have. In almost all applications initial purchase cost is the main driving factor in the decision process. Unfortunately this can impact negatively on the final choice, affecting accuracy, reliability, longevity, service costs and therefore overall total cost of ownership.

4 Retrofit Force Sensor Systems Retrofit force sensor systems involve the fitting of special strain sensors to appropriate parts of the load-bearing structure of the vessel, effectively converting these into very large load cells. The sensors are typically welded, bolted or glued to the structure and the success (or failure) of such systems is dependent on a number of key factors. A major drawback can be the stability and magnitude of signal levels received from the sensors. Normally load cells are designed to optimise their electrical output relative to the applied bending, compressive or shear loads and their metallurgical properties are very carefully controlled via heat treatment and machining. During manufacture, the strain gauges are applied to the sensor bodies under ultra-clean laboratory conditions and temperature compensation is an integral part of the manufacturing process. Capacities are selected for specific applications and special mounting arrangements ensure loads are introduced correctly, minimising the effects of side or off-axis loads. By contrast, vessel support structures are typically made from standard non-heat treated steels, selected to optimise system integrity and minimise bending and deflection. As a result the signal levels from the applied sensors are typically very low compared with load cells, making them more prone to structural anomalies and temperature fluctuations. A separate problem can arise where two or more vessels are mounted on a common support structure. So-called structural crosstalk can mean that weight readings from one vessel can be affected by load changes in an adjacent vessel. Although retrofit systems have their limitations, there are ones which utilise structural monitoring expertise together with data-logging techniques to provide very stable and reliable results for some applications. Retrofit sensor systems are non-intrusive and can be fitted without stopping the process. Strain Gauge Load Cell Systems Although the fitting of load cells may appear to be the ideal solution and provide the best accuracy, commercial and engineering restrictions significantly limit their application on high capacity vessels. Fitting load cell assemblies to existing vessels is very process-intrusive and usually requires significant and expensive engineering work to be carried out. Maintaining structural integrity is a major consideration, especially in applications subject to high winds or seismic activity. Depending on the design of the vessel and its location, in certain applications it may not be physically possible to fit load cells (for example on skirted silos or particularly tall silos).

5 Level Measurement Systems Before instrument-based measurement became widely used, content levels were often determined by rudimentary mechanical means. Simple methods such as dropping weighted lengths of rope with equally spaced knots onto the surface of the material in the vessel were not uncommon. Level measuring technologies have advanced considerably over the past two decades and are now well established for measuring the contents of tanks, hoppers, bins and silos up to 100m high. They provide a relatively non-intrusive, easy-to-fit system for products such as cement, hot bitumen, chemicals, plastics, cornflakes, limestone, aggregates, animal feed, flour and oil. Installations range from single point high- or low-level alarm systems to fully integrated multi-point and multi-technology plantwide level measuring systems. Technologies available include: Ultrasonics TDR Guided Microwave Radar Microwave Paddle switch Plumb-bob/Yo-Yo Tuning Fork Capacitance Admittance Vibrating Probe A wide range of critical factors need to be considered when choosing a solids level measuring system, in order to ensure satisfactory results and performance. The key considerations are: Product characteristics (dust, dielectric constant, bulk density, flow behaviour) Vessel environment (temperature, pressure) Size, shape and internal structure of vessel Presence of mixers, aerators or stirrers Operational requirements Filling and emptying points (location and number)

6 Product behaviours within a vessel (including flow characteristics, bulk density and the tendency to absorb moisture) have a major effect on the performance of any level measuring system. The topography of the surface of the material will change as product is added or taken out of the vessel, thereby affecting the results of any measurements. As a result consideration must be given to how the product behaves inside the silo (something that would not be an issue with load cell devices). This could include: Angle of repose Draw-down (opposite of repose) Rat-holing Bridging Bulk Density Dielectric value Angle of Repose / Draw-Down The shape the top of the material forms when it comes to rest inside a vessel is dependent on several factors: its flow characteristics, number and position of fill points and the internal surface finish of the vessel. Similarly the draw-down shape depends on the number of outlet points and positions, and the shape of the bottom of the vessel. Some examples are shown above. Even geographical location can affect what the product does inside a vessel. Prevailing winds can cool one side more than the other; one side may be in direct sunlight whilst another is in the shade. This could lead to moisture or condensation forming on one inside wall causing the product to stick on that side, which may cause the angle of repose or rat-holing / bridging as described below.

7 Rat-Holing This typically occurs when the material in the middle of the silo collapses to the empty point(s) leaving a long hole in the vessel with the remaining material stuck round the sides. Depending on the level measurement technology used and the position of the sensor, inaccurate results can occur. Contents should best be monitored to prevent rat-holing from occurring. In the example to the right probe (A) detects 80% full, whilst probe (B) detects 50% full, leading to confusion. A solution is to use both probe positions and take an average level reading from them. Bridging If product has a tendency to bridge across a silo as material is drawn off, non-contact level measurement equipment will be fooled into providing false levels until the bridge collapses. This can be caused by a number of factors including the tendency of the material to stick or clump together. See example, left. With product that is known to bridge, vessels are often equipped with compressed air cannons or vibrating pads to help break up the clumped product. Bulk Density Changes in bulk density can have a significant effect on the measured levels of powdered product in a vessel. Bulk density is both time-dependent and level-dependent. For example the level in a freshly filled cement silo will change with time as the material settles. In parallel to this issue bulk density will vary from the bottom of the vessel to the top. Any aeration used to keep the contents of a vessel fluidised will also impact on accuracy. Dielectric Constant The dielectric constant of a material is a measure of the extent to which it concentrates electric flux, and is the electrical equivalent of relative magnetic permeability. For Radar and TDR based level measurement systems the intensity of the reflection of the microwave beam is dependent on the dielectric constant of the material. The higher the dielectric constant the stronger the reflection will be: for example the dielectric constant of water is 80 meaning that it is highly reflective. However, unlike the factors above, dielectric constant does not directly influence the accuracy of the measurement but it should still be taken into consideration as it may have bearing on the choice of technology.

8 Vessel Design The design and configuration of the vessel require careful consideration when choosing the most suitable level measurement technology. Common designs include: Vertical tanks Skirted silos Hoppers Chutes Bins For symmetrical vertical tanks, measured levels are proportional to contents over most of the range. However, if it is required to accurately measure contents as levels fall into coned areas at the base of the vessel, appropriate corrections must be made. This consideration can be more relevant for smaller hoppers where any cone is a more prominent part of the design. Internal Structure Depending on the chosen level measurement technology, internal structures such as braces, internal ladders, grills and cross beams can affect accuracy at different points as the vessel empties and fills. The presence of mixers, stirrers and aerators will also need careful consideration as these too can have an effect on accuracy. How Do You Decide Which Technology is Best for Your Application? Level measurement techniques fall into two basic categories: Point Measurement Continuous Measurement In turn, continuous measurement techniques are broadly divided into contact and non-contact technologies. Products may have unique properties which will play a role in determining the effectiveness and performance of any level measuring system and should therefore be carefully considered. In parallel, vessels differ in size and design a typical silo can be ten metres or greater in height whilst bins and hoppers are usually smaller and may act as intermediate product buffers between inventory and daily production.

9 Point Measurement Technologies include: paddle switch, conductivity probes, vibrating probe, admittance and capacitance. Point measurement is a cost-effective solution for simple level measurement where, for example, the user may only need to know when the vessel is empty or full. A typical system for this would involve two sensor switches one at or near the top of the vessel, the second at some point near the bottom. These provide what is often known as a simple High-Low level alarm system. However a fundamental issue with point level switches is that in order to function they must come into contact with the vessel's contents leaving them vulnerable to abrasion and wear, or becoming coated in product which can also damage the device or interfere with its effective operation. Self-cleaning designs and special coatings have been developed to help overcome these problems. Point measurement technology is also often used as part of a continuous level measurement package to provide a complete belt and braces safety system. Continuous Measurement Technologies include: ultrasonics, TDR guided microwave, radar Continuous level measurement has the advantage that it provides real-time level data over the complete measuring range. Measuring liquid levels is usually quite straightforward and accuracies of 0.25% or better can be achieved under stable conditions. However it should be noted that measuring solid and powder contents can present more challenging problems. The characteristics of these technologies are outlined below: Ultrasonics Ultrasonic technology provides a highly cost-effective, easy-to-install, non-contact solution for many solids level measurement applications. The transducer emits pulses of high frequency sound and measures the time it takes for these pulses to be reflected back to the transducer from the material surface. As the speed of sound through air is a known constant the time-of-flight can easily be converted to distance, and from that an accurate level can be extrapolated. Frequencies as low as 5 khz are used on long range solids materials and higher frequencies at 40 khz or above are used on shorter ranges. The latest low frequency ultrasonics can be used for ranges of up to 60m though a number of environmental and operational factors within the silo can reduce this range. Traditional ultrasonic devices struggled with the effects of false echoes and temperature changes but

10 the latest corrective software can compensate for a number of adverse operational factors relating to weak and false echoes caused by dust, internal silo structures (for example ladders or cross braces) and temperature changes affecting time-of-flight. It should be noted that when using ultrasonics, consideration has to be given to the so-called dead band, a range directly below the transducer face where measurement is not possible. This area can vary from 300mm to 1500mm depending on the frequency being transmitted. This usually only presents a problem for shorter measurement ranges and can be overcome using stand pipes to move the ultrasonic transducer up from the top of the tank. TDR (Time Domain Reflectometry) TDR guided microwave technology provides highly effective solutions for solids applications where ultrasonics are not suitable. A key issue is that this technology is unaffected by dust or changes in pressure, temperature or viscosity. The measurement principle is based around a microwave pulse that follows a guided conductor (typically a stainless steel rope or rod), suspended from the top of the silo. This pulse continues down the conductor until it hits the product surface, whereupon it is reflected back up the wave guide. The distance is then calculated using the time-of-flight measurement principle, which in turn allows the level to be calculated. The strength of the reflection is dependent on the dielectric constant of the material being measured. With measuring ranges up to 35m, TDR has the advantage of being relatively low in cost and easy to set up. The bottom of the cable is sometimes anchored to ensure it does not move around during material filling or draw down because if the cable touches the side of the silo it will report false measurements. An important advantage is that the complete system can be configured at the factory prior to fitting, saving valuable time on site. In addition this technology will continue to work even if the wave guide cable or rod becomes coated in product. The main disadvantage is that it is a contact-based technology and may not be suitable for certain applications where, for example, product contamination has to be avoided or abrasion could limit the life of the probe.

11 Radar FMCW (Frequency Modulated Continuous Wave) Radar level measurement systems use high frequency microwave signals (24-26 GHz) that are unaffected by dust, pressure, temperature, viscosity, vacuum or foam. The measured level is proportional to the difference in frequency between the transmitted and the received microwaves. This technology is suitable for measurement ranges up to 80m and provides high levels of accuracy for certain applications; however the effectiveness of Radar technology is dependent on the dielectric constant of the material in the vessel. Radar usually works better on products with a dielectric constant of greater than 2.0. Radar is more expensive than ultrasonics (in some instances up to twice as expensive), which may be a deciding factor for certain applications. Effects of Filling and Emptying It is important to understand the way in which silos are filled and emptied when installing level measurement systems in order to optimise performance. In a normal silo with a width of less than 3 metres, with a centrally-located single fill and draw-off points, the way in which material behaves is usually repeatable. A single level probe, located away from the fill point, will provide reliable and consistent results as illustrated, right. Please note that usually the optimum position to place the probe is at distance one third radius from the outside of the vessel. This will then provide a reliable average level result. Complications can occur with vessels that have multiple fill and draw-off points - for example in quarry screen-houses as shown in illustrations on the following page. The three drain points at the bottom of the bin in this example will cause the product to behave in unpredictable ways. This means that a single sensor located on one side or the other of the vessel will not provide an accurate gauge of the contents for example product may come to rest largely on one side of the bin, and a meter located on opposite side may erroneously show the tank to be empty or near-empty. Using the vessel shown in example 1, this would be the case for a probe located at point (B).

12 Please note that due to the design of screen-houses, where crushed rocks are passed over a series of screens that runs down the centre of the building, it is not possible to centrally-locate a probe in a screen-house - the falling product would soon erode it away. Whilst covers could be fitted it would be totally impractical to gain access in order to service and conduct maintenance on the probe. Example 1: Example 2: The most effective solution is to mount two level meters, each an equal distance from each side in the examples above this would be at points (A) and (B). The readings from each meter are then used to discern the average product height in the vessel. This is done simply by feeding the information from the two probes to to a site PLC or locally-mounted display panel where the readings from (A) and (B) are added together then divided by two, giving an average contents level for the vessel. This also provides the user with separate levels for both sides of the screen, making it easier to decide which point to draw the product from for instance, in example 2 above the product should be taken from draw-off points (1) and (3) to lower the product height at the sides of the bin. In most applications filling is carried out over a relatively short period and then left until needed, however in some process applications material is continually filling and being drained from the silo. This will affect the product behaviour in the vessel, and may also cause additional wear on contact-based level equipment.

13 Conclusion As we have seen, there are a wide range of level measurement equipment options to choose from, and an even wider range of material and process considerations that need to be made in choosing the right one. Solids level monitoring is, by its very nature, very different to monitoring liquid levels unlike solid materials which will pile and fall in difficult-to-predict ways, liquids will find their own level and a meter should get consistent readings wherever it is placed in the vessel. That said, there are an equal number of factors to consider in liquid level measurement, including structural interference, vapours, temperatures and dielectric constants these will be dealt with in a separate paper. As was touched on at the start of this paper, the end user must ultimately has to make key decisions concerning their level monitoring and control system including the following: What is the goal? What information is required? (For example point or continuous level measurement) How should this information be implemented? Who needs to know what the vessel contents are and can it be provided? Consideration also must be given to the properties of the material being measured and any elements in the larger working environment which may affect the accuracy and reliability of the technology being used. In short, whilst there is an answer for almost every level monitoring and control question, there is no one-size-fits-all solution. The technology chosen should be tailored to the application. This is best done in consultation with experienced, competent level measurement engineers. Poorly chosen equipment selected on cost considerations alone will almost certainly lead to further headaches down the line. Correctlychosen equipment will if properly installed, calibrated and maintained provide the best results both in terms of the accuracy and reliability of readings and in lower total cost of ownership for a far longer period of time.

14 Addendum - Product / Technology Reference Table Mode Product Technology Point / Continuous Powders Plastics Slurries Flakes Aggregates Bitumen Paddle Switch P X X X Conductivity Switch P X Vibrating Probe P X X X X Admittance Switch P X X X X X Capacitance Switch P X X X X X Microwave Switch P X X X Plumb-Bob C X Ultrasonic C X X X X X TDR C X X X X X X Radar C X X X X X

15 Appendix System Accuracy / Repeatability / Resolution Accuracy requirements for level measuring systems vary considerably according to business and operational factors. One key issue is to establish whether the user needs to know the LEVEL, the VOLUME or the WEIGHT of the contents in the vessel. Volume and weight can be calculated from level data, but the accuracy of such calculations depends on a number of factors: If LEVEL is required, then the device accuracy will become the overall accuracy, If VOLUME is required the accuracy of the volume calculation will impact on the overall accuracy and If WEIGHT is required both the volume calculation and the accuracy of the bulk density will affect the overall accuracy. In all of the above cases, the overall accuracy will be affected by how the product behaves during filling and emptying. Repeatability is the expectation that if the product reaches the same measurement distance today as it did yesterday, the displayed value will be the same. With a liquid product this is pretty much true. However, where VOLUME or WEIGHT of a solid is required, the way the product behaves in the vessel and the position of the level device will both have a direct effect on the overall repeatability. Resolution is defined as the smallest step change in distance that a level device will respond to. Accuracy, repeatability and resolution are key parameters for any measurement sensor. Whilst they are very relevant to the measurement of silo contents, they are only part of the story as we have seen. About Hycontrol Established in 1983, Hycontrol Limited is one of the UK s leading manufacturers of level measurement equipment. Hycontrol equipment can be found in the widest imaginable variety of industrial processes around the world, controlling and monitoring everything from cornflakes to nuclear waste. The company specializes in silo protection and manufactures a globally unique, patented range of foam detection equipment, as well as providing on-site installation and technical support. More information can be found on-line at

16 To read more of our applications in the chemical, food & beverage, nuclear, water & waste, recycling, quarrying and metals industries, please go online at hycontrol.com Hycontrol UK (Head Office) Orchard Street Redditch Worcestershire England B98 7DP Tel: +44 (0) Fax: +44 (0) Web: Hycontrol China Room N601 Peking Times Square Hui Zhong Li Chao Yang District Beijing China Tel: Fax: Web:.cn

Instrumentation & Data Acquisition Systems

Instrumentation & Data Acquisition Systems Section 3 -Level Robert W. Harrison, PE Bob@TheHarrisonHouse.com Made in USA 1 Level Section Question Which level measuring technology is the best solution when

Instrumentation & Data Acquisition Systems Section 3 -Level Robert W. Harrison, PE Bob@TheHarrisonHouse.com Made in USA 1 Level Section Question Which level measuring technology is the best solution when

Level MEASUREMENT 1/2016

Level MEASUREMENT 1/2016 AGENDA 2 A. Introduction B. Float method C. Displacer method D. Hydrostatic pressure method E. Capacitance method G. Ultrasonic method H. Radar method I. Laser method J. Level

Level MEASUREMENT 1/2016 AGENDA 2 A. Introduction B. Float method C. Displacer method D. Hydrostatic pressure method E. Capacitance method G. Ultrasonic method H. Radar method I. Laser method J. Level

Shanghai AEAD Technology Co., Ltd Professional Manufacturer of Flow, Level, Pressure, Temperature

Shanghai AEAD Technology Co., Ltd Professional Manufacturer of Flow, Level, Pressure, Temperature Tel: 86-21-5197 8797 Fax: 86-21-5197 8799 Email: shaead@163.com Site: www.shaead.com/english Flow Meter

Shanghai AEAD Technology Co., Ltd Professional Manufacturer of Flow, Level, Pressure, Temperature Tel: 86-21-5197 8797 Fax: 86-21-5197 8799 Email: shaead@163.com Site: www.shaead.com/english Flow Meter

White Paper: Preventing Disasters in Bulk Storage Silos through Comprehensive Servicing

White Paper: Preventing Disasters in Bulk Storage Silos through Comprehensive Servicing Preventing Disasters in Bulk Storage Silos through Comprehensive Servicing Best practice for preventing over-pressurisation

White Paper: Preventing Disasters in Bulk Storage Silos through Comprehensive Servicing Preventing Disasters in Bulk Storage Silos through Comprehensive Servicing Best practice for preventing over-pressurisation

Radar, Ultrasonic and RF Level Transmitters

Radar, Ultrasonic and RF Level Transmitters Both measures the time it takes the wave to travel between the transmitter and that reflected wave off the surface of the material to reach the transmitter again.

Radar, Ultrasonic and RF Level Transmitters Both measures the time it takes the wave to travel between the transmitter and that reflected wave off the surface of the material to reach the transmitter again.

Structural Design of Tank Weighing Systems

Structural Design of Tank Weighing Systems 1. Initial observations Some essential rules must be followed when installing load cells in tanks. For example, tanks are frequently subject to weather conditions

Structural Design of Tank Weighing Systems 1. Initial observations Some essential rules must be followed when installing load cells in tanks. For example, tanks are frequently subject to weather conditions

Best Practice for Calibrating LTH Conductivity Instruments

Application Note Best Practice for Calibrating LTH Conductivity Instruments As accurate process measurement becomes an everyday requirement it is vital to be able to calibrate conductivity instruments

Application Note Best Practice for Calibrating LTH Conductivity Instruments As accurate process measurement becomes an everyday requirement it is vital to be able to calibrate conductivity instruments

Best Practices in Measuring Tank Level

Whitepaper Best Practices in Measuring Tank Level What to Know About Measuring Tank Level OVERVIEW Whether you are looking for a solution to solve a water supply issue to a building or trying to monitor

Whitepaper Best Practices in Measuring Tank Level What to Know About Measuring Tank Level OVERVIEW Whether you are looking for a solution to solve a water supply issue to a building or trying to monitor

Guided Wave Radar in Solid Level Applications

Technical Note Rosemount 5300 Series Guided Wave Radar in Solid Level Applications KEY POINTS Measuring Range Probe End Projection function (PEP) Tensile Strength and Collapse Load Mounting Considerations

Technical Note Rosemount 5300 Series Guided Wave Radar in Solid Level Applications KEY POINTS Measuring Range Probe End Projection function (PEP) Tensile Strength and Collapse Load Mounting Considerations

ACCURACY, PERFORMANCE, AND HANDLING OF OIL-FILLED DIGIQUARTZ PRESSURE INSTRUMENTATION

Application Note Doc. G8108-001 Rev. A - 23-Jul-02 ACCURACY, PERFORMANCE, AND HANDLING OF OIL-FILLED DIGIQUARTZ PRESSURE INSTRUMENTATION For more information regarding Digiquartz products contact: Paroscientific,

Application Note Doc. G8108-001 Rev. A - 23-Jul-02 ACCURACY, PERFORMANCE, AND HANDLING OF OIL-FILLED DIGIQUARTZ PRESSURE INSTRUMENTATION For more information regarding Digiquartz products contact: Paroscientific,

Point level switches for safety systems

Point level switches for safety systems By: Bill Sholette Level Products Business Manager Northeast US - Endress+Hauser Point level switches are often used in applications designed to prevent accidents.

Point level switches for safety systems By: Bill Sholette Level Products Business Manager Northeast US - Endress+Hauser Point level switches are often used in applications designed to prevent accidents.

Ultrasonic level transmitter and indicator

Ultrasonic level transmitter and indicator No contact with the product Compact design with polycarbonate housing (electronics and display). Remote display available on request Very good resistance in corrosive

Ultrasonic level transmitter and indicator No contact with the product Compact design with polycarbonate housing (electronics and display). Remote display available on request Very good resistance in corrosive

Level transmitters and indicators Series LU Ultrasonic level transmitter and indicator for liquids and solids

Level transmitters and indicators Series LU Ultrasonic level transmitter and indicator for liquids and solids No contact with the product Compact design with polycarbonate housing (electronics and display).

Level transmitters and indicators Series LU Ultrasonic level transmitter and indicator for liquids and solids No contact with the product Compact design with polycarbonate housing (electronics and display).

TEK-SUB 4800B. Submersible Level Transmitter. Flow Level Temperature Pressure Valves Analyzers Accessories TekValSys LEVEL

Technology Solutions TEK-SUB 4800B Submersible Level Transmitter LEVEL Flow Level Temperature Pressure Valves Analyzers Accessories TekValSys Introduction The Tek-Sub 4800B Submersible Level Transmitter

Technology Solutions TEK-SUB 4800B Submersible Level Transmitter LEVEL Flow Level Temperature Pressure Valves Analyzers Accessories TekValSys Introduction The Tek-Sub 4800B Submersible Level Transmitter

Technology Review Level Measurement of Bulk Solids in Bins, Silos and Hoppers

Technology Review Level Measurement of Bulk Solids in Bins, Silos and Hoppers Joseph D. Lewis, Sr. Vice President Marketing & Sales December 2004 Introduction Trying to measure the level of bulk solids

Technology Review Level Measurement of Bulk Solids in Bins, Silos and Hoppers Joseph D. Lewis, Sr. Vice President Marketing & Sales December 2004 Introduction Trying to measure the level of bulk solids

LEVEL MEASUREMENT TECHNOLOGIES In The Process Control Industry

LEVEL MEASUREMENT TECHNOLOGIES In The Process Control Industry Few things are as ubiquitous in the process control industry as the need to measure the level of a process material in a container. Whether

LEVEL MEASUREMENT TECHNOLOGIES In The Process Control Industry Few things are as ubiquitous in the process control industry as the need to measure the level of a process material in a container. Whether

Pneumatic blending in a bin or silo that is, aerating. Saving time, labor, and money with pneumatic batch blending

As appeared in January 2013 PBE www.powderbulk.com Saving time, labor, and money with pneumatic batch blending Mike Weyandt Nol-Tec Systems With a pneumatic blender, you can mix batches of dry bulk materials

As appeared in January 2013 PBE www.powderbulk.com Saving time, labor, and money with pneumatic batch blending Mike Weyandt Nol-Tec Systems With a pneumatic blender, you can mix batches of dry bulk materials

T EK-COR 1100A. Coriolis Mass Flowmeter. FLOW. Technology Solutions

Technology Solutions T EK-COR 1100A Coriolis Mass Flowmeter FLOW www.tek-trol.com Flow Level Temperature Pressure Valves Analyzers Accessories TekValSys Introduction There can often be more than one type

Technology Solutions T EK-COR 1100A Coriolis Mass Flowmeter FLOW www.tek-trol.com Flow Level Temperature Pressure Valves Analyzers Accessories TekValSys Introduction There can often be more than one type

Maintenance and Troubleshooting of Pneumatic Conveying Systems for Sand in a Foundry

Maintenance and Troubleshooting of Pneumatic Conveying Systems for Sand in a Foundry Article Takeaways: Chris Doerschlag President ALB Klein Technology Group www.albkleinco.com 1. Troubleshooting Guide

Maintenance and Troubleshooting of Pneumatic Conveying Systems for Sand in a Foundry Article Takeaways: Chris Doerschlag President ALB Klein Technology Group www.albkleinco.com 1. Troubleshooting Guide

Pneumatic blending in a bin or silo that is, aerating. Saving time, labor, and money with pneumatic batch blending. Copyright CSC Publishing

As appeared in January 2013 PBE Copyright CSC Publishing www.powderbulk.com Saving time, labor, and money with pneumatic batch blending Mike Weyandt Nol-Tec Systems With a pneumatic blender, you can mix

As appeared in January 2013 PBE Copyright CSC Publishing www.powderbulk.com Saving time, labor, and money with pneumatic batch blending Mike Weyandt Nol-Tec Systems With a pneumatic blender, you can mix

Royce Interface Level Analyzer and Sensors

Royce Interface Level Analyzer and Sensors Model 2511A Interface Level Analyzer The Model 2511A is capable of having the ultrasonic speed of sound signal from its transducers changed by the user in applications

Royce Interface Level Analyzer and Sensors Model 2511A Interface Level Analyzer The Model 2511A is capable of having the ultrasonic speed of sound signal from its transducers changed by the user in applications

Drilling Efficiency Utilizing Coriolis Flow Technology

Session 12: Drilling Efficiency Utilizing Coriolis Flow Technology Clement Cabanayan Emerson Process Management Abstract Continuous, accurate and reliable measurement of drilling fluid volumes and densities

Session 12: Drilling Efficiency Utilizing Coriolis Flow Technology Clement Cabanayan Emerson Process Management Abstract Continuous, accurate and reliable measurement of drilling fluid volumes and densities

General Accreditation Guidance. User checks and maintenance of laboratory balances

General Accreditation Guidance User checks and maintenance of laboratory balances January 2018 Copyright National Association of Testing Authorities, Australia 2010 All intellectual property rights in

General Accreditation Guidance User checks and maintenance of laboratory balances January 2018 Copyright National Association of Testing Authorities, Australia 2010 All intellectual property rights in

LS-UT Ultrasonic Level Transmitter

Four Elms Road Edenbridge Kent TN8 6AB UK Features & Benefits Maintenance free Simple set-up procedure IP86 housing (2m for 24 hours) Low consumption Locking nut supplied Technical Overview The LS-UL ultrasonic

Four Elms Road Edenbridge Kent TN8 6AB UK Features & Benefits Maintenance free Simple set-up procedure IP86 housing (2m for 24 hours) Low consumption Locking nut supplied Technical Overview The LS-UL ultrasonic

Best Practice Guide, Servomex 2700

For full installations details refer to the. Best Practice Guide, Servomex 2700 Mounting: General Guidelines: Servomex 2700 Control Units and air supplies (utilities units) should, ideally, be mounted

For full installations details refer to the. Best Practice Guide, Servomex 2700 Mounting: General Guidelines: Servomex 2700 Control Units and air supplies (utilities units) should, ideally, be mounted

Improve Process Reliability

Convenient Conductivity Calibration to Meet Pharmacopeia Regulations Pharmacopeias require that conductivity measurement systems be periodically calibrated to ensure their precision. The range of accessories

Convenient Conductivity Calibration to Meet Pharmacopeia Regulations Pharmacopeias require that conductivity measurement systems be periodically calibrated to ensure their precision. The range of accessories

SPWE Series. Setup Instructions. Version 2.0

SPWE Series Integrated Tank Weighing Assembly Setup Instructions Version 2.0 Load Cell Central follows a policy of continuous improvement and reserves the right to change specifications without notice.

SPWE Series Integrated Tank Weighing Assembly Setup Instructions Version 2.0 Load Cell Central follows a policy of continuous improvement and reserves the right to change specifications without notice.

SPECIFYING MOTIONLESS MIXERS

SPECIFYING MOTIONLESS MIXERS The operating cost for the energy necessary to mix fluids with a motionless mixer is usually far lower than for any competitive mixing technique. An extruder which melts, mixes

SPECIFYING MOTIONLESS MIXERS The operating cost for the energy necessary to mix fluids with a motionless mixer is usually far lower than for any competitive mixing technique. An extruder which melts, mixes

Gerald D. Anderson. Education Technical Specialist

Gerald D. Anderson Education Technical Specialist The factors which influence selection of equipment for a liquid level control loop interact significantly. Analyses of these factors and their interactions

Gerald D. Anderson Education Technical Specialist The factors which influence selection of equipment for a liquid level control loop interact significantly. Analyses of these factors and their interactions

deltaflowc deltaflowc Venturi or Probe

deltaflowc Mass Flowmeter for Gases - Multivariable with ultra fast dp, p and T-sensors - Compact, accurate and user-friendly - Ideal for OEMs deltaflowc Venturi or Probe Precise mass flow metering deltaflowc

deltaflowc Mass Flowmeter for Gases - Multivariable with ultra fast dp, p and T-sensors - Compact, accurate and user-friendly - Ideal for OEMs deltaflowc Venturi or Probe Precise mass flow metering deltaflowc

WP Eliminating Oxygen from the Purge Gas and the use of Monitoring Equipment

Part 4 WP - 269 Eliminating Oxygen from the Purge Gas and the use of Monitoring Equipment Even using specialised weld purging equipment does not guarantee defect free welds. Control of the oxygen content

Part 4 WP - 269 Eliminating Oxygen from the Purge Gas and the use of Monitoring Equipment Even using specialised weld purging equipment does not guarantee defect free welds. Control of the oxygen content

TS1. Ultrasonic Tank Sender. Installation and Operating Instructions. For TS1 Firmware v3.8. Page 1 INST-TS1-V13 18/11/10

TS1 Ultrasonic Tank Sender Installation and Operating Instructions For TS1 Firmware v3.8 Page 1 Table of Contents 1. FEATURES... 3 2. SPECIFICATIONS... 3 3. DIMENSIONS... 4 4. MOUNTING AND INSTALLATION...

TS1 Ultrasonic Tank Sender Installation and Operating Instructions For TS1 Firmware v3.8 Page 1 Table of Contents 1. FEATURES... 3 2. SPECIFICATIONS... 3 3. DIMENSIONS... 4 4. MOUNTING AND INSTALLATION...

Electro Controls. Level WattsIndustries.co.uk

Electro Controls Level - 2017 WattsIndustries.co.uk levels Section 19 LIQUID LEVEL SWITCHES HORIZONTAL ELL.. Volt free contacts To monitor liquid level in tanks and switch pumps or an alarm in the event

Electro Controls Level - 2017 WattsIndustries.co.uk levels Section 19 LIQUID LEVEL SWITCHES HORIZONTAL ELL.. Volt free contacts To monitor liquid level in tanks and switch pumps or an alarm in the event

Coriolis Mass Flow Meter

Coriolis Mass Flow Meter TMFW Series Mini Type Coriolis Mass Flow Meter Xi an Tosilon Automation Co., Ltd No.299, Daqing Rd, Lianhu District, Xi'an Shaanxi, China Tel: +86-29-8823 8550 info@tosilon.com;

Coriolis Mass Flow Meter TMFW Series Mini Type Coriolis Mass Flow Meter Xi an Tosilon Automation Co., Ltd No.299, Daqing Rd, Lianhu District, Xi'an Shaanxi, China Tel: +86-29-8823 8550 info@tosilon.com;

Measurement And Control Appreciation

Measurement And Control Appreciation Course Content Aim To provide an appreciation of the operation and application of process plant instrumentation used for the measurement and display of the main process

Measurement And Control Appreciation Course Content Aim To provide an appreciation of the operation and application of process plant instrumentation used for the measurement and display of the main process

Accuracy under pressure.

GE Oil & Gas Accuracy under pressure. Hydrology data you can rely on, time after time. GE Pressure Sensors for Hydrology applications: UNIK5000 family TERPS 8000 series 1800 series GE have been manufacturing

GE Oil & Gas Accuracy under pressure. Hydrology data you can rely on, time after time. GE Pressure Sensors for Hydrology applications: UNIK5000 family TERPS 8000 series 1800 series GE have been manufacturing

Liquid Level Measurement

Technical Article Liquid Level Measurement A pressure transmitter can be used to determine the liquid level in a tank, well, river or other body of liquid. The pressure at the bottom of a liquid filled

Technical Article Liquid Level Measurement A pressure transmitter can be used to determine the liquid level in a tank, well, river or other body of liquid. The pressure at the bottom of a liquid filled

How to specify a product. Process Sensors and Mechanical Instruments

How to specify a product Process Sensors and Mechanical Instruments Keep the overview. Here is some guideline information on how to specify our products. Intended as supplementary help to specification

How to specify a product Process Sensors and Mechanical Instruments Keep the overview. Here is some guideline information on how to specify our products. Intended as supplementary help to specification

Membrane modules for nitrogen and oxygen generator systems. Technology Overview ENGINEERING YOUR SUCCESS.

Membrane modules for nitrogen and oxygen generator systems Technology Overview ENGINEERING YOUR SUCCESS. Parker modules the heart of OEM tailor-made nitrogen generators OEM (Original Equipment Manufacturer)

Membrane modules for nitrogen and oxygen generator systems Technology Overview ENGINEERING YOUR SUCCESS. Parker modules the heart of OEM tailor-made nitrogen generators OEM (Original Equipment Manufacturer)

HEATEC TEC-NOTE Publication No Revised

HEATEC TEC-NOTE Revised 6-17-10 Setting up Vega radar sensors for Heatec vertical asphalt tanks This document provides information for setting up Vega radar sensors installed on Heatec tanks that store

HEATEC TEC-NOTE Revised 6-17-10 Setting up Vega radar sensors for Heatec vertical asphalt tanks This document provides information for setting up Vega radar sensors installed on Heatec tanks that store

CONTROL and INSTRUMENTATION

CONTROL and INSTRUMENTATION COURSE 500: 5 DAYS: Max 8 Candidates This course covers the key aspects of current instrumentation and process control technology and is designed to enable maintenance personnel

CONTROL and INSTRUMENTATION COURSE 500: 5 DAYS: Max 8 Candidates This course covers the key aspects of current instrumentation and process control technology and is designed to enable maintenance personnel

Manual of SF6 Comprehensive Tester

Manual of SF6 Comprehensive Tester Important Description All the staff taking in charge of the usage or maintenance of this product should carefully read this manual. The same as any other complicated

Manual of SF6 Comprehensive Tester Important Description All the staff taking in charge of the usage or maintenance of this product should carefully read this manual. The same as any other complicated

LVU2800 Series. Ultrasonic Level Transmitter

LVU2800 Series Ultrasonic Level Transmitter 2 of 23 INTRODUCTION / TABLE OF CONTENTS Step One The LVU2800 Series is a general purpose ultrasonic level transmitter that provides a loop powered 4 20 ma output.

LVU2800 Series Ultrasonic Level Transmitter 2 of 23 INTRODUCTION / TABLE OF CONTENTS Step One The LVU2800 Series is a general purpose ultrasonic level transmitter that provides a loop powered 4 20 ma output.

2600T Series Pressure Transmitters Plugged Impulse Line Detection Diagnostic. Pressure Measurement Engineered solutions for all applications

Application Description AG/266PILD-EN Rev. C 2600T Series Pressure Transmitters Plugged Impulse Line Detection Diagnostic Pressure Measurement Engineered solutions for all applications Increase plant productivity

Application Description AG/266PILD-EN Rev. C 2600T Series Pressure Transmitters Plugged Impulse Line Detection Diagnostic Pressure Measurement Engineered solutions for all applications Increase plant productivity

Sandvik Jaw Crushers

Sandvik Jaw Crushers Excellent durability thanks to welded frame. Range including models for mobile applications. 2 The product of decades of experience At Sandvik we have over a century of experience

Sandvik Jaw Crushers Excellent durability thanks to welded frame. Range including models for mobile applications. 2 The product of decades of experience At Sandvik we have over a century of experience

Product information. Capacitive. Level detection in liquid VEGACAP 62 VEGACAP 63 VEGACAP 64 VEGACAP 66 VEGACAP 69. Document ID: 29983

Product information Level detection in liquid VEGACAP 62 VEGACAP 63 VEGACAP 64 VEGACAP 66 VEGACAP 69 Document ID: 29983 Contents Contents 1 Description of the measuring principle... 3 2 Type overview...

Product information Level detection in liquid VEGACAP 62 VEGACAP 63 VEGACAP 64 VEGACAP 66 VEGACAP 69 Document ID: 29983 Contents Contents 1 Description of the measuring principle... 3 2 Type overview...

MODEL WEIGH MODULE

MODEL 65082 WEIGH MODULE INSTALLATION & OPERATING MANUAL P.O. Box 775 - Farmington, NH 03835 Tel: 603-755-3885 email: cands_nh@msn.com www.candscontrols.com Model 65023 Cantilever Beam Transducer Nickel-Plated

MODEL 65082 WEIGH MODULE INSTALLATION & OPERATING MANUAL P.O. Box 775 - Farmington, NH 03835 Tel: 603-755-3885 email: cands_nh@msn.com www.candscontrols.com Model 65023 Cantilever Beam Transducer Nickel-Plated

Ultrasonic. Continuous level measurement. Overview Page 64 VEGASON series 60 Page 66 AL-EN

Ultrasonic Continuous level measurement Overview Page 64 VEGASON series 60 Page 66 6 VEGASON Non-contact measurement with ultrasonics Measuring principle Short ultrasonic pulses in the range of 5 to 70

Ultrasonic Continuous level measurement Overview Page 64 VEGASON series 60 Page 66 6 VEGASON Non-contact measurement with ultrasonics Measuring principle Short ultrasonic pulses in the range of 5 to 70

BAPI Pressure Line of Products - FAQs

Table of Contents 1. Several manufacturers produce pressure transmitters, why should I purchase from BAPI?... p. 2 2. BAPI makes several styles of pressure transmitters. What are the features of each?...

Table of Contents 1. Several manufacturers produce pressure transmitters, why should I purchase from BAPI?... p. 2 2. BAPI makes several styles of pressure transmitters. What are the features of each?...

COMPARISON OF DIFFERENTIAL PRESSURE SENSING TECHNOLOGIES IN HOSPITAL ISOLATION ROOMS AND OTHER CRITICAL ENVIRONMENT APPLICATIONS

COMPARISON OF DIFFERENTIAL PRESSURE SENSING TECHNOLOGIES IN HOSPITAL ISOLATION ROOMS AND OTHER CRITICAL ENVIRONMENT APPLICATIONS APPLICATION NOTE LC-136 Introduction Specialized spaces often times must

COMPARISON OF DIFFERENTIAL PRESSURE SENSING TECHNOLOGIES IN HOSPITAL ISOLATION ROOMS AND OTHER CRITICAL ENVIRONMENT APPLICATIONS APPLICATION NOTE LC-136 Introduction Specialized spaces often times must

Acrison Weighing Systems

Acrison Weighing Systems Theory of Operation Functional Insight s Theory of Operation and Functional Insight During the initial design phase associated with Acrison s pioneering development of a continuous

Acrison Weighing Systems Theory of Operation Functional Insight s Theory of Operation and Functional Insight During the initial design phase associated with Acrison s pioneering development of a continuous

Operating instructions Binary level sensor LI / / 2013

Operating instructions Binary level sensor LI51 UK 704367 / 02 02 / 2013 Contents 1 Preliminary note3 1.1 Symbols used 3 2 Safety instructions 3 3 Functions and features 4 3.1 Application area 4 3.2 Restriction

Operating instructions Binary level sensor LI51 UK 704367 / 02 02 / 2013 Contents 1 Preliminary note3 1.1 Symbols used 3 2 Safety instructions 3 3 Functions and features 4 3.1 Application area 4 3.2 Restriction

Level, Pressure, and Density Instrumentation for the Petrochemical Industry

Level, Pressure, and Density Instrumentation for the Petrochemical Industry Application Examples and Products Measurement technology for the petrochemical industry This brochure presents examples of applied

Level, Pressure, and Density Instrumentation for the Petrochemical Industry Application Examples and Products Measurement technology for the petrochemical industry This brochure presents examples of applied

Precision Liquid Settlement Array Manual

Precision Liquid Settlement Array Manual All efforts have been made to ensure the accuracy and completeness of the information contained in this document. RST Instruments Ltd reserves the right to change

Precision Liquid Settlement Array Manual All efforts have been made to ensure the accuracy and completeness of the information contained in this document. RST Instruments Ltd reserves the right to change

VW Liquid Settlement System VWLSS-200

DATASHEET VW Liquid Settlement System VWLSS-200 The Geosense VWLSS-200 Vibrating Wire Liquid Settlement System is used to monitor settlement or heave in soils and other structures such as embankments,

DATASHEET VW Liquid Settlement System VWLSS-200 The Geosense VWLSS-200 Vibrating Wire Liquid Settlement System is used to monitor settlement or heave in soils and other structures such as embankments,

REVISIONS. App Thom. App Sud. App PC IG 2014/09/19

/5 REVISIONS Rev Description Rev n by Sud PC Thom VB LH Clyd r Act Issue Date YYYY/MM/DD Gen. updates to content, format and spec number. Previously 564-00.0.0 FF 204/09/9 IG 204/09/9 N/A N/A N/A N/A N/A

/5 REVISIONS Rev Description Rev n by Sud PC Thom VB LH Clyd r Act Issue Date YYYY/MM/DD Gen. updates to content, format and spec number. Previously 564-00.0.0 FF 204/09/9 IG 204/09/9 N/A N/A N/A N/A N/A

White Paper. Electrical control valve actuators on oil and gas production separators

White Paper Electrical control valve actuators on oil and gas production separators Electrical control valve actuators on oil and gas production separators White Paper 18 th August 2014 Electrical control

White Paper Electrical control valve actuators on oil and gas production separators Electrical control valve actuators on oil and gas production separators White Paper 18 th August 2014 Electrical control

HEATEC TEC-NOTE. Setting Siemens Pressure Transmitter. Used on Heatec Vertical Asphalt Tanks. Publication No , Revised

HEATEC TEC-NOTE, Revised 1-5-15 Setting Siemens Pressure Transmitter Used on Heatec Vertical Asphalt Tanks This document provides information on setting Siemens pressure transmitters used on Heatec vertical

HEATEC TEC-NOTE, Revised 1-5-15 Setting Siemens Pressure Transmitter Used on Heatec Vertical Asphalt Tanks This document provides information on setting Siemens pressure transmitters used on Heatec vertical

Ez Flo Impact Flow Scale graduates from weighing Baghouse Dust out of an Auger to RAS out of a Feeder Bin.

Ez Flo Impact Flow Scale graduates from weighing Baghouse Dust out of an Auger to RAS out of a Feeder Bin. RAS (Recycled Asphalt Shingles) and RAP over the same Belt Scale; the biggest problem is that

Ez Flo Impact Flow Scale graduates from weighing Baghouse Dust out of an Auger to RAS out of a Feeder Bin. RAS (Recycled Asphalt Shingles) and RAP over the same Belt Scale; the biggest problem is that

Product information. Capacitive. Level detection with bulk solids VEGACAP 62 VEGACAP 65 VEGACAP 66 VEGACAP 67. Document ID: 29982

Product information Level detection with bulk solids VEGACAP 62 VEGACAP 65 VEGACAP 66 VEGACAP 67 Document ID: 29982 Contents Contents 1 Description of the measuring principle... 3 2 Type overview... 5

Product information Level detection with bulk solids VEGACAP 62 VEGACAP 65 VEGACAP 66 VEGACAP 67 Document ID: 29982 Contents Contents 1 Description of the measuring principle... 3 2 Type overview... 5

Point Level Measurement. Switching Technology for Liquid and Solid Level Measurement

Point Level Measurement Switching Technology for Liquid and Solid Level Measurement Contents Leadership in Level Switching 3 About Level Switching 4 plics Easy is Better 6 VEGAVIB 61, 62, and 63 Measurement

Point Level Measurement Switching Technology for Liquid and Solid Level Measurement Contents Leadership in Level Switching 3 About Level Switching 4 plics Easy is Better 6 VEGAVIB 61, 62, and 63 Measurement

Blackwater Sensing: Providing long-term reliability for Blackwater sensors.

Blackwater Sensing: Providing long-term reliability for Blackwater sensors. It is becoming increasingly unacceptable to discharge sewage from a toilet directly into the environment. With legislation also

Blackwater Sensing: Providing long-term reliability for Blackwater sensors. It is becoming increasingly unacceptable to discharge sewage from a toilet directly into the environment. With legislation also

Improving distillation tower operation

Improving distillation tower operation Measuring differential pressure across long sections of distillation columns has always been challenging, but purpose-built sensor systems provide a solution Fast

Improving distillation tower operation Measuring differential pressure across long sections of distillation columns has always been challenging, but purpose-built sensor systems provide a solution Fast

DEVICES FOR FIELD DETERMINATION OF WATER VAPOR IN NATURAL GAS Betsy Murphy MNM Enterprises 801 N. Riverside Drive Fort Worth, Texas 76111

INTRODUCTION Water vapor in natural gas has more than a substantial effect on the quality of the gas stream. Without quality measurement of water vapor the gas is basically not saleable. Contracts are

INTRODUCTION Water vapor in natural gas has more than a substantial effect on the quality of the gas stream. Without quality measurement of water vapor the gas is basically not saleable. Contracts are

TGD-L (LP) Tank Gauging Device TGD L (Level) TGD LP (Level Pressure) Main features:

Product data sheet TGD-L (LP) Main features: Automatic signal self-calibration reflectors in every the tank, 2 seconds the acoustic Less cabling signal only is guided 2 wires in a steel pipe going Non-contact

Product data sheet TGD-L (LP) Main features: Automatic signal self-calibration reflectors in every the tank, 2 seconds the acoustic Less cabling signal only is guided 2 wires in a steel pipe going Non-contact

RAMSTM. 360 Riser and Anchor-Chain Integrity Monitoring for FPSOs

RAMS 360 Riser and Anchor-Chain Integrity Monitoring for FPSOs Introduction to RAMS Tritech s RAMS is a 360 anchor-chain and riser integrity monitoring system for Floating Production Storage and Offloading

RAMS 360 Riser and Anchor-Chain Integrity Monitoring for FPSOs Introduction to RAMS Tritech s RAMS is a 360 anchor-chain and riser integrity monitoring system for Floating Production Storage and Offloading

Truck-mounted Mass Flow Metering for LPG Delivery

Truck-mounted Mass Flow Metering for LPG Delivery Itron, Inc. 1310 Emerald Rd. Greenwood, SC 29646 Introduction The mathematician Gustave De Coriolis first described the Coriolis Effect, which is an inertial

Truck-mounted Mass Flow Metering for LPG Delivery Itron, Inc. 1310 Emerald Rd. Greenwood, SC 29646 Introduction The mathematician Gustave De Coriolis first described the Coriolis Effect, which is an inertial

PASSENGER SHIPS Guidelines for preparation of Hull Structural Surveys

(Feb 2010) PASSENGER SHIPS Guidelines for preparation of Hull Structural Surveys Contents 1 Introduction 2 Preparations for Survey 2.1 General 2.2 Conditions for survey 2.3 Access to structures 2.4 Survey

(Feb 2010) PASSENGER SHIPS Guidelines for preparation of Hull Structural Surveys Contents 1 Introduction 2 Preparations for Survey 2.1 General 2.2 Conditions for survey 2.3 Access to structures 2.4 Survey

STARLOG. Capacitive Water Depth Probe

STARLOG Capacitive Water Depth Probe Model 6521 User Manual Supplement 6219 Revision D July 10. 1998 Copyright Notice Copyright Unidata Australia 1998. All rights reserved. No part of this publication

STARLOG Capacitive Water Depth Probe Model 6521 User Manual Supplement 6219 Revision D July 10. 1998 Copyright Notice Copyright Unidata Australia 1998. All rights reserved. No part of this publication

Mud Diver. Suspended solids level measurement and tank profile station for Clarifier, Thickener, CCD and Washer Control Optimisation

Mud Diver Suspended solids level measurement and tank profile station for Clarifier, Thickener, CCD and Washer Control Optimisation INTRODUCTION INTRODUCTION SmartDiver is a ruggedized automatic mud diver

Mud Diver Suspended solids level measurement and tank profile station for Clarifier, Thickener, CCD and Washer Control Optimisation INTRODUCTION INTRODUCTION SmartDiver is a ruggedized automatic mud diver

NEW VERSAFLOW CORIOLIS

Steffen Baecker June 20, 2017 NEW VERSAFLOW CORIOLIS With Stable Two-phase Flow Measurement Honeywell Internal VersaFlow Flow Technologies Volume flow measurement Conductive fluids only - Water - Chemicals

Steffen Baecker June 20, 2017 NEW VERSAFLOW CORIOLIS With Stable Two-phase Flow Measurement Honeywell Internal VersaFlow Flow Technologies Volume flow measurement Conductive fluids only - Water - Chemicals

HBLT-A1 LIQUID LEVEL SENSOR

Instruction manual HBLT-A1 LIQUID LEVEL SENSOR for measuring liquid level in refrigerant vessels Instruction manual HBLT - A1 - Liquid level Transmitter (HBLT-A1-008-UK) 1 / 16 Contents Safety instructions...

Instruction manual HBLT-A1 LIQUID LEVEL SENSOR for measuring liquid level in refrigerant vessels Instruction manual HBLT - A1 - Liquid level Transmitter (HBLT-A1-008-UK) 1 / 16 Contents Safety instructions...

Locator Locator-D-Lux Air-Saver G1 Air-Saver G2

170663_air_saving_products 17-02-2011 16:42 Pagina 1 Locator Locator-D-Lux Air-Saver G1 Air-Saver G2 AIR SAVING PRODUCTS 170663_air_saving_products 17-02-2011 16:42 Pagina 2 170663_air_saving_products

170663_air_saving_products 17-02-2011 16:42 Pagina 1 Locator Locator-D-Lux Air-Saver G1 Air-Saver G2 AIR SAVING PRODUCTS 170663_air_saving_products 17-02-2011 16:42 Pagina 2 170663_air_saving_products

Pneumatic Conveying Principles BSH&E SEMINAR

Pneumatic Conveying Principles Definition What is Pneumatic Conveying? A method for conveying bulk material using gas (usually air) The material can be blown (pressure systems) or sucked (vacuum systems)

Pneumatic Conveying Principles Definition What is Pneumatic Conveying? A method for conveying bulk material using gas (usually air) The material can be blown (pressure systems) or sucked (vacuum systems)

Non-intrusive Natural Gas Flow Measurement

Non-intrusive Natural Gas Flow Measurement Upstream Midstream Downstream - Gas at the Separator Outlet - Wellhead Gas Flow Measurement - Gas Injection n & Lift - Gas Treatmentent on - Compressor r Stations

Non-intrusive Natural Gas Flow Measurement Upstream Midstream Downstream - Gas at the Separator Outlet - Wellhead Gas Flow Measurement - Gas Injection n & Lift - Gas Treatmentent on - Compressor r Stations

AUTOMATIC HOSE TEST UNIT, TYPE SPU

VALVES AND FITTINGS UP TO 14,000 BAR TEST AND CONTROL EQUIPMENT H IGH PRESSURE TECHNOLOGY AUTOMATIC HOSE TEST UNIT, TYPE SPU Pressure range from 1 up to 10,000 bar User-friendly touch panel operation HIGH-PRESSURE

VALVES AND FITTINGS UP TO 14,000 BAR TEST AND CONTROL EQUIPMENT H IGH PRESSURE TECHNOLOGY AUTOMATIC HOSE TEST UNIT, TYPE SPU Pressure range from 1 up to 10,000 bar User-friendly touch panel operation HIGH-PRESSURE

Cold-acclimatised pipelines

Cold-acclimatised pipelines Maintaining flow and pressure when the temperature is low can present serious but manageable challenges. Field instrumentation can help, but it must be deployed and maintained

Cold-acclimatised pipelines Maintaining flow and pressure when the temperature is low can present serious but manageable challenges. Field instrumentation can help, but it must be deployed and maintained

Vortex flowmeters. Product family introduction Principle of operation Product review Applications Key product features

Vortex flowmeters introduction Product review s Key product features This document should not be duplicated, used, distributed, or disclosed for any purpose unless authorized by Siemens. Page 1 Vortex

Vortex flowmeters introduction Product review s Key product features This document should not be duplicated, used, distributed, or disclosed for any purpose unless authorized by Siemens. Page 1 Vortex

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual Man 188 1.1.0 06/08/2014 Chris Rasmussen Philip Day Chris Rasmussen Manual No. Revision Date Originator Checked Authorised for Issue User

Vibrating Wire Load Cell (3, 4, 5 And 6 Gauge Cells) User Manual Man 188 1.1.0 06/08/2014 Chris Rasmussen Philip Day Chris Rasmussen Manual No. Revision Date Originator Checked Authorised for Issue User

THE PRESSURE SIGNAL CALIBRATION TECHNOLOGY OF THE COMPREHENSIVE TEST

THE PRESSURE SIGNAL CALIBRATION TECHNOLOGY OF THE COMPREHENSIVE TEST SYSTEM Yixiong Xu Mechatronic Engineering, Shanghai University of Engineering Science, Shanghai, China ABSTRACT The pressure signal

THE PRESSURE SIGNAL CALIBRATION TECHNOLOGY OF THE COMPREHENSIVE TEST SYSTEM Yixiong Xu Mechatronic Engineering, Shanghai University of Engineering Science, Shanghai, China ABSTRACT The pressure signal

OPERATOR S MANUAL Ar-Gone Weld Gas Analyzer

July 2011 OPERATOR S MANUAL Ar-Gone Weld Gas Analyzer WARNING! Before operating this product, read and understand this Operator s Manual. Become familiar with the potential hazards of this unit. Contact

July 2011 OPERATOR S MANUAL Ar-Gone Weld Gas Analyzer WARNING! Before operating this product, read and understand this Operator s Manual. Become familiar with the potential hazards of this unit. Contact

Gas Network Craftsperson

Gas Network Craftsperson Unit EIAU06 Maintaining Instrumentation and Control Equipment Circuits This assessment specification has been developed as part of the network maintenance craftsperson standard

Gas Network Craftsperson Unit EIAU06 Maintaining Instrumentation and Control Equipment Circuits This assessment specification has been developed as part of the network maintenance craftsperson standard

Selecting the right pressure sensor for your application

Selecting the right pressure sensor for your application This guide from Acal BFi details the key factors that you must consider when selecting a pressure sensor for your application. Selecting the best

Selecting the right pressure sensor for your application This guide from Acal BFi details the key factors that you must consider when selecting a pressure sensor for your application. Selecting the best

Precision level sensing with low-pressure module MS

The task on hand Level sensing as it is understood in modern process automation is much more than simply "tank half full" or "tank a quarter full". Using suitable sensors, levels, inlets and outlets can

The task on hand Level sensing as it is understood in modern process automation is much more than simply "tank half full" or "tank a quarter full". Using suitable sensors, levels, inlets and outlets can

user leaflet GAUGING TRANSDUCERS

user leaflet Solartron Metrology Gauging Transducers are high precision measurement probes intended for all gauging applications demanding high accuracy and a high degree of repeatability. The one piece

user leaflet Solartron Metrology Gauging Transducers are high precision measurement probes intended for all gauging applications demanding high accuracy and a high degree of repeatability. The one piece

Hydro Plant Risk Assessment Guide

September 2006 Hydro Plant Risk Assessment Guide Appendix E10: Compressed Air System Condition Assessment E10. 1 GENERAL Compressed air systems are key components at hydroelectric power plants. Compressed

September 2006 Hydro Plant Risk Assessment Guide Appendix E10: Compressed Air System Condition Assessment E10. 1 GENERAL Compressed air systems are key components at hydroelectric power plants. Compressed

Pulsed Eddy Current (PEC) Inspection through Insulation

Pulsed Eddy Current (PEC) Inspection through Insulation Inspection through insulation opens unexpected opportunities Shell Global Solutions in Amsterdam has developed over the past few years an inspection

Pulsed Eddy Current (PEC) Inspection through Insulation Inspection through insulation opens unexpected opportunities Shell Global Solutions in Amsterdam has developed over the past few years an inspection

ICE LOADS MONITORING SYSTEMS

Guide for Ice Loads Monitoring Systems GUIDE FOR ICE LOADS MONITORING SYSTEMS MAY 2011 American Bureau of Shipping Incorporated by Act of Legislature of the State of New York 1862 Copyright 2011 American

Guide for Ice Loads Monitoring Systems GUIDE FOR ICE LOADS MONITORING SYSTEMS MAY 2011 American Bureau of Shipping Incorporated by Act of Legislature of the State of New York 1862 Copyright 2011 American

Engineering: Measurement Technology Pressure/Level (SCQF level 6)

National Unit Specification: general information CODE F5KT 12 SUMMARY This Unit can be delivered as part of a National Qualification Group Award but can also be taken as a free-standing Unit. This Unit

National Unit Specification: general information CODE F5KT 12 SUMMARY This Unit can be delivered as part of a National Qualification Group Award but can also be taken as a free-standing Unit. This Unit

Model 575 and 575P Submersible Level Transmitters. Model 675 Submersible Level Transmitters. Model SDT Submersible Level Transmitters

Model 575 and 575P Submersible Level Transmitters Class I, Div 1 Approvals Standard or flush diaphragms for easy of cleaning Measurement ranges up to 690 of water Protected flush option available with

Model 575 and 575P Submersible Level Transmitters Class I, Div 1 Approvals Standard or flush diaphragms for easy of cleaning Measurement ranges up to 690 of water Protected flush option available with

process measurement solutions The level solutions catalogue

process measurement solutions The level solutions catalogue Precision... level measurement & control... Powerful FMCW technology Radar level transmitter MRL700 Radar level transmitters Solartron Mobrey's

process measurement solutions The level solutions catalogue Precision... level measurement & control... Powerful FMCW technology Radar level transmitter MRL700 Radar level transmitters Solartron Mobrey's

Cryostream 800 Series

Cryostream 800 Series Cryostream 800 Series Nearly 30 years after the invention of the first Cryostream Cooler, Oxford Cryosystems is proud to announce the launch of the new 800 series Cryostream. The

Cryostream 800 Series Cryostream 800 Series Nearly 30 years after the invention of the first Cryostream Cooler, Oxford Cryosystems is proud to announce the launch of the new 800 series Cryostream. The

Rotary vane steering gear for smaller vessels

Steering gear Rotary vane steering gear for smaller vessels The SR series is designed with integrated frequency controlled pumps. General description Rolls-Royce supplies a complete range of steering gear,

Steering gear Rotary vane steering gear for smaller vessels The SR series is designed with integrated frequency controlled pumps. General description Rolls-Royce supplies a complete range of steering gear,

The Use of Ultrasonic Inspections at Elevated Temperature

18th World Conference on Nondestructive Testing, 16-20 April 2012, Durban, South Africa The Use of Ultrasonic Inspections at Elevated Temperature Alex McLAY, Jan VERKOOIJEN, TÜV Rheinland Sonovation 4906AZ

18th World Conference on Nondestructive Testing, 16-20 April 2012, Durban, South Africa The Use of Ultrasonic Inspections at Elevated Temperature Alex McLAY, Jan VERKOOIJEN, TÜV Rheinland Sonovation 4906AZ

Operating Instructions of BROSA tension load cells, types 0111, 0113

Operating Instructions of BROSA tension load cells, types 0, 03. Description of BROSA tension load cells. Structure and function The BROSA type 0 and 03 tension load cells transmit and measure the tensile

Operating Instructions of BROSA tension load cells, types 0, 03. Description of BROSA tension load cells. Structure and function The BROSA type 0 and 03 tension load cells transmit and measure the tensile

Vibration Analysis and Test of Backup Roll in Temper Mill

Sensors & Transducers 2013 by IFSA http://www.sensorsportal.com Vibration Analysis and Test of Backup Roll in Temper Mill Yuanmin Xie College of Machinery and Automation, Wuhan University of Science and

Sensors & Transducers 2013 by IFSA http://www.sensorsportal.com Vibration Analysis and Test of Backup Roll in Temper Mill Yuanmin Xie College of Machinery and Automation, Wuhan University of Science and

Process Control Loops

In this section, you will learn about how control components and control algorithms are integrated to create a process control system. Because in some processes many variables must be controlled, and each

In this section, you will learn about how control components and control algorithms are integrated to create a process control system. Because in some processes many variables must be controlled, and each

Owners Manual Release Date: Thursday, December 29, 2011

S MFD/LRL Generators Page 1 Ground Current Generator GCG By Tim Williams Owners Manual Release Date: Thursday, December 29, 2011 This document is subjected to change without any notice. Please check the

S MFD/LRL Generators Page 1 Ground Current Generator GCG By Tim Williams Owners Manual Release Date: Thursday, December 29, 2011 This document is subjected to change without any notice. Please check the

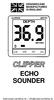

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH METRES ECHO SOUNDER.

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

DESIGNED AND MANUFACTURED IN ENGLAND CLIPPER DEPTH DEPTH 7 METRES ECHO SOUNDER INTRODUCTION 2 INSTALLING THE DISPLAY 2 INSTALLING THE TRANSDUCER 3 NOTES ON ELECTRICAL INTERFERENCE 5 GETTING STARTED 5 OPERATIONAL

WIND CLIPPER KTS ILLUM SCALE INC DEC CLIPPER WIND SYSTEM

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE

CLIPPER WIND KTS ILLUM SCALE DEC INC CLIPPER WIND SYSTEM TABLE OF CONTENTS INTRODUCTION PRE-TEST OF INSTRUMENT INSTALLING THE MASTHEAD SENSOR UNIT INSTALLING THE DISPLAY NORMAL OPERATION CHANGING THE